Spina gleditsiae-based bacteriostatic and antiallergic shampoo and preparation method thereof

A saponin thorn and anti-allergic technology, applied in the field of daily chemical cleaning products, can solve problems such as difficult separation and identification, and achieve the effect of complete utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

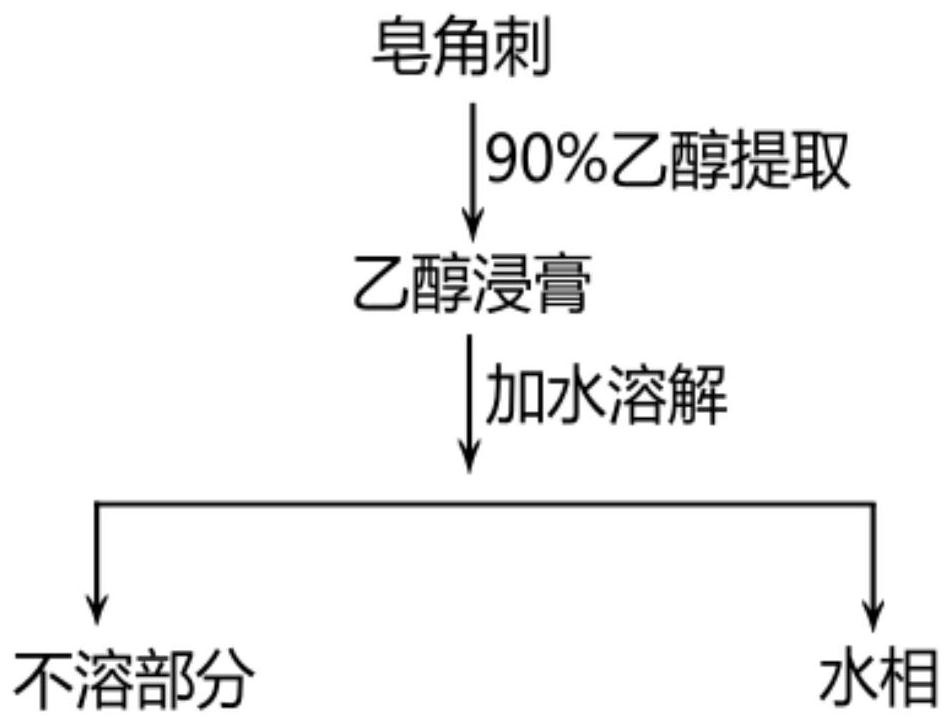

[0033] Such as figure 1 As shown, saponins were heated in a 40°C oven, dried for 10 hours, dried, and used; under the conditions of ultrasonic power of 100W and ultrasonic time of 40min, they were pulverized into smaller particles (with a particle size of less than 1mm) by a pulverizer. ), stand-by; put 1 kg of saponin root powder after crushing into 90% ethanol with 3L volume in a plastic bucket, soak for 24h, and the temperature of soaking is 50°C; Extraction: put the extract in a hot water pot at 90°C, fully dissolve; filter the insoluble matter, and the obtained saponin liquid is the saponin root water extract, which is counted as 40 parts; Add 1 part of ammonium lauryl ether sulfate (70%) to the extract, and stir evenly; add 10 parts of saponin rice water extract, and stir evenly; add 4 parts of glycerin and 10 parts of honey, and stir evenly; add the remaining amount of water, and stir Evenly, you get a shampoo.

Embodiment 2

[0035] The saponins are heated in an oven at 60°C, dried for 5 hours, dried, and used; under the conditions of ultrasonic power of 50W and ultrasonic time of 55min, they are pulverized into smaller particles (within 1mm in particle size) with a pulverizer, and wait for use. Use; put 1 kg of crushed saponin thorn powder into a plastic bucket filled with 3L of 90% ethanol, soak for 38 hours, and the soaking temperature is 60°C; after the ethanol is heated and volatilized or dried naturally, the extract is obtained; Put the extract in a hot water pot at 80°C, fully dissolve; filter the insoluble matter, and the obtained saponin liquid is the saponin thorn water extract, which is counted as 40 parts; Add 2 parts of ammonium lauryl ether sulfate (70%), stir well; add 5 parts of saponin rice water extract, stir well; add 2 parts of glycerin and 5 parts of honey, stir well; add water to the remaining amount, stir well, that is Gotta shampoo.

Embodiment 3

[0037] The saponins are heated in a 40°C oven, dried for 10 hours, dried, and used; under the condition of ultrasonic power of 500W and ultrasonic time of 10min, use a pulverizer to pulverize into smaller particles (within a particle size of 1mm), and wait for use. Use; put 1 kg of crushed saponin thorn powder into a plastic bucket filled with 3L of 90% ethanol, soak for 72 hours, and the soaking temperature is 50°C; after the ethanol is heated and volatilized or dried naturally, the extract is obtained; Put the extract in a hot water pot at 100°C and dissolve it fully; filter the insoluble matter, and the obtained saponin liquid is the saponin root water extract, which is counted as 40 parts; add it to the saponin root water extract successively Add 2 parts of ammonium lauryl ether sulfate (70%), stir well; add 5 parts of saponin rice water extract, stir well; add 2 parts of glycerin and 5 parts of honey, stir well; add water to the remaining amount, stir well, that is Gotta ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com