Method for recovering ammonia nitrogen in livestock and poultry breeding wastewater

A technology of livestock and poultry breeding wastewater and a recovery method, which is applied in the field of wastewater treatment, can solve the problems of unbalanced nutrient ratio, long start-up time, low load impact resistance, etc., so as to reduce suspended solids and heavy metals, reduce processing load and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

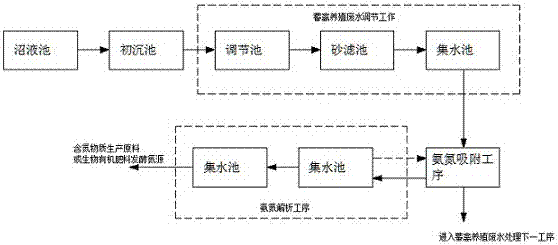

[0023] The recovery process of ammonia nitrogen in the livestock and poultry breeding wastewater in the embodiment is basically as attached figure 1 Shown:

[0024] Step a) Wastewater adjustment: feed the biogas slurry tank of livestock and poultry breeding wastewater into the primary sedimentation tank, and the standing time of the livestock and poultry breeding wastewater in the primary sedimentation tank is longer than 24H; then pass the static livestock and poultry breeding wastewater into the conditioning tank In the tank, add alkaline or acidic substances to the regulating tank, so that the pH value of the livestock and poultry breeding wastewater is between 8.2 and 8.6, and let the livestock and poultry breeding wastewater stand still in the regulating tank for 5H;

[0025]Step b) Filtration: Pass the upper layer of the livestock and poultry breeding wastewater in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com