Incineration disposal method for high-salinity wastewater

A treatment method and high-salt technology, which are applied in combustion methods, steam generation methods using heat carriers, incinerators, etc., can solve the problems of coking in incinerators, high salt content in flue gas, waste heat recovery devices and flue gas treatment equipment. Blockage and other problems, to avoid the effect of re-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

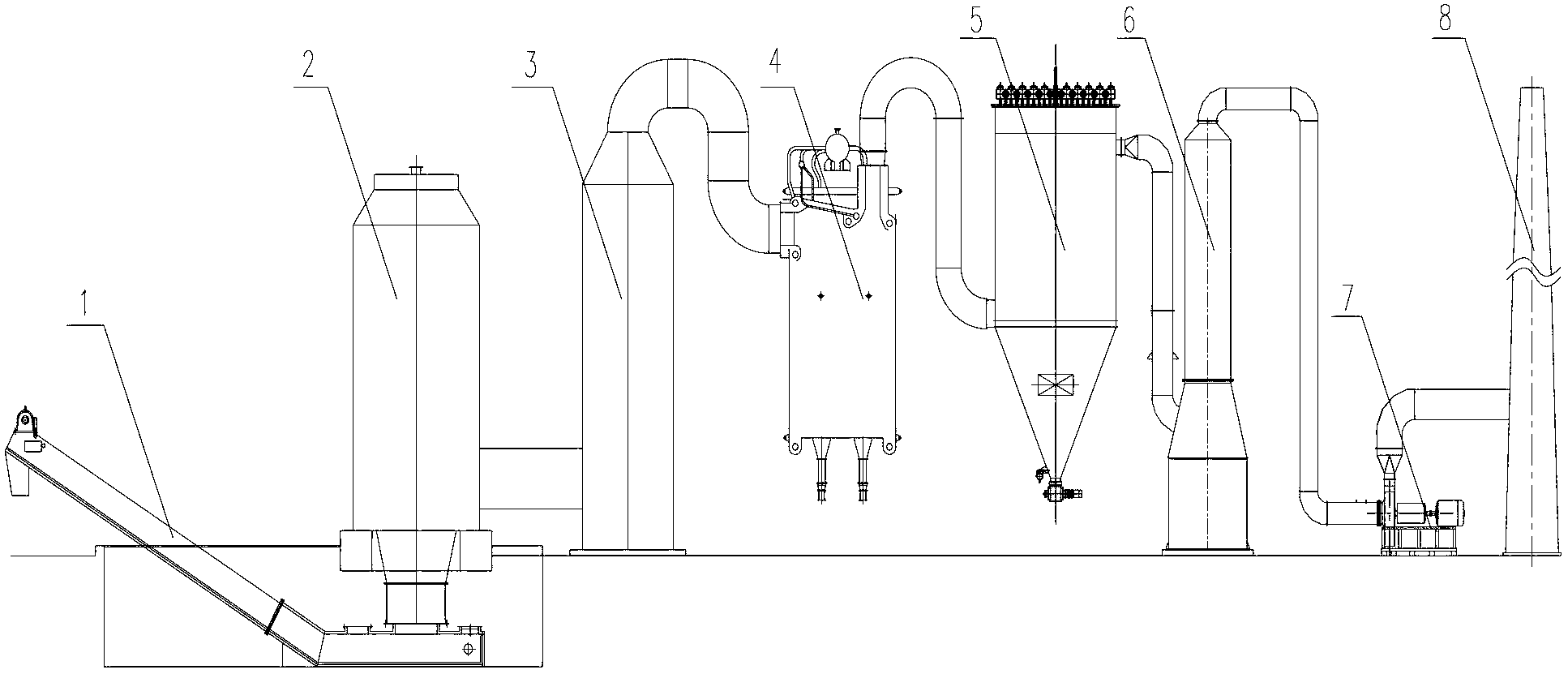

[0029] Such as figure 1 As shown, the main equipment of the high-salt wastewater incineration treatment method of the present invention includes: a combustion chamber 2, a combustion chamber 3, a dry slag remover 1, a waste heat boiler 4, a bag filter 5, a deacidification tower 6, an induction The fan 7 and the chimney 8 are communicated with each other through the flue, and the whole system maintains a slight negative pressure operation.

[0030] The steps of the present invention are as follows: high-salt waste liquid is sprayed into the first combustion chamber 2 after being atomized by compressed air through the spray gun arranged on the top of the first combustion chamber 2 . The first combustion chamber 2 is equipped with a light oil burner and an air supply system to maintain the temperature in the furnace at 600-700°C and fully evaporate the high-salt wastewater. The precipitated salt falls into the dry slag remover 1 located at the bottom of the first combustion cham...

Embodiment 2

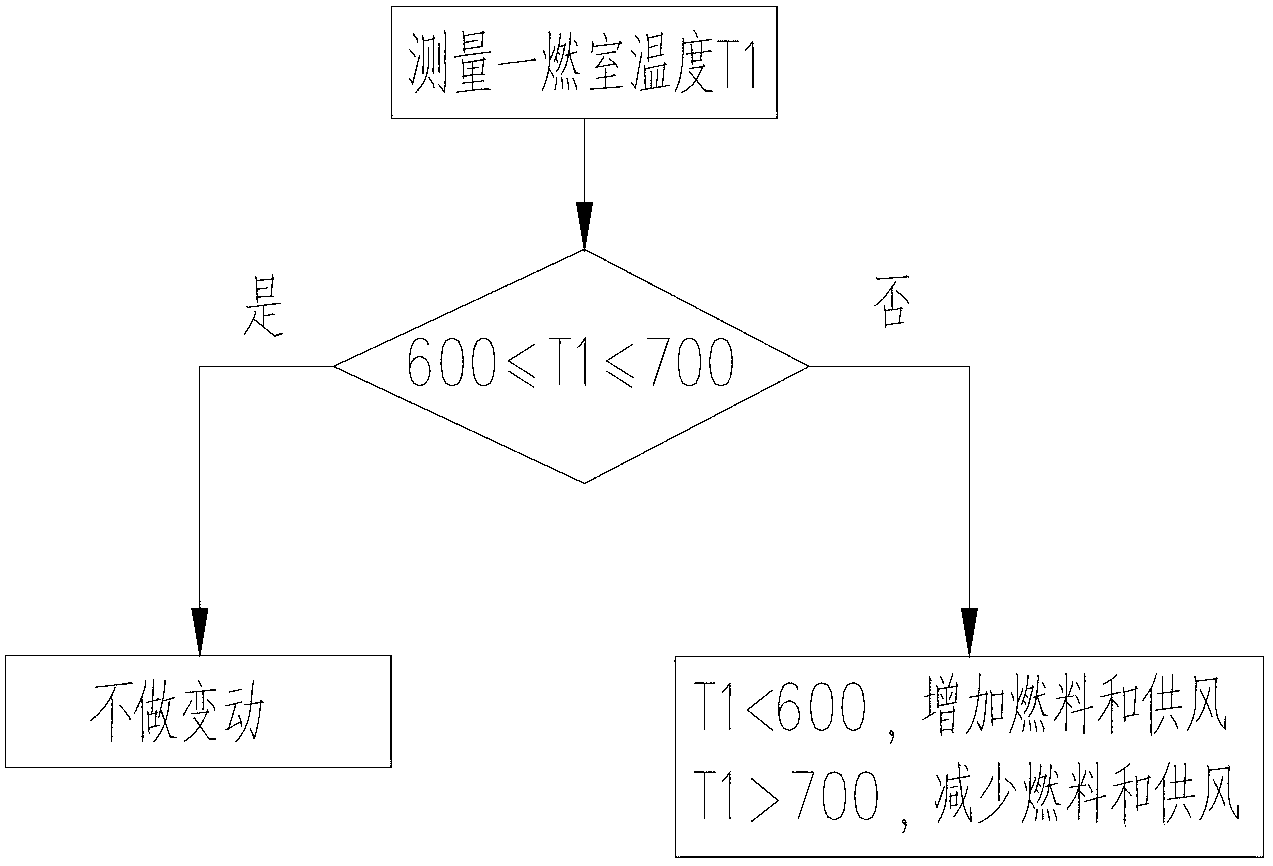

[0032] Such as figure 2 As shown, it is a schematic diagram of the control of two temperature conditions in the first combustion chamber. A temperature sensor is installed at the flue gas outlet of the first combustion chamber 2 to monitor the flue gas temperature T1 in the first combustion chamber 2 in real time, and the oil supply volume of the burner and the air supply volume of the fan are controlled by interlocking. When T1 is in the range of 600-700°C, the oil supply volume and air supply volume remain unchanged. When T1700°C, the temperature in the furnace is too high, and the salt in the high-salt wastewater may melt at high temperature. At this time, reduce the oil supply and air supply.

Embodiment 3

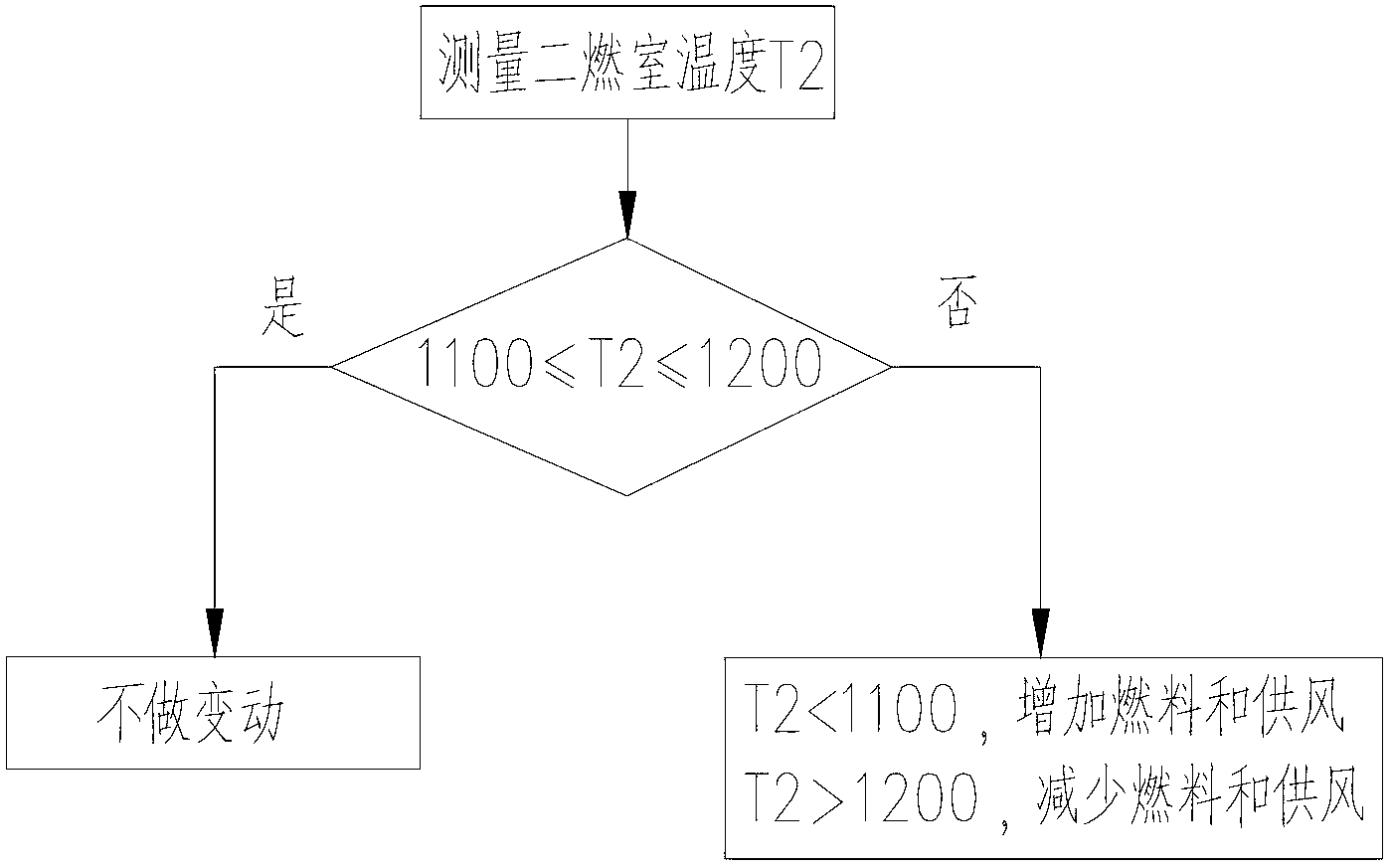

[0034] Such as image 3 Shown is a schematic diagram of temperature control in the second combustion chamber 3 . A temperature sensor is installed at the flue gas outlet of the second combustion chamber 3 to monitor the temperature T2 of the flue gas in the second combustion chamber 3 in real time, and the oil supply volume of the burner and the air supply volume of the fan are controlled by interlocking. When T2 is in the range of 1100-1200°C, the oil supply volume and air supply volume remain unchanged. When T21200°C, the temperature in the furnace is too high, there is a risk of increasing nitrogen oxides in the flue gas, and the economy is poor. At this time, reduce the oil supply and air supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com