Pressure regulator static characteristic detection system

A detection system and pressure regulator technology, applied in instruments, measuring devices, measuring fluid pressure, etc., can solve problems such as difficult fine-tuning, difficult data accuracy, waste of air source, etc., to achieve easy observation and operation, accurate performance data, and airflow. The effect of pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

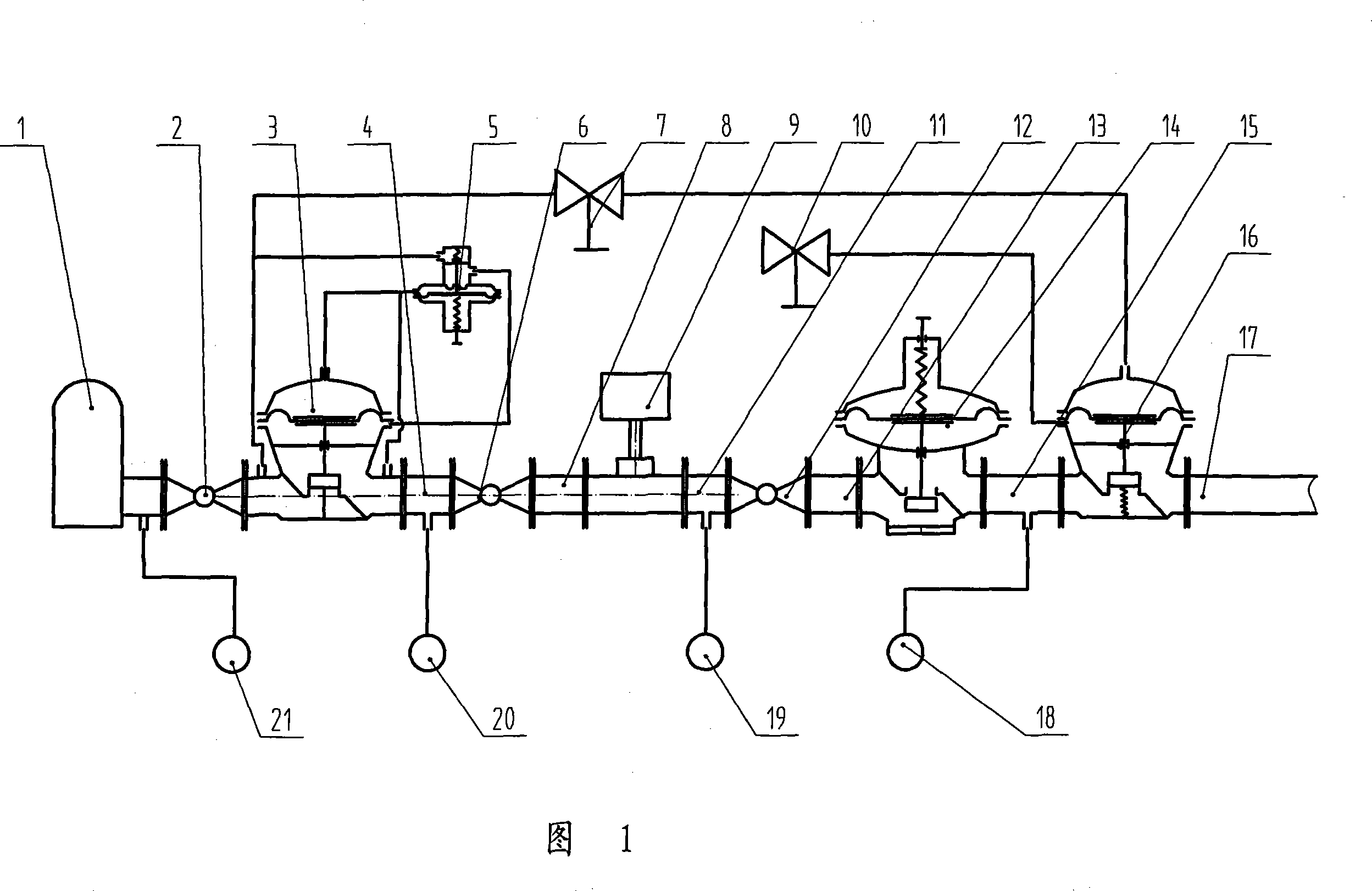

[0012] The static characteristic detection system of the pressure regulator is composed of a gas storage tank (1), a ball valve (2), a primary pneumatic valve (3), a pipeline (4), a ball valve (6), a pipeline (8), a turbine flowmeter (9) , pipeline (11), ball valve (12), pipeline (13), tested pressure regulator (14), pipeline (15), secondary pneumatic valve (16), exhaust pipeline (17) are connected with bolts in sequence made. The primary pneumatic valve (3) is composed of a main body and a pilot (5), which are connected by a signal tube and a quick connector. The secondary pneumatic valve (16) consists of a main body, a needle valve (7) and an exhaust valve (10), which are connected with a signal pipe and a quick connector. A pressure gauge (18), ( 19), (20), (21), each pressure gauge (18), (19), (20), (21), the first-stage pneumatic valve pilot (5), the needle shape of the second-stage pneumatic valve (16) The valve (7) and the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com