Construction waste artificial soil

A technology for artificial soil and construction waste, applied in planting substrates, horticulture, botanical equipment and methods, etc., to achieve the effects of reducing raw material costs, reducing pollution, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

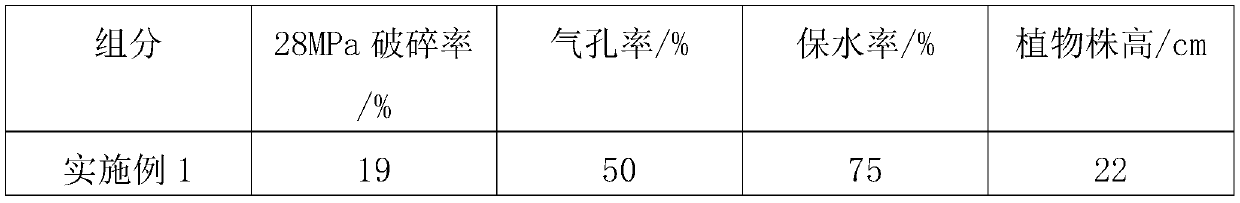

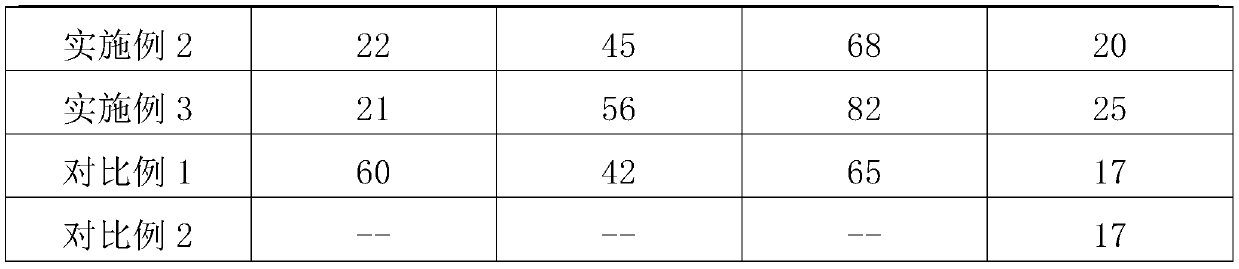

Examples

Embodiment 1

[0034] A construction waste artificial soil is prepared by the following method:

[0035] (1) Take 100 parts of construction waste powder, 10 parts of calcined kaolin, 15 parts of slag, 40 parts of phosphogypsum, and 10 parts of steel slag and mix them uniformly in a mixer to obtain a mixture for use;

[0036] (2) Pour the mixture into the ceramic sand high-speed granulator, and spray 30 parts of water while granulating at a speed of 20m / s;

[0037] (3) Put the prepared grains into a curing box with a temperature of 40° C. and a humidity of 90% for curing for one day; after the cured grains are sieved, artificial soil meeting the particle size requirement is obtained.

[0038] The chemical composition of construction waste powder in the present embodiment is: SiO 2 52wt%, Al 2 o 3 12wt%, CaO15wt%, MgO 2wt%, Fe 2 o 3 5wt%, K 2 O 1wt%, loss on ignition 13wt%.

[0039] Take 400mL of the artificial soil prepared above and spread it in a 500mL flowerpot, insert the garlic...

Embodiment 2

[0041] A construction waste artificial soil is prepared by the following method:

[0042] (1) Take by weighing 100 parts of construction waste powder, 5 parts of bentonite, 10 parts of slag, 20 parts of phosphogypsum, and 10 parts of steel slag and mix them uniformly in a mixer to obtain a mixture for use;

[0043] (2) Pour the mixture into the ceramic sand high-speed granulator, and spray 25 parts of water while granulating at a rotating speed of 50m / s;

[0044](3) Put the prepared grains into a curing box with a temperature of 25° C. and a humidity of 80% for curing for 3 days; after the cured grains are sieved, artificial soil meeting the particle size requirement is obtained.

[0045] The chemical composition of construction waste powder in the present embodiment is: SiO 2 50wt%, Al 2 o 3 12wt%, CaO18wt%, MgO 2wt%, Fe 2 o 3 4wt%, K 2 O 3wt%, loss on ignition 11wt%.

[0046] Take 400mL of the artificial soil prepared above and spread it in a 500mL flowerpot, inser...

Embodiment 3

[0048] A construction waste artificial soil is prepared by the following method:

[0049] (1) Take by weighing 100 parts of construction waste powder, 20 parts of slag, 30 parts of phosphogypsum, and 5 parts of steel slag and mix them uniformly in a mixer to obtain a mixture for use;

[0050] (2) Pour the mixture into the ceramic sand high-speed granulator, and spray 20 parts of water while granulating at a speed of 20m / s;

[0051] (3) Put the prepared grains into a curing box with a temperature of 40° C. and a humidity of 90% for curing for one day; after the cured grains are sieved, artificial soil meeting the particle size requirement is obtained.

[0052] The chemical composition of construction waste powder in the present embodiment is: SiO 2 55wt%, Al 2 o 3 10wt%, CaO12wt%, MgO 5wt%, Fe 2 o 3 3wt%, K 2 O 2wt%, loss on ignition 13wt%.

[0053] Take 400mL of the artificial soil prepared above and spread it in a 500mL flowerpot, insert the garlic in the artificial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com