Oil, water and solid multi-phase separation method for natural gas

A multi-phase separation, natural gas oil technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of shortened operating life of coalescing filter elements, difficult operation and management, inconvenient maintenance, etc., and achieve compact structure , less space required and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

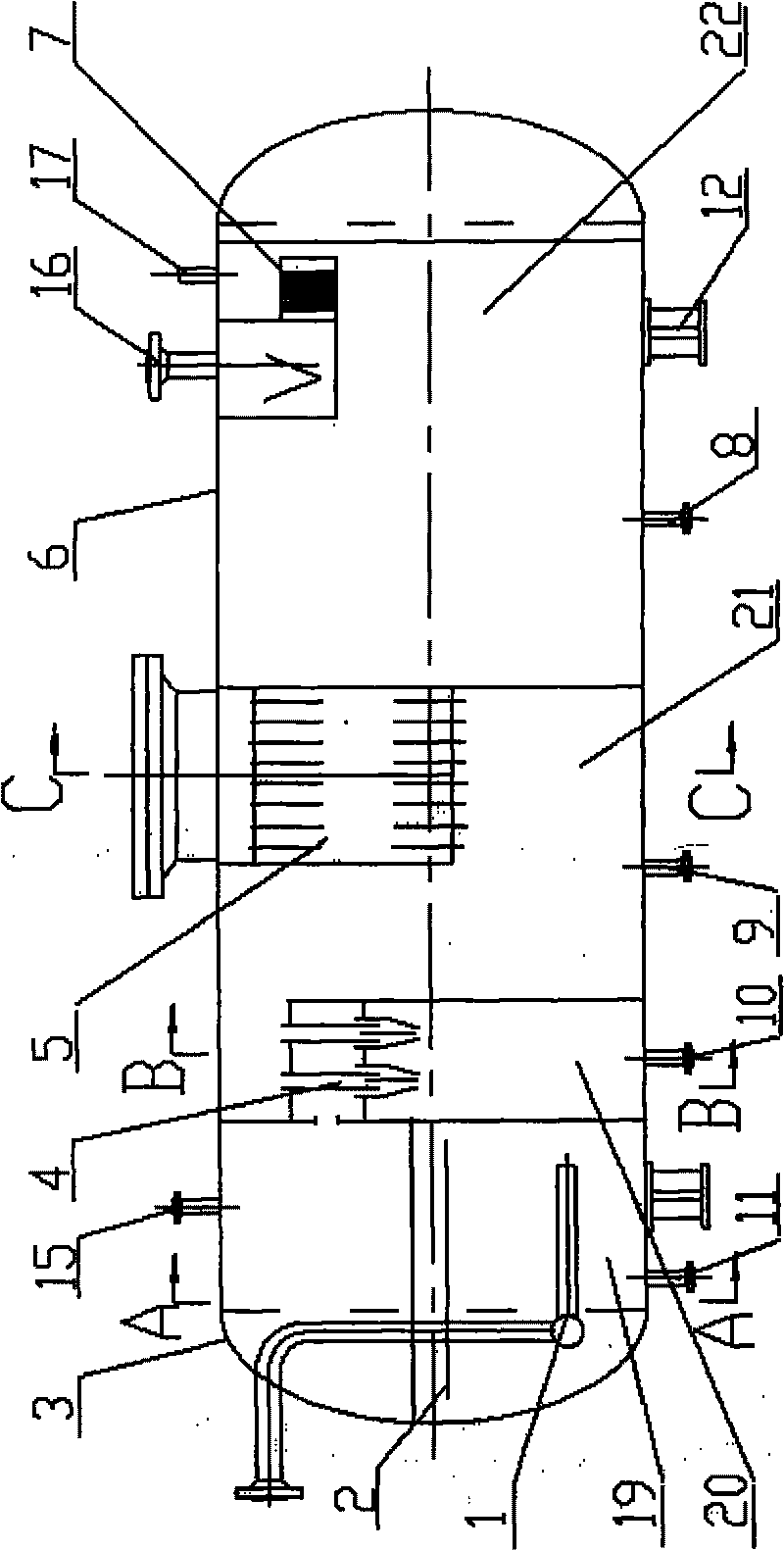

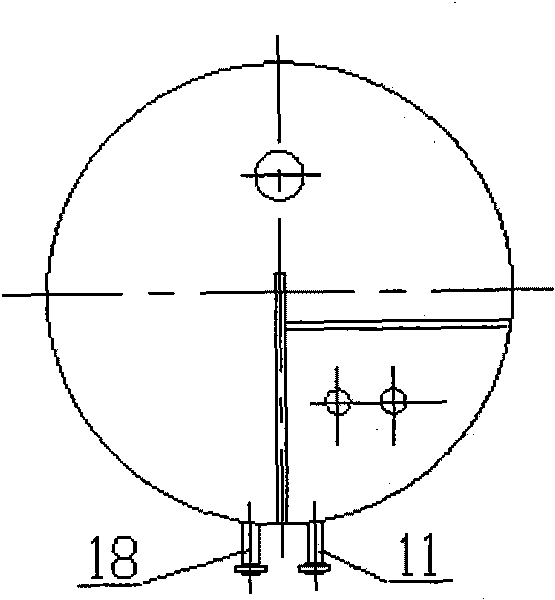

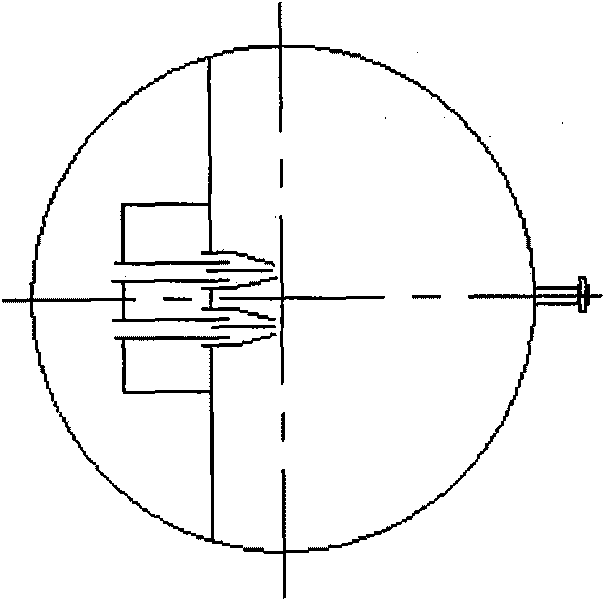

[0023] Such as figure 1 As shown, the equipment shell includes the left and right heads 3, the cylinder body 6 and the support 12. The left and right heads 3 seal and connect the left and right ends of the cylinder body 6 to form a horizontal tank structure. The horizontal tank body is divided into four areas, respectively It is the air intake water washing area 19, the cyclone separation area 20, the coalescence separation area 21, and the terminal mist trapping area 22. Through the four areas, the air intake → water washing → cyclone separation → oil and water coalescence → (gravity sedimentation) → Terminal mist capture → gas outlet (exported) natural gas oil, water, solid multi-phase separation process.

[0024] There is a gas redistribution plate 2 in the inlet water washing area 19. The fluid produced by the gas well passes through the wellhead and the gas collection process, and after being heated by the heating furnace, it enters the water washing section through the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com