Novel crude oil emulsion electrostatic dehydrator

An electrostatic dehydration and emulsion technology, applied in the direction of electric/magnetic dehydration/emulsification, etc., can solve the problems that are not conducive to the high efficiency, miniaturization, reduction of dehydration efficiency, and increase of water droplet settlement time, etc., so as to improve safety Performance and stability, reduced energy consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

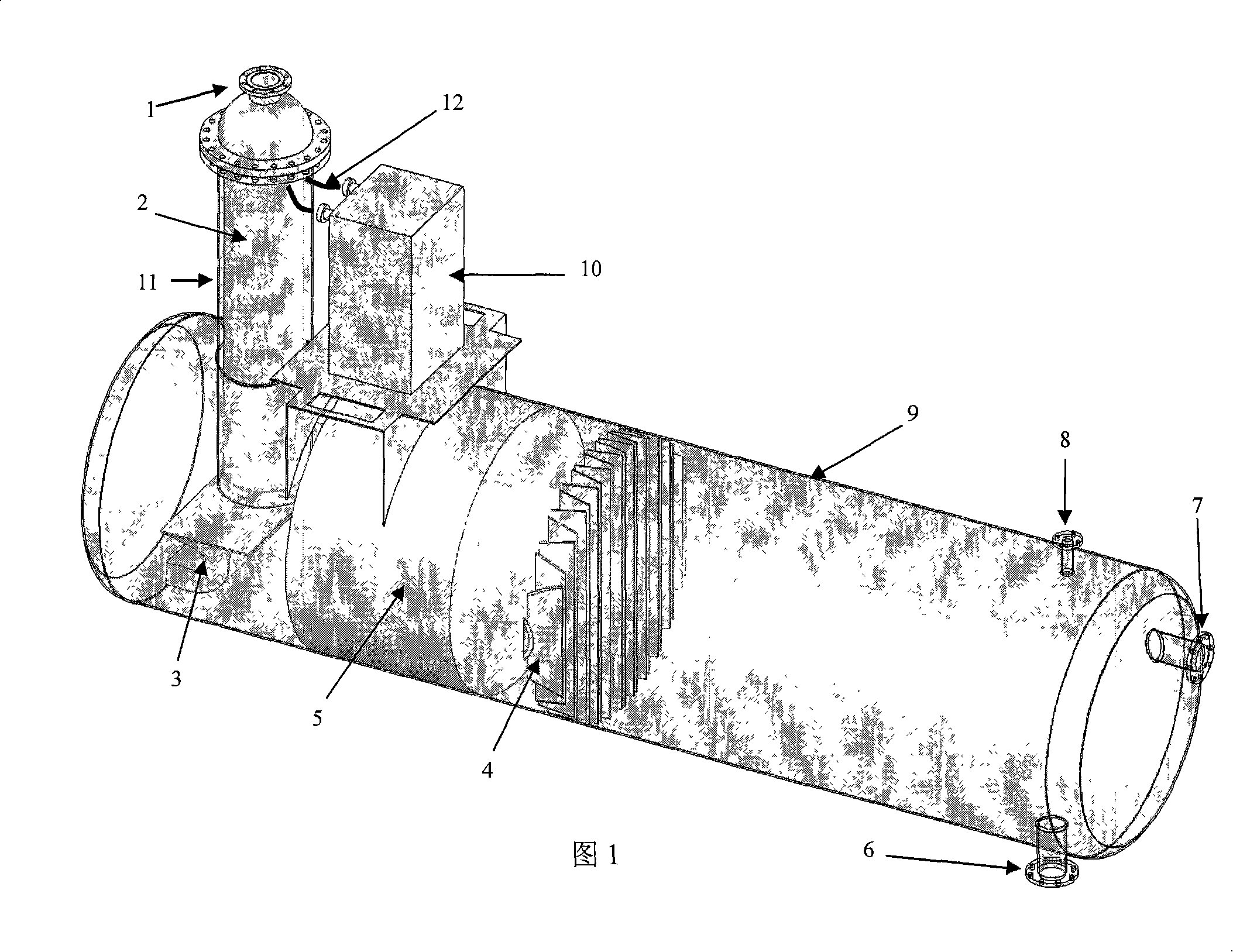

[0029] The technical characterictic of the present invention will be described in detail below in conjunction with accompanying drawing:

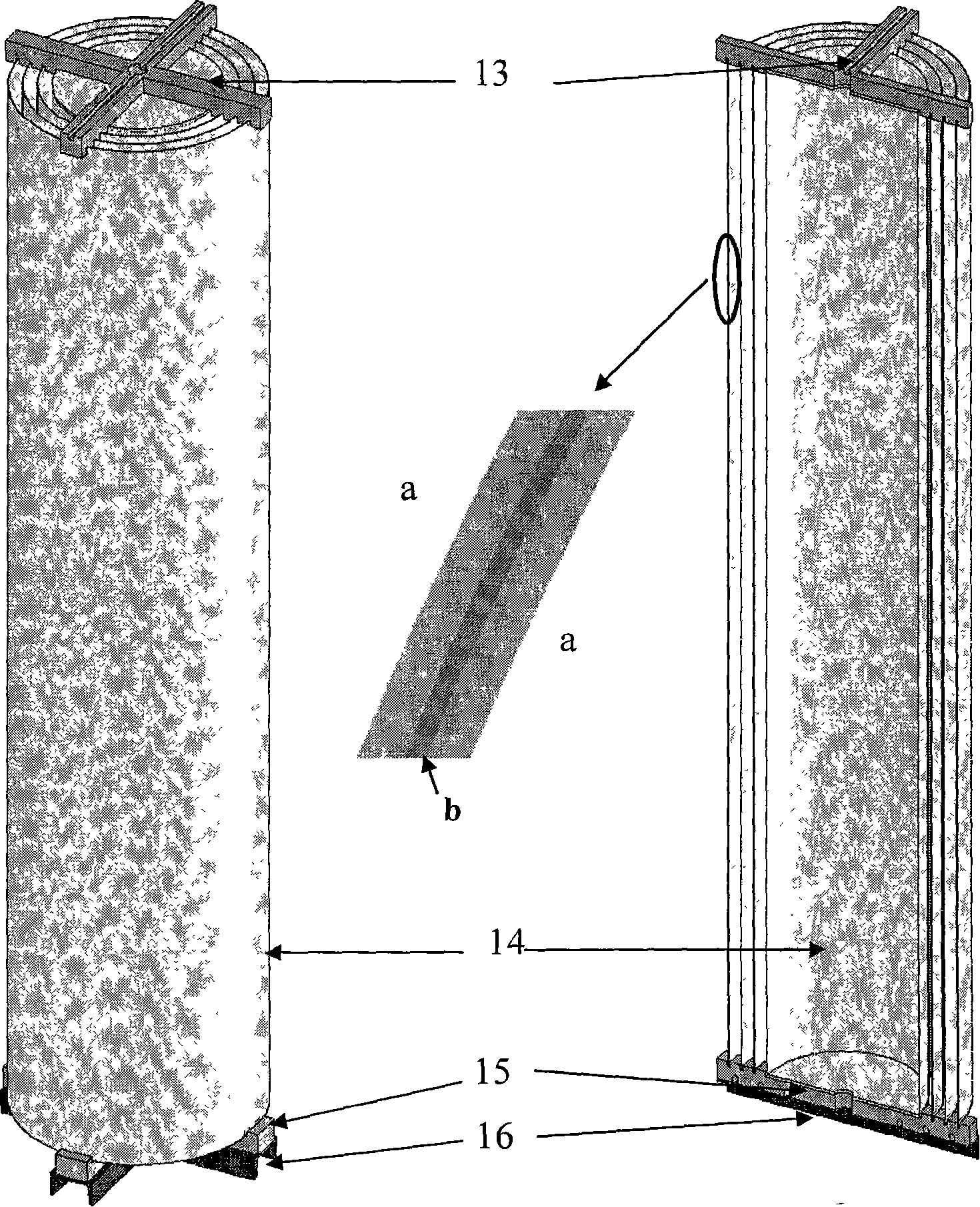

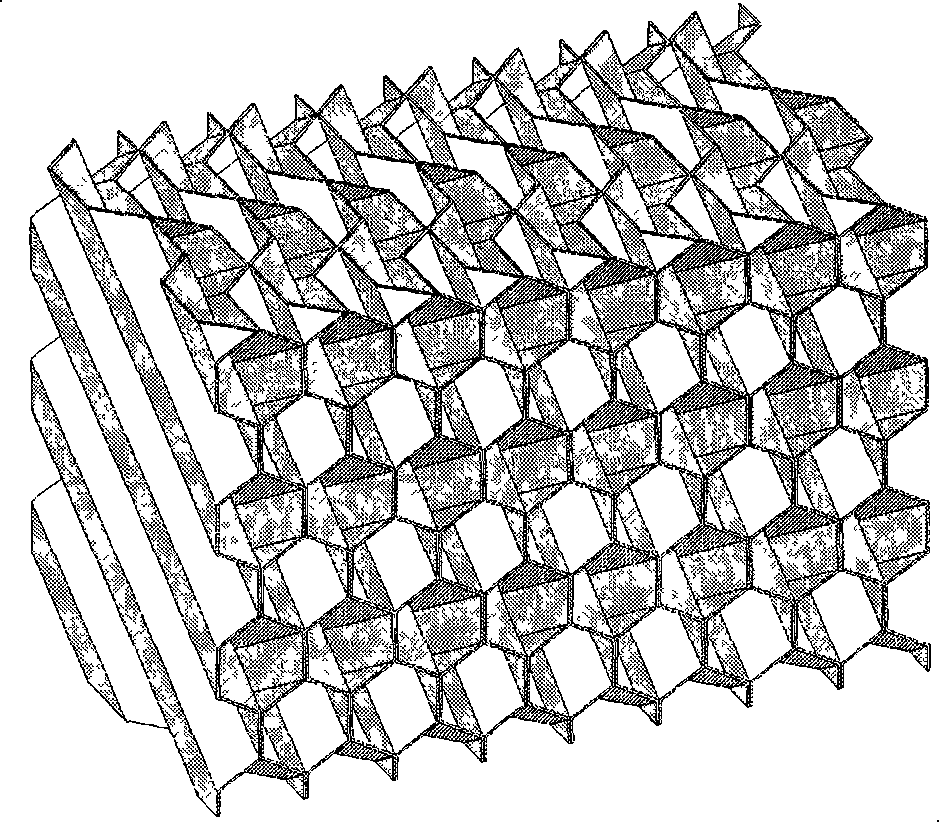

[0030] Referring to accompanying drawing 1, the present invention is made of crude oil emulsion inlet (1), tubular electrode assembly (2), emulsion uniform distributor (3), spoiler (4), interlaced corrugated coalescing plate (5), water Outlet (6), crude oil outlet (7), vent (8), electrostatic dehydrator housing (9), high-voltage transformer (10), electrostatic dehydrator housing (11), high-voltage insulated cable (12) and other components. The invention is divided into a vertically installed coalescing part (11) and a horizontally arranged settling separation part (9), which are welded to each other to form an integral body. The coalescing part (11) is located in the upper part of the dehydrator and is a vertical cylindrical structure with a small volume, and a cylindrical electrode assembly (2) is installed inside; the sedimentation separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com