Flue gas conditioning agent for flue gas mercury removal and composite flue gas purifying method thereof

A technology for flue gas purification and conditioning agent, applied in the field of flue gas purification, can solve the problems of high carbon content of fly ash, unsatisfactory mercury removal effect, influence on cement foaming rate, etc. Reuse value and avoid the effect of excessive carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

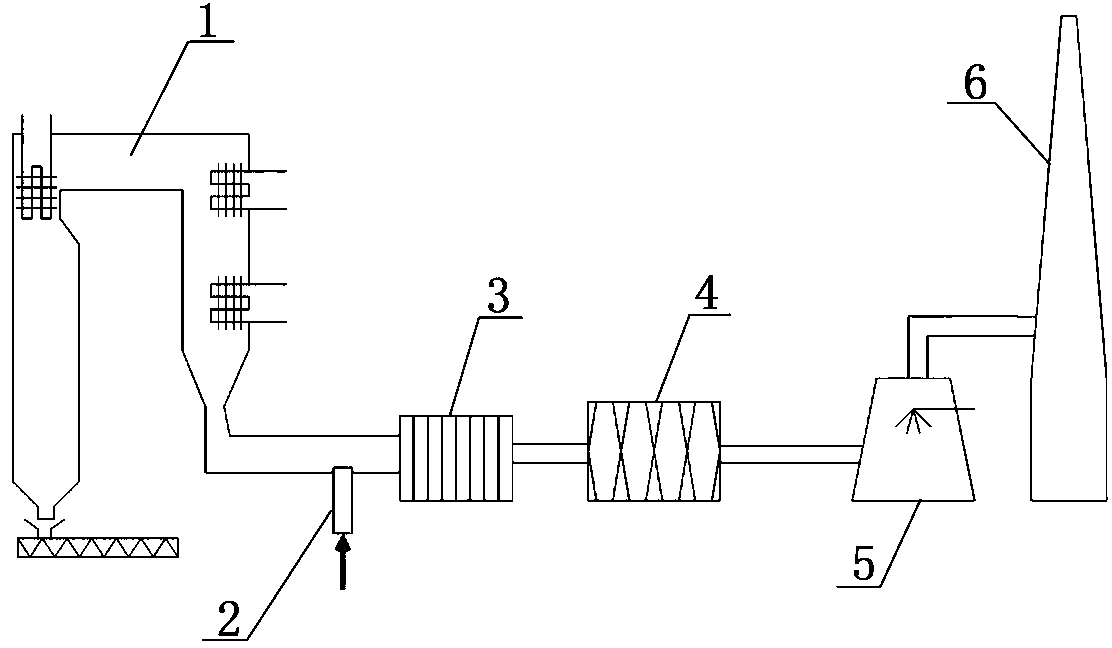

[0040] Embodiment one sees figure 1 As shown, in the flue gas system of a coal-fired power plant installed with SCR denitrification reactor 3, the fuel coal enters the burner 1 for combustion, releasing various flue gases including mercury (such as SO 2 , NO X , CO 2 etc.) and coal ash. After the high-temperature flue gas passes through various levels of steam heat exchangers and air preheaters, the flue gas is cooled below 450°C and then enters the SCR denitrification, dust collector 4 (electrostatic, cloth bag, or electric bag) for ash removal and wet desulfurization, purification The flue gas is finally exhausted into the atmosphere. In this embodiment, the flue gas conditioner is put into the flue at the entrance of the SCR denitrification reactor 3, and the conditioner can enter the flue through a separate delivery pipe, or enter the flue together with the ammonia used for denitrification. The smoke conditioner used can be liquid or solid. After the conditioning agen...

Embodiment 2

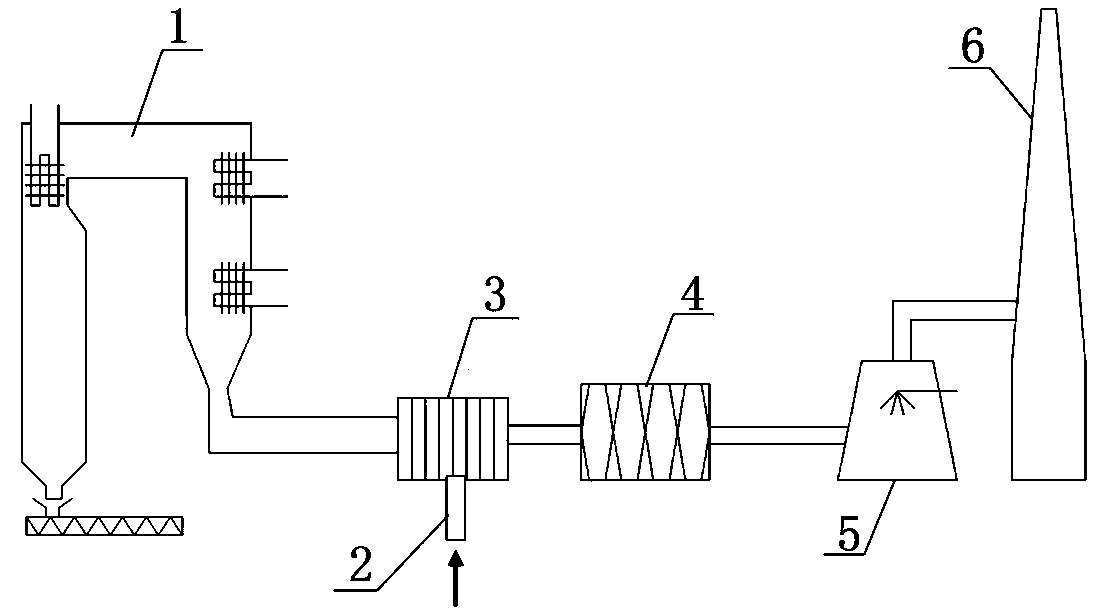

[0041] Embodiment two see figure 2 As shown, in the coal-fired power plant flue gas system installed with SCR denitrification reactor 3, in order to make full use of the oxidation and adsorption of gaseous mercury by flue gas conditioner and SCR catalyst, reduce or avoid unnecessary derivative The flue gas conditioner can also be directly placed in the middle or downstream of the SCR denitrification reactor 3 to enhance oxidation or adsorption of mercury and reduce the contact time between the flue gas conditioner / SCR catalyst and other flue gas components. The oxidized mercury and particulate mercury are mainly collected and removed by the desulfurization absorption tower and dust collector (electrostatic, cloth bag, or electric bag).

Embodiment 3

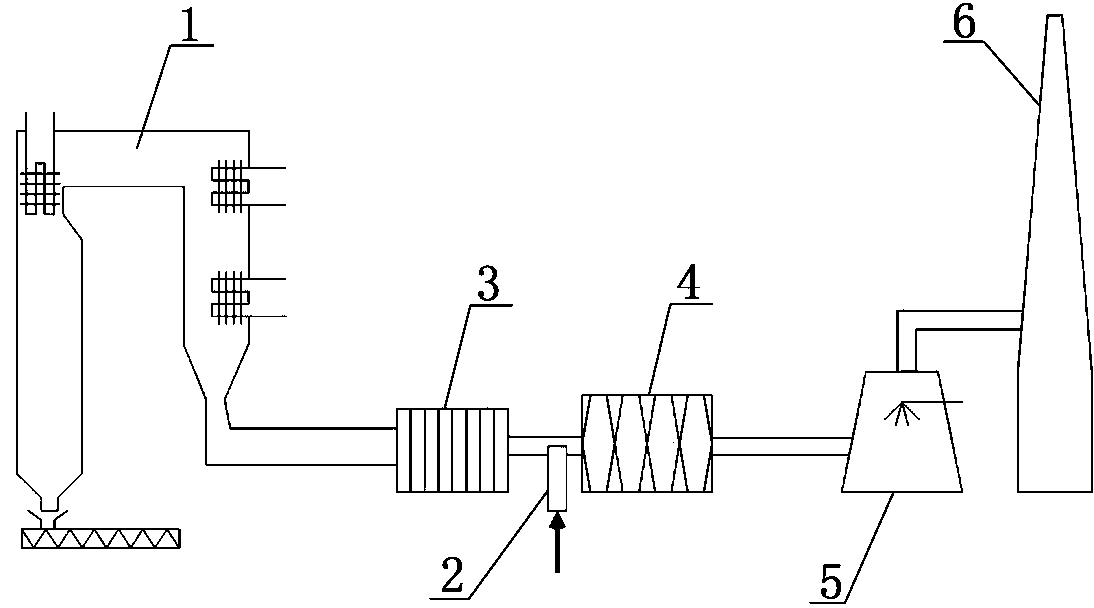

[0042] Embodiment three see image 3 As shown, in the flue gas system of a coal-fired power plant installed with SCR denitrification reactor 3, the flue gas conditioner is placed at the outlet of the SCR, and the flue gas demercury is implemented through the direct reaction of the flue gas conditioner itself with mercury vapor .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com