Water-retaining thickening and strengthening additive for cement mortar and cement mortar containing additive

A technology for water retention and thickening, cement mortar, applied in the field of building materials, can solve the problems of high water demand, easy cracking cost of mortar, high cement consumption, and achieve the effect of reducing cement consumption, improving work performance, and increasing mortar strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention provides a water-retaining thickening additive for cement mortar that is corn stalk modified cellulose; wherein, the corn stalk modified cellulose is a by-product cellulose produced by refining hemicellulose from corn stalks as a raw material. The sodium hydroxide solution adjusts its pH value to 7.6, puts it into a dryer for drying, and grinds it into solid powder to ensure that the passing rate of the powder through a 60-mesh sieve is greater than 95%, so as to obtain the corn stalk modified cellulose.

[0040] The preparation method of the cement mortar containing the above-mentioned water-retaining thickening reinforcing material is as follows: weigh each component according to the weight ratios described in Table 1, and mix them uniformly by physical machinery to obtain the mortar of the present invention.

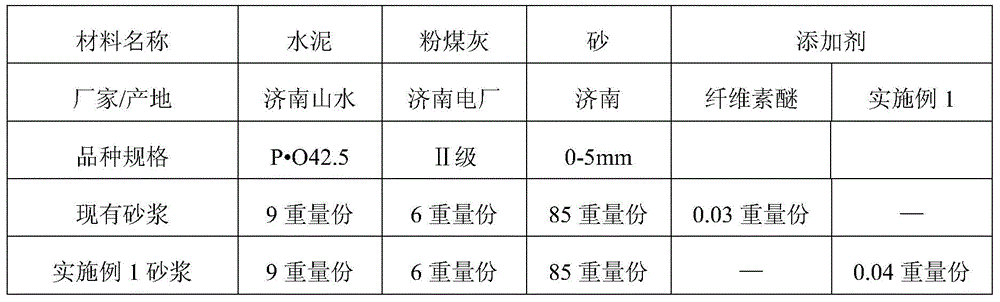

[0041] Table 1: Contrast Table of the Mixing Ratio of Existing Cement Mortar and Embodiment 1

[0042]

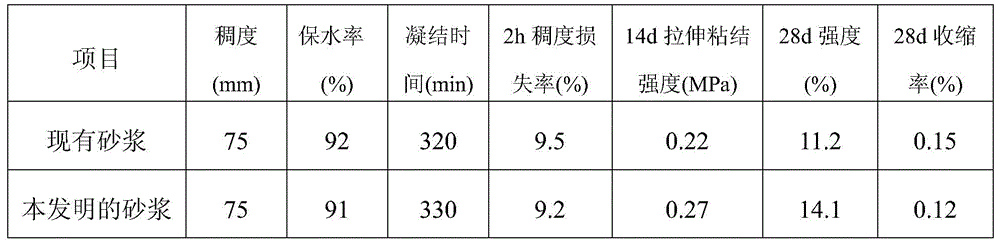

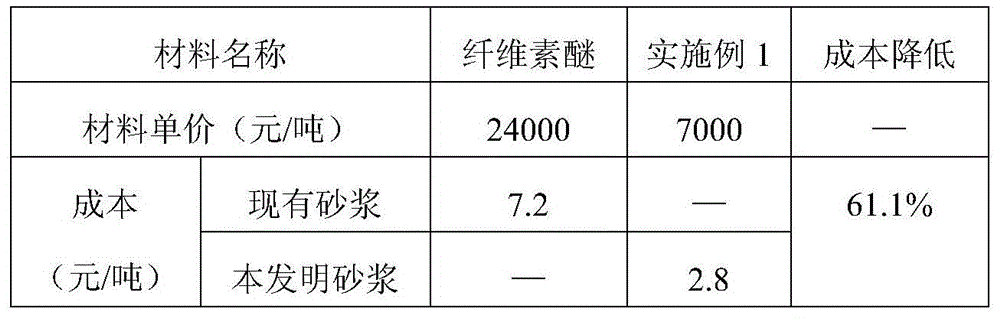

[0043] Table ...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a cement mortar water-retention thickening and strengthening additive, wherein the parts by weight of the components in the additive are: 95 parts by weight of corn straw modified cellulose, 25 parts by weight of cellulose ether and 30 parts by weight of sodium gluconate parts by weight; wherein, the corn stalk modified cellulose is made of the by-product cellulose produced by refining hemicellulose from corn stalks as a raw material, its pH value is adjusted to 7.5 with sodium hydroxide solution, and then it is put into a dryer for drying and then ground into The powder is solid, and the passing rate of the 60-mesh sieve of the powder is guaranteed to be greater than 95%, so as to obtain the corn stalk modified cellulose.

[0050] Table 4: Comparison Table of the Mixing Ratio of Existing Cement Mortar and the Cement Mortar of Example 2

[0051]

[0052] Table 5: Comparison table of performance testing results of existin...

Embodiment 3

[0058] Embodiment 3 of the present invention provides a water-retaining thickening and enhancing additive for cement mortar, wherein the parts by weight of the components in the additive are: 74 parts by weight of corn straw modified cellulose, 14 parts by weight of cellulose ether, 15 parts by weight of sodium gluconate Parts by weight, 36 parts by weight of high-efficiency water reducer; Among them, corn stalk modified cellulose is the by-product cellulose produced by refining hemicellulose from corn stalks as raw material, and its pH value is adjusted to 7.5 with sodium hydroxide solution, and then put into drying After drying in a dryer, it is ground into a solid powder to ensure that the passing rate of the 60-mesh sieve of the powder is greater than 95%, and the corn straw modified cellulose is obtained; the high-efficiency water reducer is a naphthalene-based water reducer and a sulfamate water reducer.

[0059] Table 7: Contrast Table of the Mixing Ratio of the Existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com