Phosphogypsum granular soil and preparation method thereof

A technology of phosphogypsum and granules, which is applied in the field of phosphogypsum granular soil and its preparation, can solve the problems of multi-yard construction and maintenance costs, reduce crop yield and quality, occupy land and farmland, etc., and achieve good water and fertilizer conservation functions, The effect of meeting the needs of plant growth and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

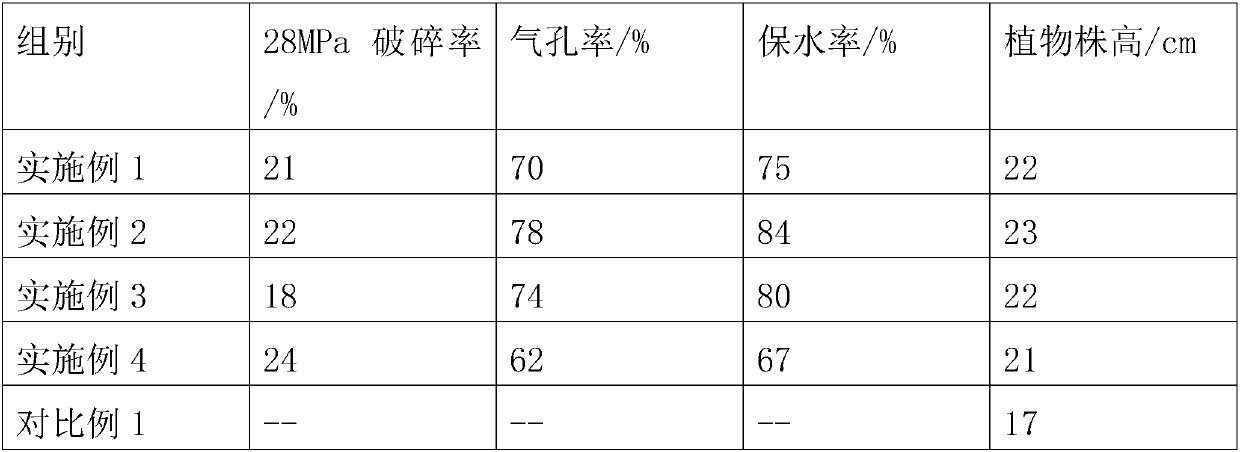

Examples

Embodiment 1

[0042] A phosphogypsum granular soil, comprising the following components by weight:

[0043] 100 parts of phosphogypsum;

[0044] 5 parts of bentonite;

[0045] 10 parts of expanded perlite;

[0046] 1 part of polycarboxylate superplasticizer;

[0047] 20 parts of neutral silica sol solution (20% solid content).

[0048] The preparation method of phosphogypsum granular soil in the present embodiment comprises the following steps:

[0049] (1) Weigh each raw material component according to the formula requirements, put phosphogypsum, bentonite, expanded perlite, polycarboxylate superplasticizer in a mixer and mix evenly to obtain a mixture;

[0050] (2) Pour the mixture obtained in step (1) into a high-speed granulator, and spray neutral silica sol solution while granulating at a rotating speed of 20m / s;

[0051] (3) Put the prepared granules into a drying oven at 100°C for drying;

[0052] (4) After the dried granules are screened, the granular soil is obtained after si...

Embodiment 2

[0055] A phosphogypsum granular soil, comprising the following components by weight:

[0056] 100 parts of phosphogypsum;

[0057] 8 parts of calcined kaolin;

[0058] 20 parts of expanded perlite;

[0059] Naphthalene-based superplasticizer 1.5 parts;

[0060] 15 parts of neutral silica sol solution (20% solid content).

[0061] The preparation method of phosphogypsum granular soil in the present embodiment comprises the following steps:

[0062] (1) Weigh each raw material component according to the formula requirements, put phosphogypsum, calcined kaolin, expanded perlite, and naphthalene-based high-efficiency water reducer in a mixer and mix evenly to obtain a mixture;

[0063] (2) Pour the mixture obtained in step (1) into a high-speed granulator, and spray neutral silica sol solution while granulating at a rotating speed of 40m / s;

[0064] (3) Put the prepared granules into an oven at 80°C for drying;

[0065] (4) The dried granules are sieved and sintered to obtain ...

Embodiment 3

[0068] A phosphogypsum granular soil, comprising the following components by weight:

[0069] 100 parts of phosphogypsum;

[0070] 10 parts white clay;

[0071] 15 parts of expanded perlite;

[0072] 1.2 parts of fatty acid superplasticizer;

[0073] 25 parts of neutral silica sol solution (30% solid content).

[0074] The preparation method of phosphogypsum granular soil in the present embodiment comprises the following steps:

[0075] (1) Weigh each raw material component according to the formula requirements, put phosphogypsum, white mud, expanded perlite, and fatty acid-based high-efficiency water reducer in a mixer and mix evenly to obtain a mixture;

[0076] (2) Pour the mixture obtained in step (1) into a high-speed granulator, and spray neutral silica sol solution while granulating at a rotating speed of 50m / s;

[0077] (3) Put the prepared granules into a drying oven at 70°C for drying;

[0078] (4) After the dried granules are screened, the granular soil is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com