Double-oxidation, double-loop and double-demisting desulfurization tower and processing device

A process device and double-loop technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of difficult to eliminate aerosol, high operating costs, complex equipment, etc., and achieve product ammonium sulfate compliance, operation and maintenance The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

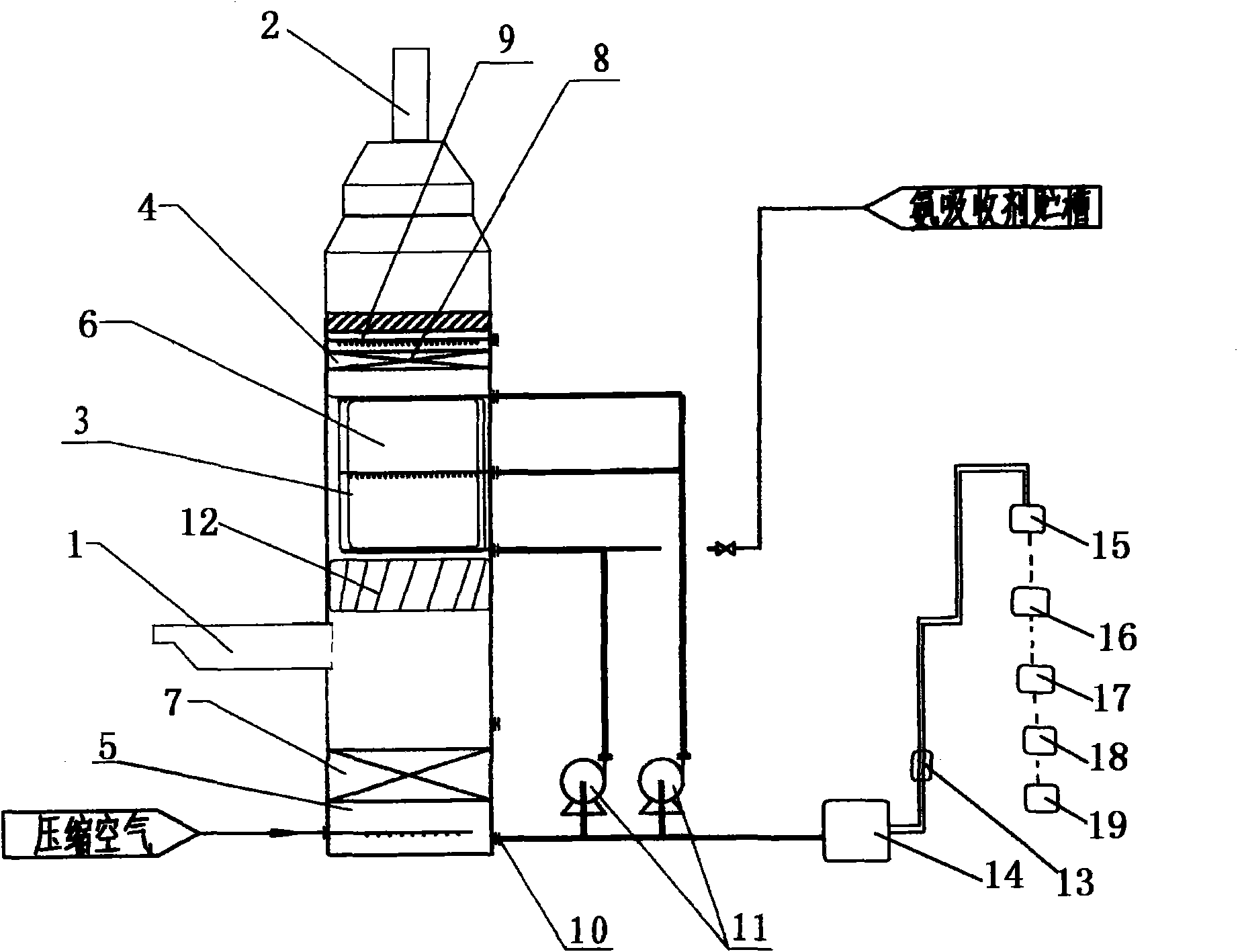

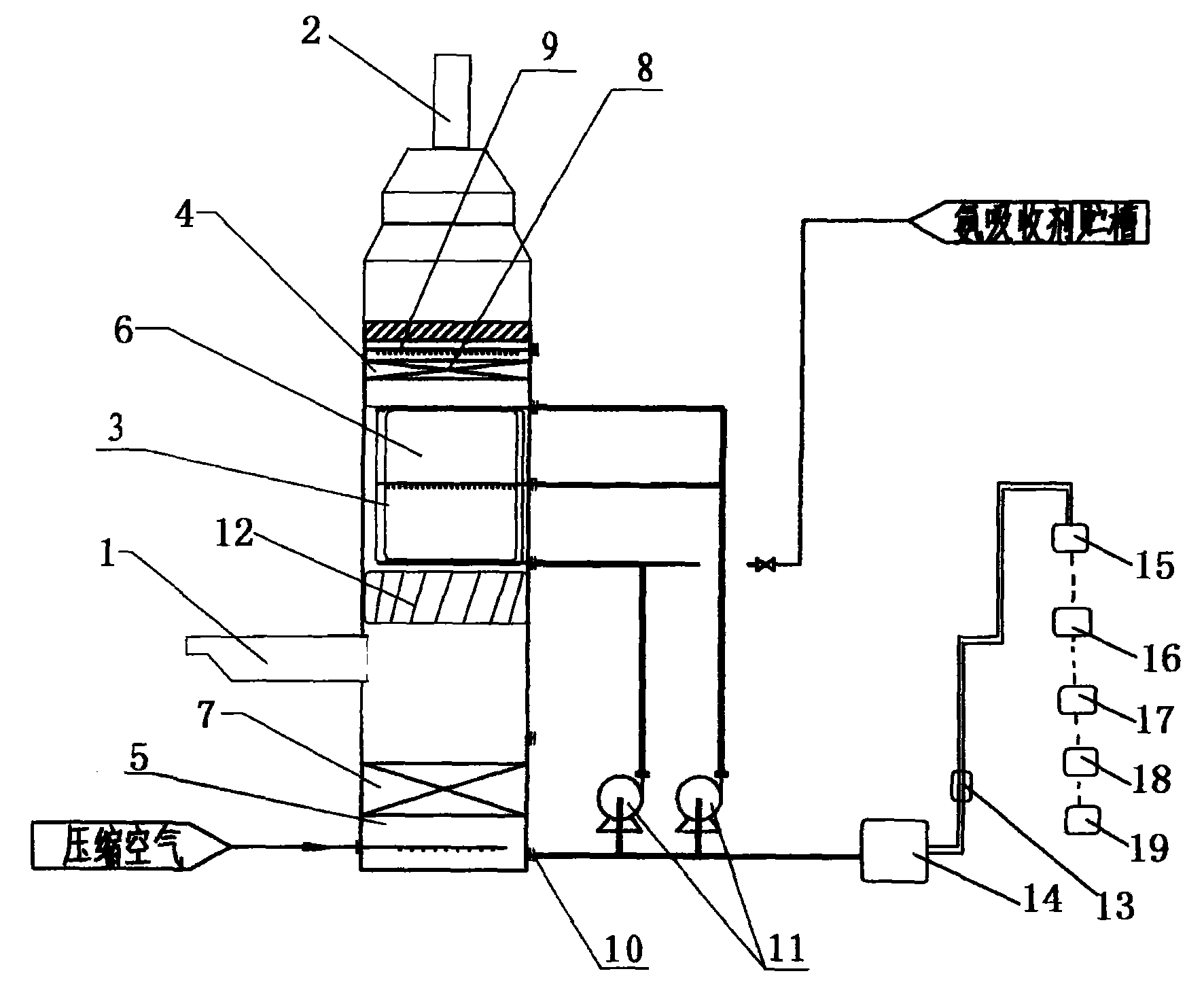

[0011] As shown in the figure, a double oxidation, double loop, double defogging and triple desulfurization tower and process equipment, the tower body is divided into 4 sections, from bottom to top are oxidation section 5, oxidation evaporation saturation section 7, purification and absorption Section 12, defogging section 4, a smoke inlet 1 is provided in the middle of the tower body, a smoke outlet 2 is provided at the top, a dehydration and defogging section 4 for removing water vapor is also provided, and a dehydration and defogging section 4 for collecting reaction products is provided at the bottom of the tower body The oxidation section 5 for ventilation and oxidation, the absorption spray section 3 is an empty tower structure without filler, a spray system 6 is set in this section, and the dehydration and defogging section 4 is provided with demist filler 8 and process water spray In the device 9, the oxidation section 5 is provided with a circulating liquid outlet 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com