A kind of self-sintering fireproof polystyrene insulation material and preparation method thereof

An insulation material and self-fusing technology, applied in the field of building wall insulation materials, can solve the problems of flammability, high fire hazards, narrowing the scope of use, etc., and achieve the effects of long life, good fire performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of a kind of self-sintering fireproof polystyrene insulation material of the present invention comprises the following steps:

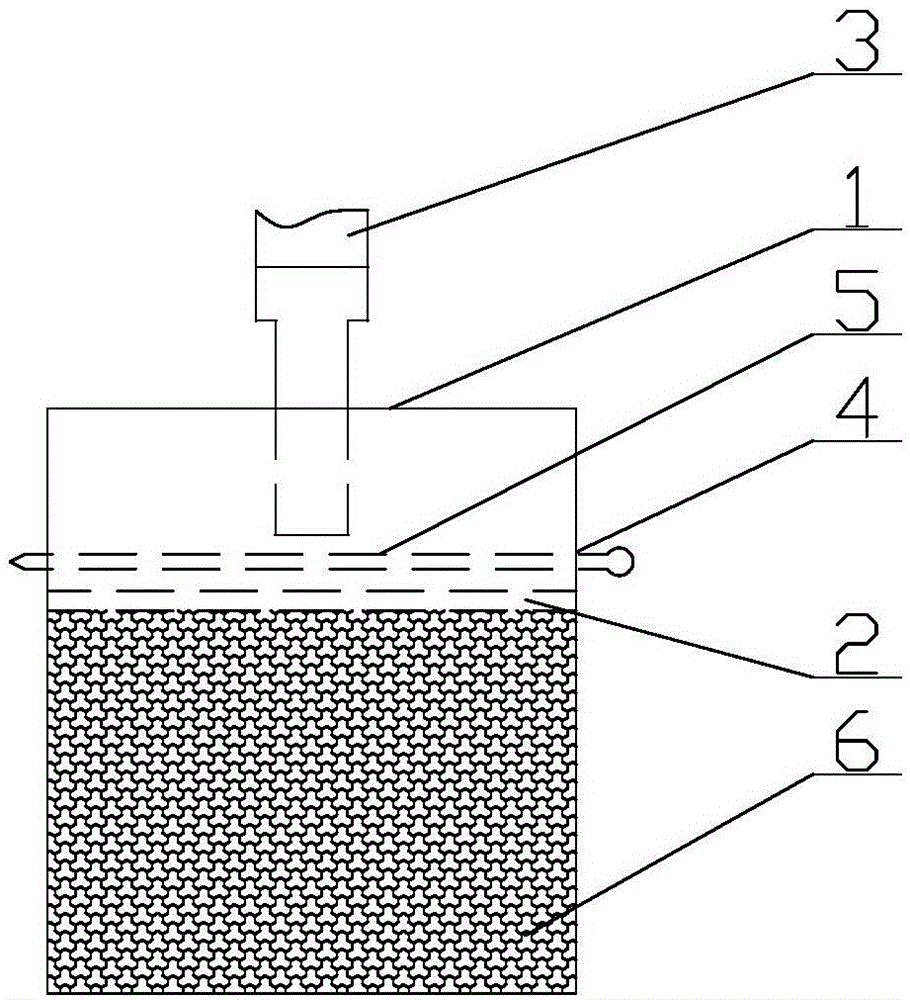

[0032] 1) Calculate the diameter of polystyrene particles as 3mm, and prepare the mold according to the compression ratio of 1:1.5. The mold is composed of mold box 1, pressure plate 2 and bolt rod 5, and the limit hole 4 for passing through bolt rod 5 is set on mold box 1 ;(See figure 1 )

[0033] 2) Magnesium oxychloride cement and water according to the weight ratio of water-cement ratio 0.6-0.7:1, and additional coagulant is added according to the proportion, first put the powder and then water, put it into the mixer and stir evenly to make active magnesium oxychloride cement slurry gelling agent spare;

[0034] 3) Put the polystyrene EPS foam particles and waste benzene particles weighed according to the proportion into the mixing mixer, slowly add the magnesium oxychloride cement slurry gelling agent according to ...

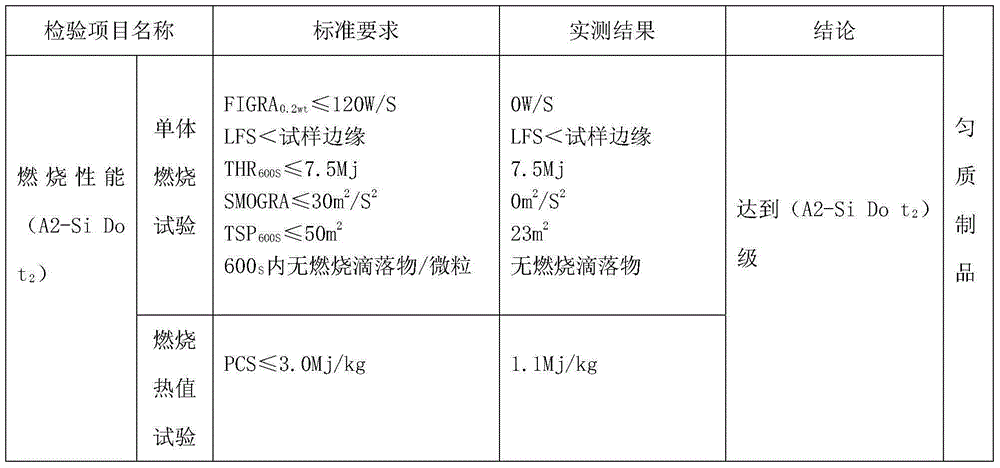

Embodiment 1

[0041] [Example 1] A self-sintering fireproof polystyrene insulation material and its preparation process

[0042] The weight ratio of each component of this material is:

[0043] 3 parts of polystyrene EPS foam particles

[0044] 1 part of waste benzene pellets

[0045] 24 parts of magnesium oxychloride cement slurry gelling agent.

[0046] Magnesium oxychloride cement slurry gelling agent is composed of magnesium oxychloride cement and coagulant in a weight ratio of 1:0.05; the composition and weight ratio of magnesium oxychloride cement is MgO:MgCl 2 :H 2 O=3:1:11; the present embodiment adopts active magnesia (MgO) produced in Haicheng, Liaoning and magnesium chloride hexahydrate (MgCl) produced in Dalian. 2· 6H 2 O); the coagulant is MgSO 4 and sulfocrown ether, added at a weight ratio of 1:0.05;

[0047] In this embodiment, the preparation process of self-sintering fireproof polystyrene insulation material is as follows:

[0048] 1) Calculate the diameter of poly...

Embodiment 2

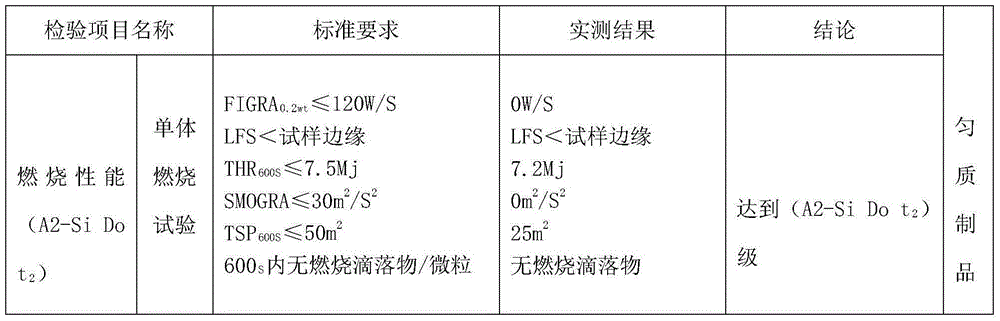

[0056] [Example 2] A self-sintering fireproof polystyrene insulation material and its preparation process

[0057] The weight ratio of each component of this material is:

[0058] 2 parts of polystyrene EPS foam particles

[0059] 0.5 parts of waste benzene pellets

[0060] 15 parts of magnesium oxychloride cement slurry gelling agent.

[0061] Magnesium oxychloride cement slurry gelling agent is composed of magnesium oxychloride cement and coagulant in a weight ratio of 1:0.02; the composition and weight ratio of magnesium oxychloride cement is MgO:MgCl 2 :H 2 O=3:1:11; the present embodiment adopts active magnesia (MgO) produced in Haicheng, Liaoning and magnesium chloride hexahydrate (MgCl) produced in Dalian. 2· 6H 2 O); the coagulant is MgSO 4 and sulfocrown ether, added at a weight ratio of 1:0.05;

[0062] In this embodiment, the preparation process of self-sintering fireproof polystyrene insulation material is as follows:

[0063] 1) Calculate the diameter of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com