Planting sand and its preparation method

A solid waste and component technology, applied in the field of sand planting, can solve the problems of poor water and fertilizer retention of sand, single fixed element components, etc., and achieve the effect of meeting the needs of plant growth, uniform distribution, and conducive to plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

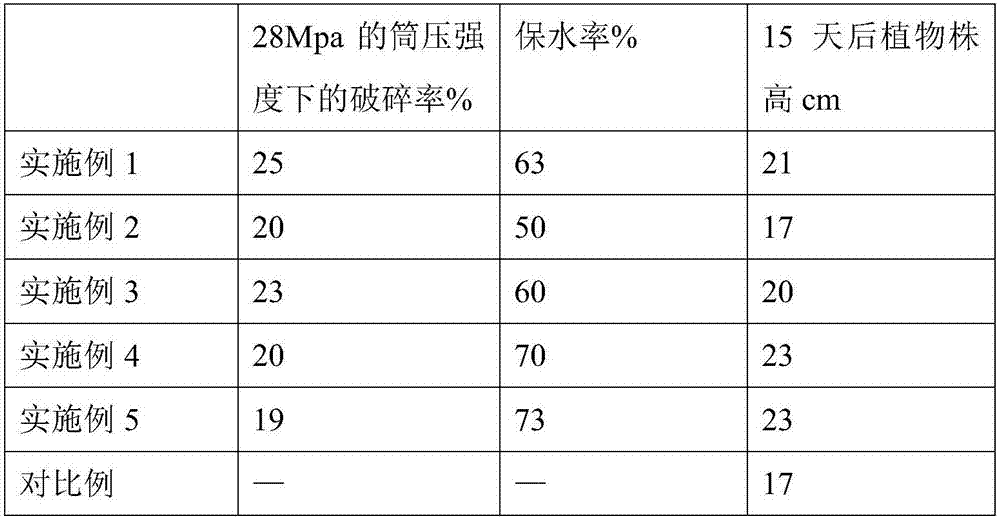

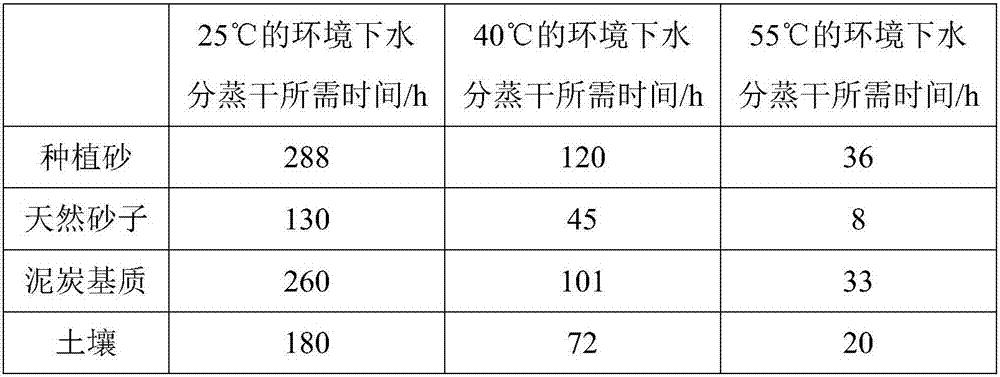

Examples

Embodiment 1

[0032] (1) Weigh 100 parts of fly ash, 10 parts of bentonite, 10 parts of expanded perlite and 1 part of sodium lignosulfonate, and mix them uniformly in a blender for later use;

[0033] (2) Pour the mixture obtained in step (1) into a pottery sand granulator, and take 25 parts of water and pour it into the granulator, and granulate at a rotating speed of 2000r / min;

[0034] (3) Put the prepared granules into a drying oven at 70°C for drying;

[0035] (4) The dried grains are heated at 30°C / min to 600°C, then at 3°C / min to 700°C, and finally at 20°C / min to 1000°C for 20 minutes to obtain planting sand. ;

[0036] (5) Take 400mL of the planting sand prepared above and spread it in a 500mL flower pot, insert garlic into the planting sand, add 150mL of the prepared nutrient solution (1wt%), observe and record the growth of the garlic seedlings.

Embodiment 2

[0038] (1) Weigh 100 parts of fly ash, 10 parts of bentonite and 1 part of sodium lignin sulfur, and mix them uniformly in a blender for later use;

[0039] (2) Pour the mixture obtained in step (1) into a pottery sand granulator, and take 20 parts of water and pour it into the granulator, and granulate at a rotating speed of 2500r / min;

[0040] (3) Put the prepared granules into a drying oven at 100°C for drying;

[0041] (4) The dried grains are heated to 600°C at 25°C / min, then to 700°C at 4°C / min, and finally to 950°C at 15°C / min for 30 minutes to obtain planting sand;

[0042] (5) Take 400mL of the planting sand prepared above and spread it in a 500mL flower pot, insert garlic into the planting sand, add 150mL of the prepared nutrient solution (1wt%), observe and record the growth of the garlic seedlings.

Embodiment 3

[0044] (1) Weigh 100 parts of coal gangue fine powder, 5 parts of kaolin, 10 parts of vermiculite and 1.5 parts of polycarboxylate superplasticizer, and mix them uniformly in a mixer for use;

[0045] (2) Pour the mixture obtained in step (1) into the pottery sand granulator, and take 30 parts of water and pour it into the granulator, and granulate at a rotating speed of 3000r / min;

[0046] (3) Put the prepared granules into a drying oven at 120°C for drying;

[0047] (4) The dried grains are heated to 600°C at 35°C / min, then to 700°C at 3°C / min, and finally to 1000°C at 15°C / min for 30 minutes to obtain planting sand;

[0048] (5) Take 400mL of the planting sand prepared above and spread it in a 500mL flower pot, insert garlic into the planting sand, add 150mL of the prepared nutrient solution (1wt%), observe and record the growth of the garlic seedlings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com