Method for synthesizing degradable polyurethane by using corncob and industrial capsicum waste residue

A technology of corn cob and polyurethane, which is applied in the field of degradable polyurethane preparation, can solve the problems of large cells, dark color, and high density, and achieve the effect of fine cells, light color, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

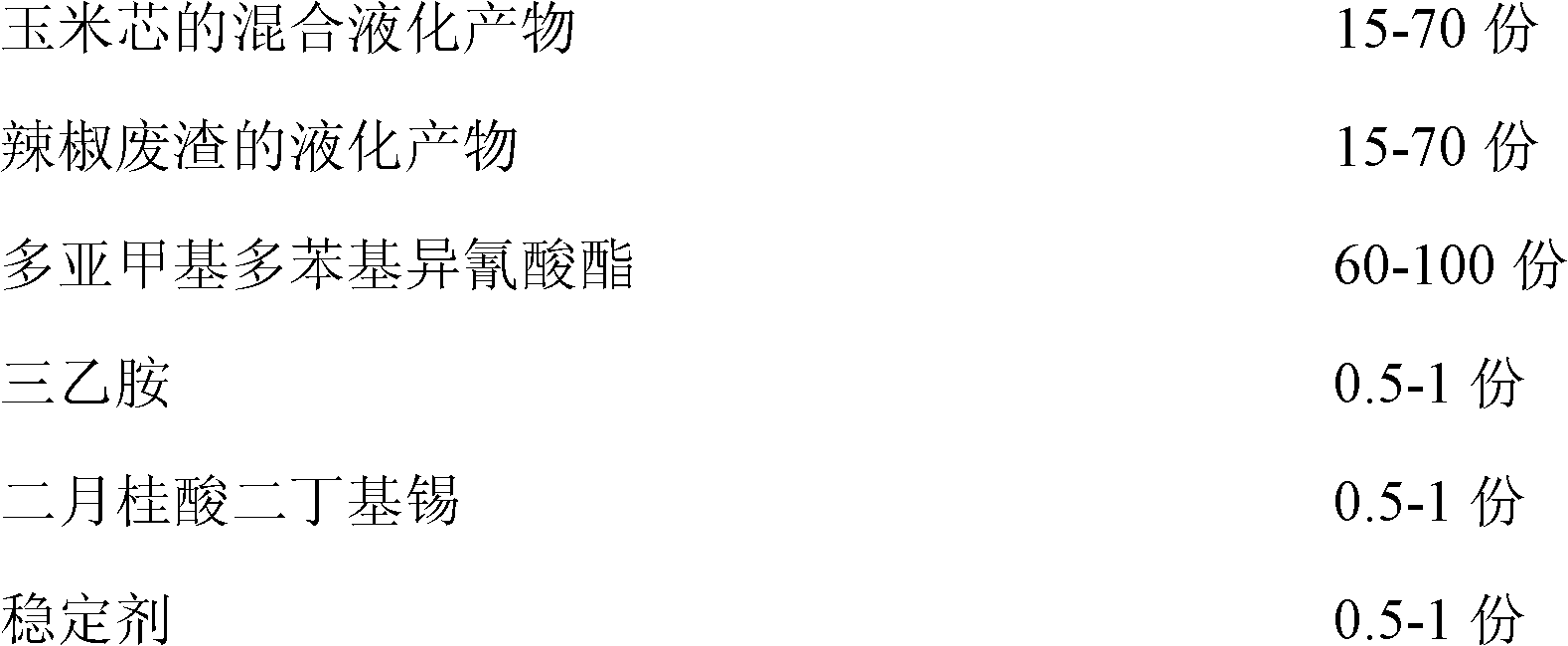

Image

Examples

Embodiment 1

[0036] A method for synthesizing degradable polyurethane by using corn cobs and industrial pepper waste residues, according to the following steps:

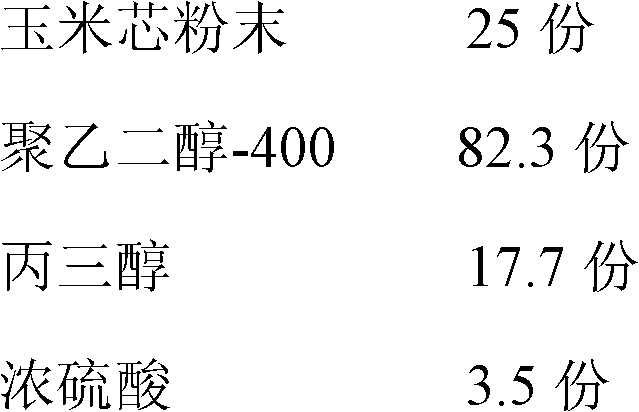

[0037] (1), preparation of corn cob liquefaction product

[0038] Take the corn cob, crush it, sieve it, and take the 20-80 mesh part, dry it at 90-120 degrees Celsius to the balance weight, and make the corn cob powder;

[0039] (2) get the raw material of following parts by weight:

[0040]

[0041] Mix polyethylene glycol-400, glycerin and concentrated sulfuric acid evenly in a three-necked flask, heat to 160 degrees Celsius in an oil bath, stir at 100r / min, then add corncob powder to react for 60min, and quickly cool to room temperature to obtain corncob liquefaction products.

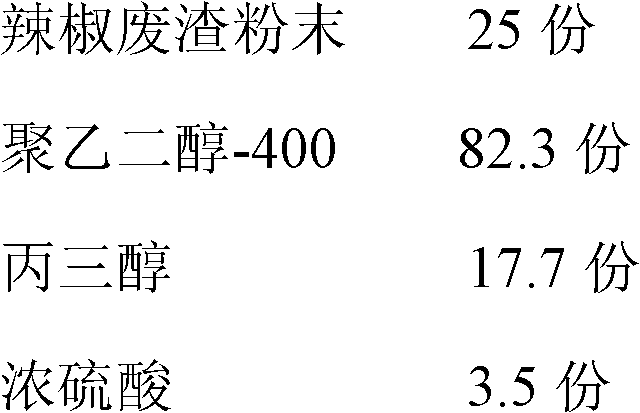

[0042] (2) Preparation of liquefied product of industrial chili waste residue

[0043] Take the industrial chili waste residue, crush and sieve the 20-80 mesh part, dry it at 90-120 degrees Celsius to the balance weight, and make the chili waste...

Embodiment 2

[0053] A method for synthesizing degradable polyurethane by using corn cobs and industrial pepper waste residues, according to the following steps:

[0054] (1), preparation of corn cob liquefaction product

[0055] The corncobs are crushed and sieved to take the 20-80 mesh part, and dried at 90-120 degrees Celsius to a constant weight to obtain the corncob powder.

[0056] Get the raw material of following parts by weight:

[0057]

[0058] Mix polyethylene glycol-400, glycerin and concentrated sulfuric acid evenly in a three-necked flask, heat to 160 degrees Celsius in an oil bath, stir at 100r / min, then add corncob powder to react for 60min, and quickly cool to room temperature to obtain corncob liquefaction products.

[0059] (2) Preparation of liquefied product of industrial chili waste residue

[0060] Take the industrial chili waste residue, crush and sieve the 20-80 mesh part, dry it at 90-120 degrees Celsius to the balance weight, and make the chili waste residu...

Embodiment 3

[0070] A method for synthesizing degradable polyurethane by using corn cobs and industrial pepper waste residues, according to the following steps:

[0071] (1), preparation of corn cob liquefaction product

[0072] Take corn cobs, grind them, sieve them, and take 20-80 mesh parts, dry them at 90-120 degrees Celsius to the constant weight, and make corn cob powder;

[0073] Get the raw material of following parts by weight:

[0074]

[0075] Mix polyethylene glycol-400, glycerin, and concentrated sulfuric acid evenly in a three-necked flask, heat to 145 degrees Celsius in an oil bath, stir at 100r / min, then add corncob powder to react for 60min, and quickly cool to room temperature to obtain corncob liquefaction products.

[0076] (2) Preparation of liquefied product of industrial chili waste residue

[0077] Take the industrial chili waste residue, pulverize and sieve the 20-80 mesh part, dry it at 90-120 degrees Celsius to the balance weight, and obtain the chili waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com