Solar energy-driven coal pyrolysis coupling coalite gasification reactor and method

A gasification reactor, solar energy technology, applied in the gasification process, granular/powder fuel gasification, energy input, etc., can solve the problems of difficulty in ensuring energy utilization efficiency, increasing the cost of oxygen, and low calorific value, etc. Improve the efficiency of energy utilization and conversion, increase the calorific value, and simplify the effect of the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

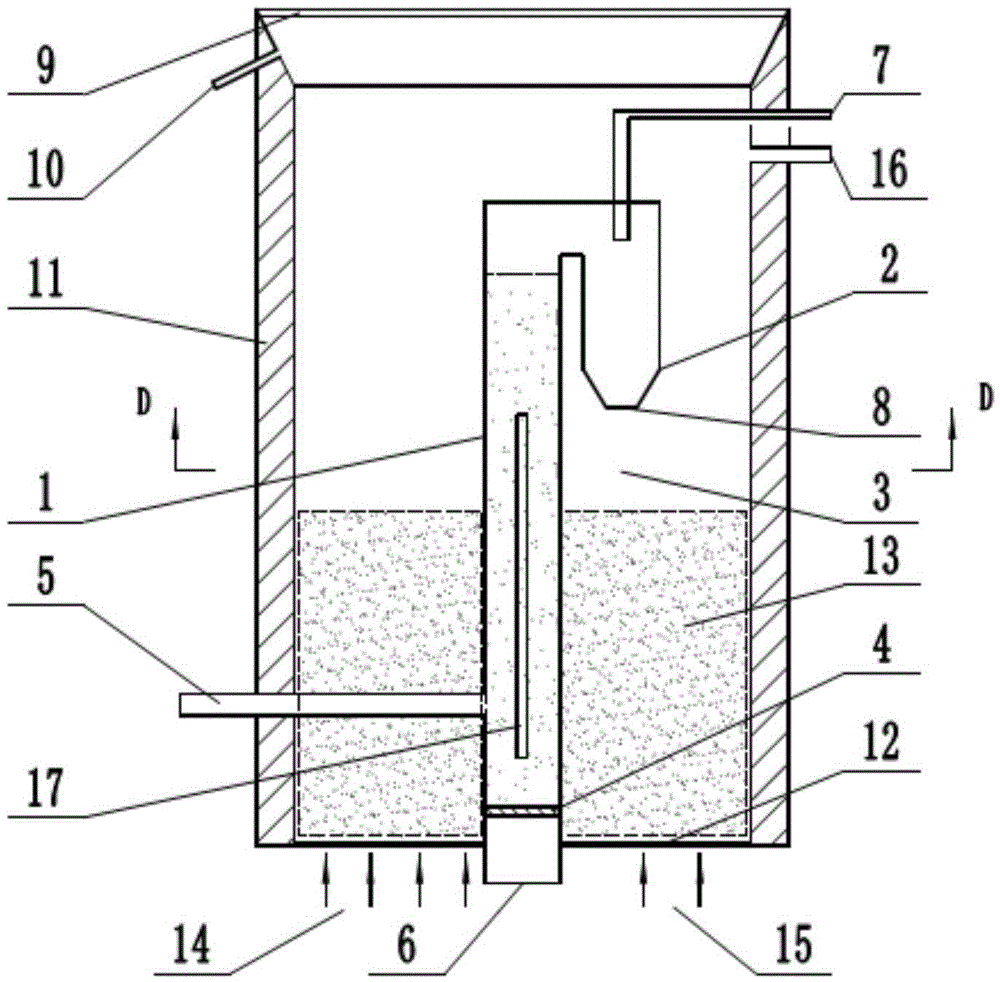

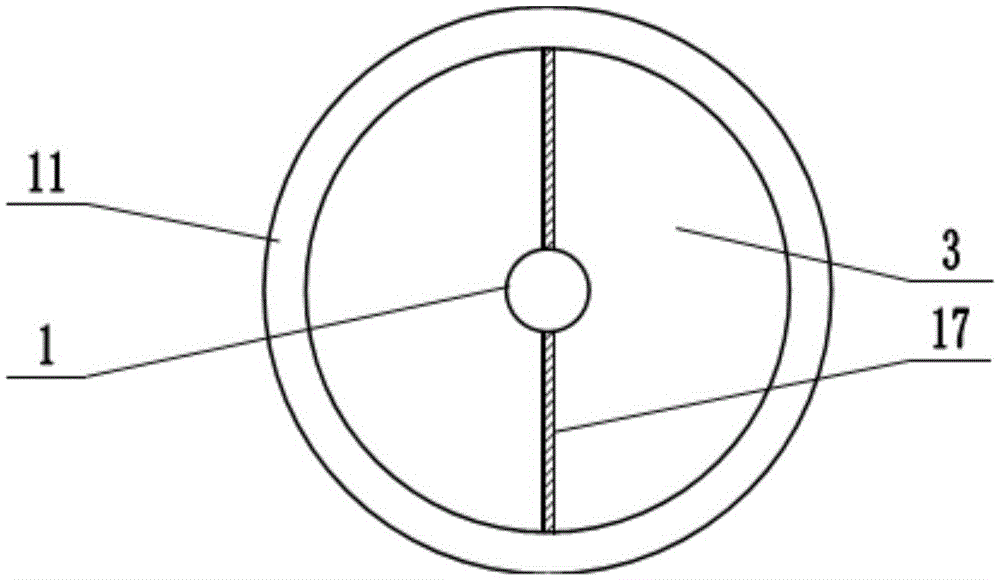

[0028] Such as figure 1 As shown, the present invention includes: a riser 1, a cyclone separator 2, an annular circulating fluidized bed 3, a riser air distribution plate 4, a coal supply pipe 5, a light-transmitting window 9, an insulating layer 11 and an annular air distribution plate 12. Wherein, a riser 1 is vertically arranged in the circulating fluidized bed 3 in the annular space, see figure 2 , the riser 1 is arranged at the center of the circulating fluidized bed 3 in the annulus, and the outer wall of the riser 1 is connected with the inner wall of the circulating fluidized bed 3 in the annulus through a baffle 17 . The upper end of the riser 1 is provided with a cyclone separator 2, and the riser 1 communicates with the cyclone separator 2, the cyclone separator 2 is arranged inside the circulating fluidized bed 3 in the annular space, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com