Device and method for preparing sulfite

A technology of sulfite and acid sulfite, which is applied in the field of devices for preparing ammonium sulfite, ammonium sulfite, sodium metabisulfite and sodium sulfite, and can solve the problems of low purity of ammonium sulfite and ammonium sulfate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

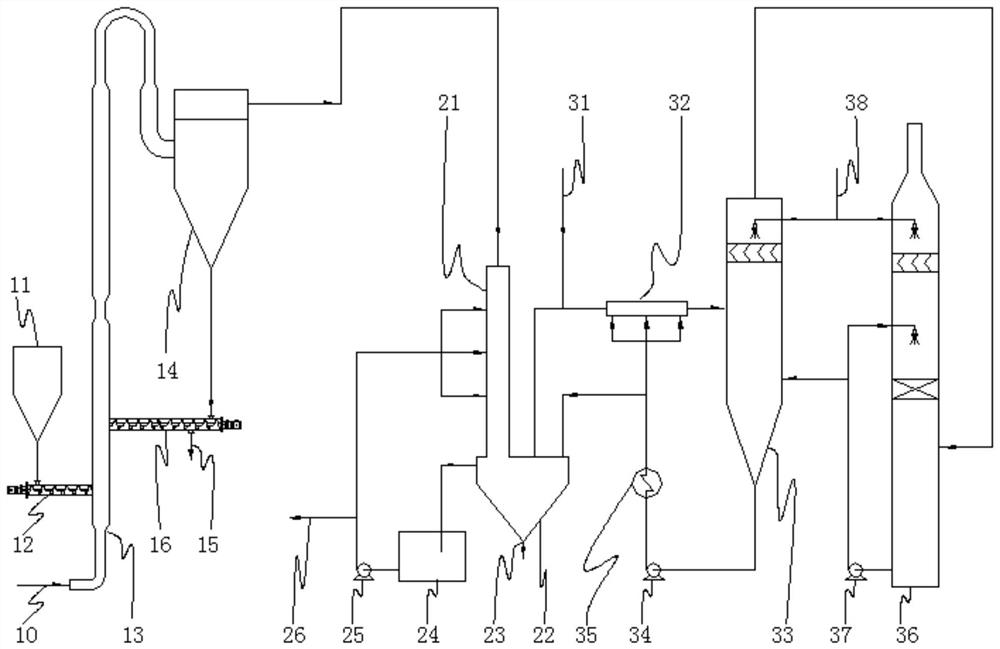

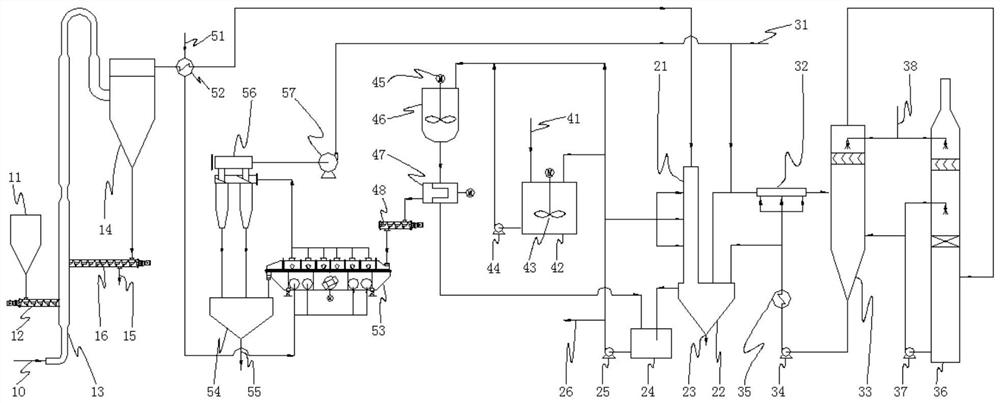

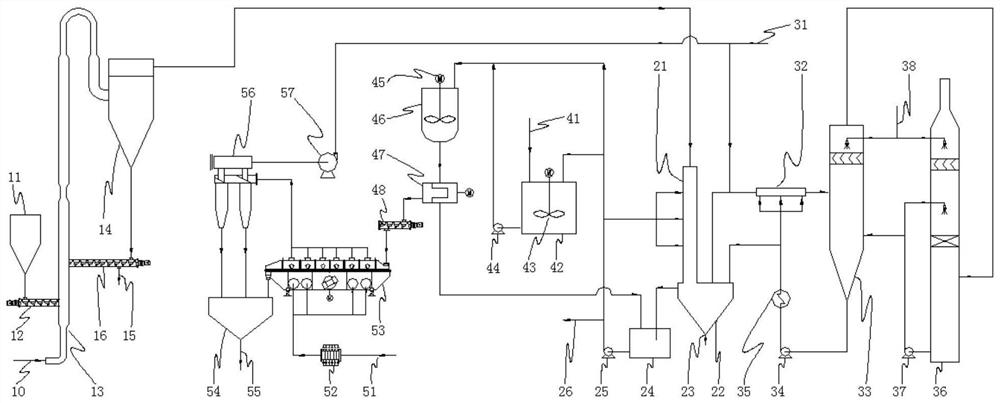

[0077] A kind of device for preparing sulfite The device is as follows:

[0078] Including five unit processes, including SO 2 After passing through the flue gas conditioning unit, the raw gas enters the acid sulfite preparation unit, the preparation of basic sulfite slurry and the residual SO 2 After the gas reabsorption unit is discharged out of the system, the synthesized intermediate slurry successively passes through the acid sulfite conditioning unit, the target product separation unit, and the product drying unit to finally obtain the solid phase target product or liquid phase target product.

[0079]The flue gas conditioning unit includes key node equipment and process flow such as a conditioning agent storage tank 11, a conditioning agent feeder 12, a flue gas conditioner 13, a dust collector 14, and a feeder 16; The preparation unit of acid sulfite includes key node equipment and process flow such as first-level re-spray pipe 21, first-level separation chamber 22, c...

Embodiment 2

[0089] Embodiment 2 ammonia method produces solid ammonium sulfite

[0090] S1 flue gas conditioning: In the flue gas conditioner, use the alkaline powder material from the conditioner feeder to absorb HF, HCl, SO3 and other components in the raw gas to generate solid particles, which are collected by the dust collector The flue gas that is intercepted and passed through the dust collector is the target gas. As the alkaline powder material, quicklime powder and slaked lime powder are selected and combined according to the ratio of the amount of substances (0.05-0.15): 1, and the median diameter of the powder is between 30-100 microns.

[0091] S2. Preparation of acid sulfite: The flue gas passing through the dust collector is in cross-flow contact with the absorbent in the primary re-nozzle to generate acid sulfite. When the pH value of the slurry in the primary separation chamber reaches 3.8-4.9 , corresponding to the relative density of the slurry is 1.18 ~ 1.20, the reacti...

Embodiment 3

[0098] Embodiment 3 ammonium bicarbonate method produces solid ammonium sulfite

[0099] S1, flue gas conditioning: the same as Example 2.

[0100] S2, preparation of acidic sulfite: same as example 2.

[0101] S3. Preparation of basic sulfite slurry: the residual gas not absorbed by the first-stage re-nozzle is further absorbed by the second-stage re-nozzle to generate basic sulfite slurry. Fresh absorbent comes from solid ammonium carbonate or bicarbonate outside the system.

[0102] Further, the pH value of the slurry in the secondary separation chamber is controlled from 5.1 to 10.0, and the preferred pH value control range is 5.6 to 8.0;

[0103] S4, residual SO 2 Reabsorption of gas: same as Example 2.

[0104] S5. Conditioning of acid sulfite: use liquid ammonia or ammonia water with a mass concentration of 15% to 33% to neutralize the slurry in the neutralization tank, and control the stirring rate at 26 to 43r / min. When the pH value reaches 7.3 After ~7.6, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com