Main transmission changeover mechanism in flat crushing flat auto dir cutting hot stamping machine

A conversion mechanism, flat and automatic technology, applied in printing presses, rotary printing presses, printing and other directions, to achieve the effect of simple structure, improved processing quality and production efficiency, and good economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

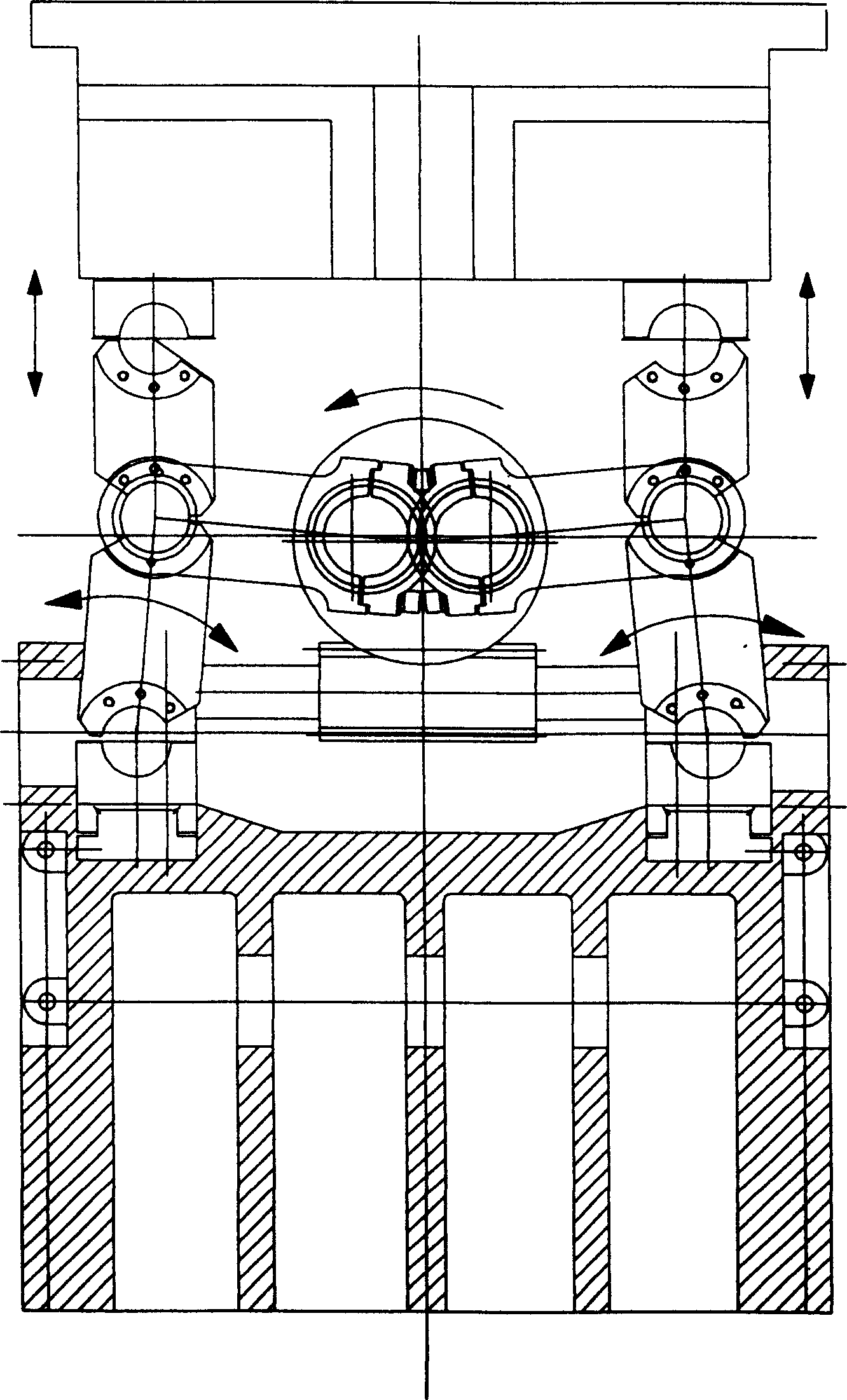

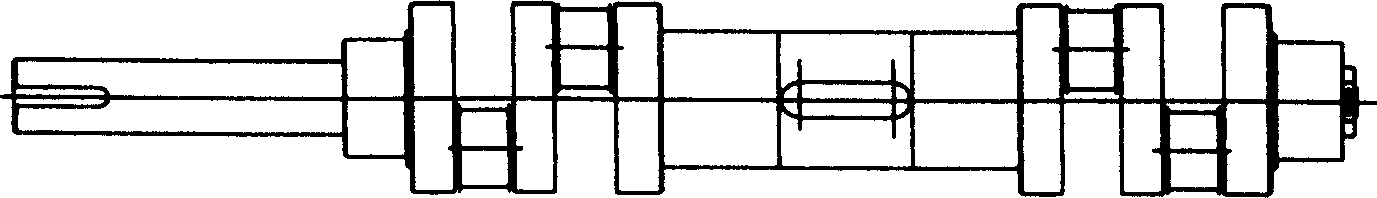

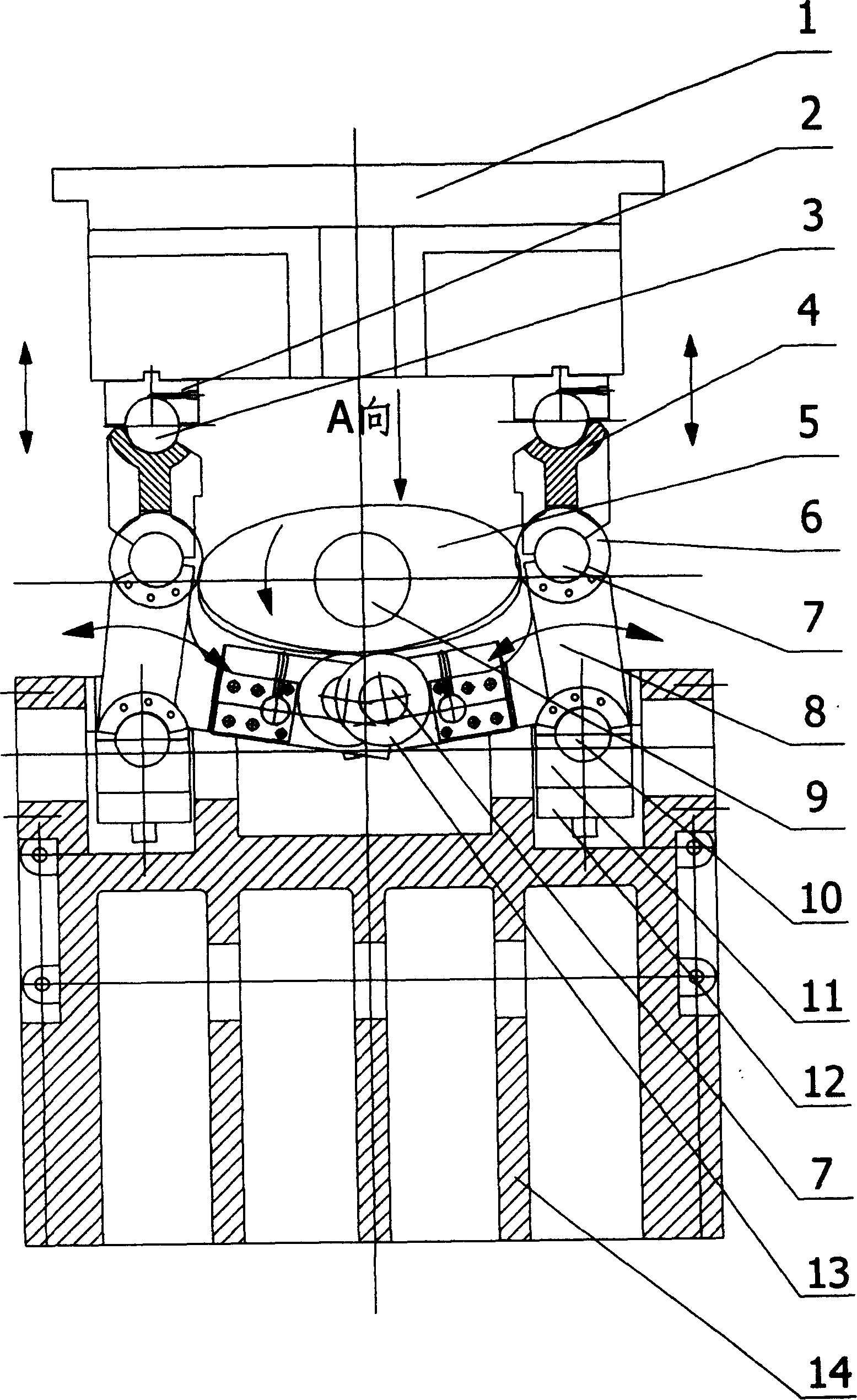

[0014] Embodiment: a kind of main transmission conversion mechanism in the automatic die-cutting hot stamping machine of flat pressing (see figure 2 , 3 ), comprising a machine base 14, a moving platform 1 and four groups of upper shaft seats 2 and toggle upper shafts 3 connected to the moving platform, and is characterized in that one or four groups of Conjugate cam group and four groups of lower toggle transmission mechanism, said four groups of conjugate cam group is composed of transmission shaft 9, four groups of conjugate cams 5a and 5b, and four groups of conjugate cams 5a and 5b are arranged according to the spacer 15 and the tension sleeve 16 are symmetrically assembled on the transmission shaft 9 in two groups, and each group of cams is composed of two cam discs 5a and 5b with different curvatures; The upper toggle lever 4 matched with the shaft 3, the toggle pivot 7, the right-angled lower toggle lever 8, the toggle lower axle 10, and the upper rollers 6 and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com