Ammonia-spillage amount control method in ammonia-process desulfurization

An ammonia desulfurization and ammonia release technology, which is applied in the fields of chemical engineering and environmental protection, can solve the problems of secondary environment corrosion of surrounding devices, increased ammonia consumption, and excess ammonia content, and is beneficial to environmental protection and improves utilization rate. , The effect of the amount of escaped ammonia reaching the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

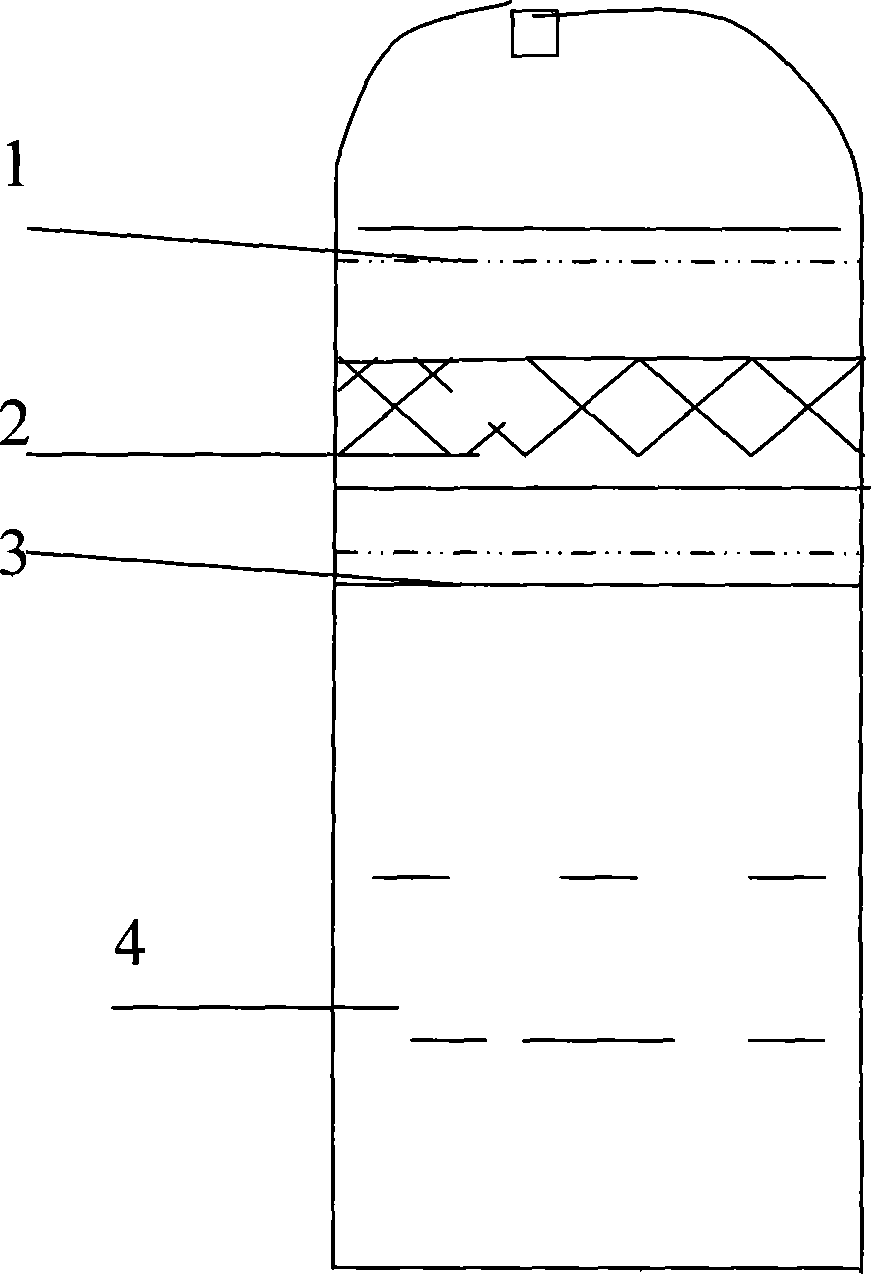

[0013] The invention adopts measures to strengthen the demisting of flue gas from the tower, that is, a self-developed baffle type high-efficiency flue gas desulfurization demister (2) and a demister (2) on the upper part of the washing and absorbing tower are arranged on the upper part of the traditional washing and absorbing tower. The process water flushing devices (1) and (3) facing the demister are arranged at the end. The sulfur-containing flue gas passes through the absorption section and undergoes neutralization reaction with the absorption liquid to form mist droplets. The mist droplets rise with the flue gas to the area of the demister (2), and the mist eliminator (2) collects the mist droplets. When the smoke containing mist flows through the channel of the demister (2), the impact and inertia of the mist, the centrifugal force of turning and the friction between it and the corrugated plate, and the adsorption make the mist trapped, and the demister ( 2) The multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com