Method for preparing low temperature green antique glaze by utilizing iron-ore slag

A technology of iron ore slag and low temperature, applied in the field of material science, can solve the problems of energy saving and emission reduction, complex process, high cost, etc., and achieve the effect of reusing waste, high gloss and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

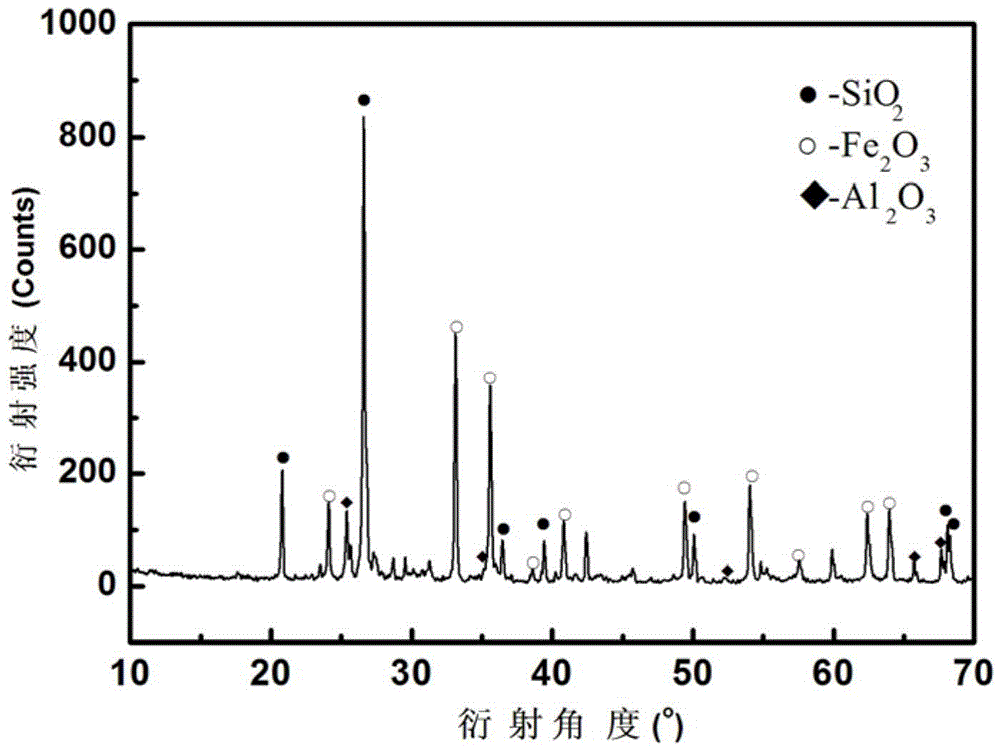

Image

Examples

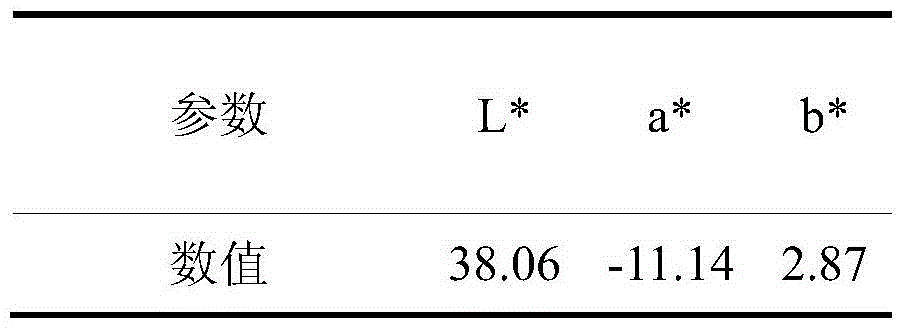

Embodiment 1

[0019] 1) Preparation of ultra-fine slag: After coarsely grind the iron slag with a vibrating mill to pass through an 80-mesh sieve, grind it evenly in a mortar, put it in a high-energy ball mill, and ball mill it at a speed of 1400r / min for 70 minutes After taking it out, it is passed through a 200-mesh sieve to obtain superfine slag.

[0020] 2) Preparation of clinker containing slag: In terms of mass percentage, combine 13% feldspar, 27% borax, 8% potassium carbonate, 3% sodium carbonate, 5% limestone, 8% barium carbonate, 33% zirconium silicate and 3% boric acid are mixed uniformly to obtain a mixture. Add superfine slag accounting for 8% of the mass of the mixture to the mixture and mix it evenly by ball milling. Pass a 200 mesh sieve to remove the sieve and put the sieve into the oxidation In an aluminum crucible, the temperature is kept at 1250°C for 40 minutes for melting, and a low-temperature frit is obtained after water quenching.

[0021] Wherein, the ball milling is p...

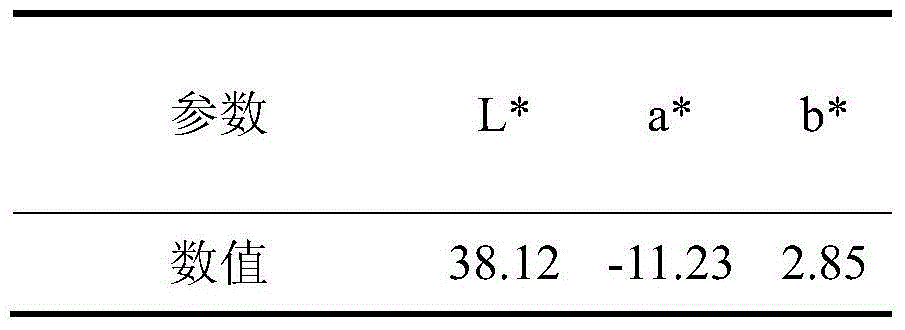

Embodiment 2

[0029] 1) Preparation of ultra-fine slag: After coarsely grind the iron slag with a vibrating mill to pass an 80-mesh sieve, grind it evenly in a mortar, put it in a high-energy ball mill, and ball mill it at a speed of 1500r / min for 60 minutes. After taking it out, it is passed through a 200-mesh sieve to obtain superfine slag.

[0030] 2) Preparation of clinker containing slag: In terms of mass percentage, 14% feldspar, 24% borax, 9% potassium carbonate, 2% sodium carbonate, 4% limestone, 9% barium carbonate, 34% zirconium silicate and 4% boric acid are mixed uniformly to obtain a mixture. Add superfine slag, which accounts for 10% of the mass of the mixture, and mix it evenly by ball milling. Pass a 200-mesh sieve to remove the sieve and put the sieve into the oxidation In an aluminum crucible, the temperature is kept at 1300°C for 30 minutes for melting, and a low-temperature frit is obtained after water quenching.

[0031] Wherein, the rotating speed of the ball mill used in ...

Embodiment 3

[0039] 1) Preparation of ultra-fine slag: After coarsely grind the iron slag with a vibration mill to pass a 60-mesh sieve, grind it evenly in a mortar, put it into a high-energy ball mill, and mill it at a speed of 1500r / min for 70 minutes. After taking it out, it is passed through a 250-mesh sieve to obtain superfine slag.

[0040] 2) Preparation of clinker containing slag: In terms of mass percentage, 15% feldspar, 26% borax, 10% potassium carbonate, 1% sodium carbonate, 3% limestone, 7% barium carbonate, 36% zirconium silicate and 2% boric acid uniformly obtain the mixture. Add 11% of the mass of the mixture to the mixture with ultra-fine slag and ball mill to mix evenly. Pass the 250-mesh sieve to remove the sieve, and put the sieve into the alumina In the crucible, the temperature is kept at 1350°C for 30 minutes for melting, and the low temperature frit is obtained after water quenching.

[0041] Wherein, the ball milling is performed in a ball mill, and the rotation speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com