Method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking

A technology for coking gasoline and aromatics, applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, purification/separation of hydrocarbons, etc., can solve the problems of high energy consumption, extend the coke cleaning cycle, reduce the coking rate and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

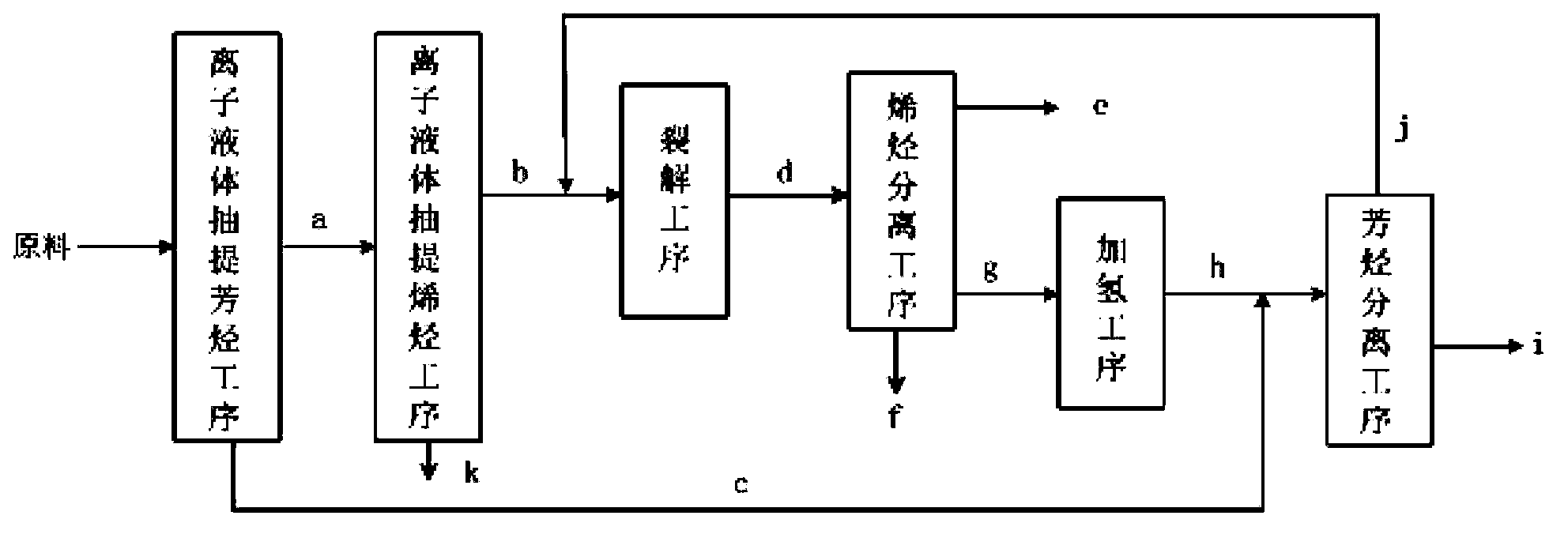

Method used

Image

Examples

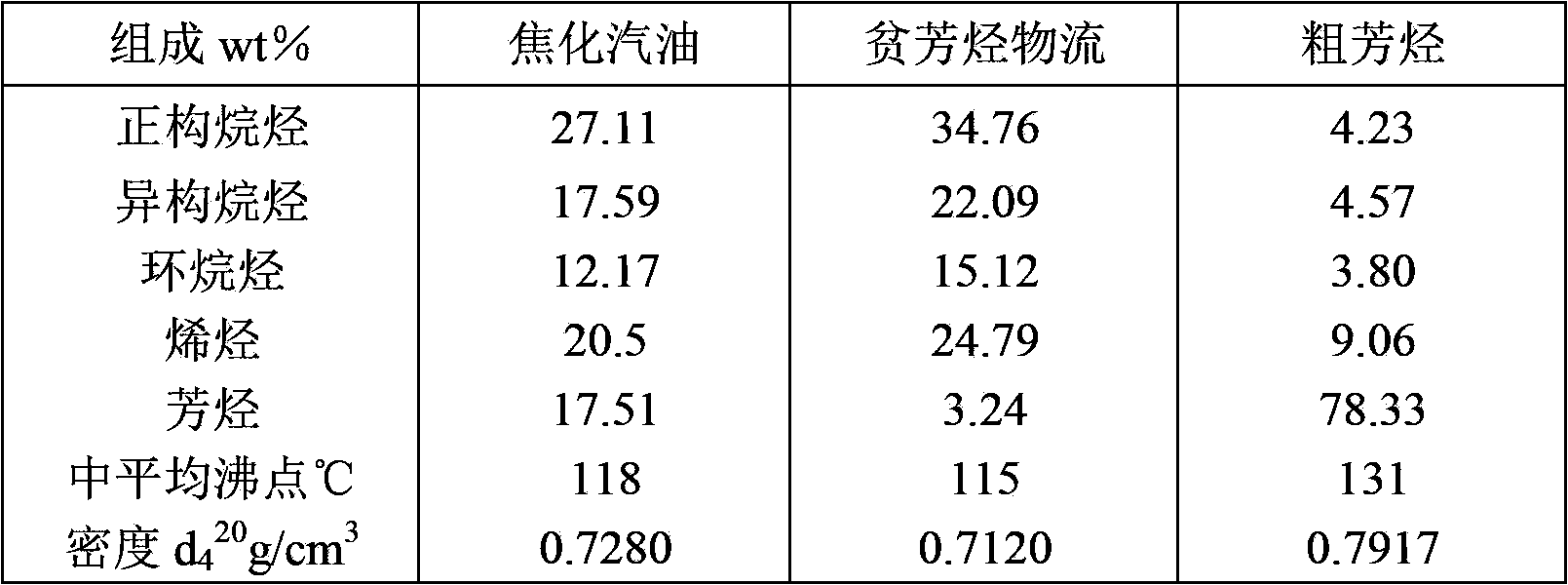

Embodiment 1

[0034] A kind of coker gasoline is used as raw material, and its raw material properties are shown in Table 1. Send it to the experimental device for extracting aromatics with ionic liquid solvent. The extraction device is a rotating disk extraction tower with 50 actual trays and countercurrent operation. The ionic liquid solvent is methylbutylpyridine tetrafluoroborate [mebupy] [BF 4 ], the mol ratio of solvent to raw oil is 2.5, the extraction tower operates under normal pressure, and the extraction temperature is 55°C; the rich solvent flowing out from the bottom of the extraction tower is stripped by nitrogen to recover the solvent. The raffinate at the top of the tower is passed through activated carbon to absorb the solvent to obtain an aromatics-poor stream. The aromatics content of the aromatic-lean stream was 3.24w%, the sulfur content dropped to 1056 μg / g, and the nitrogen content dropped to 10.30 μg / g; the aromatics content of the crude aromatics stream was 78.33w...

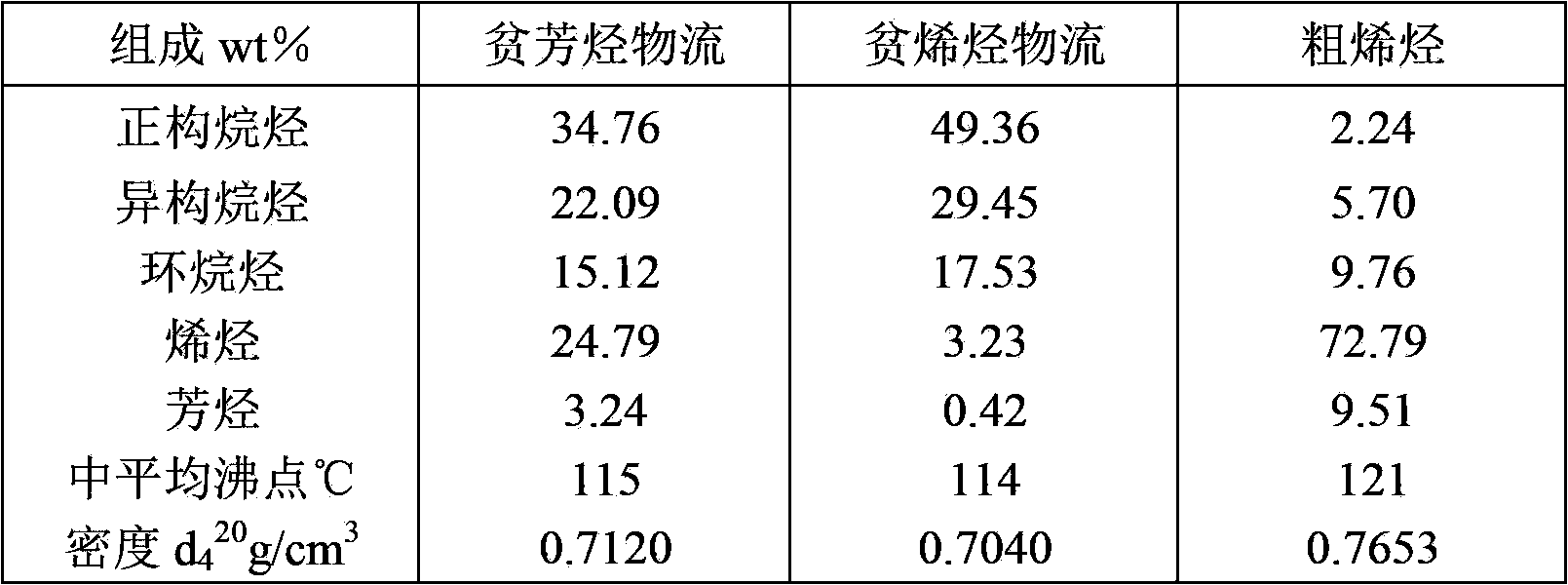

Embodiment 2

[0041] The aromatic-poor stream obtained in Example 1 was sent to an experimental device for extracting olefins with an ionic liquid solvent. The extraction device is a rotating disk extraction tower with 50 actual trays and countercurrent operation. The ionic liquid solvent is 1-butyl-3-methylimidazolium tetrafluoroborate [BMIM][BF 4 ], and added 19mol% of AgBF 4 , the molar ratio of solvent to raw oil is 3, the extraction tower operates under normal pressure, and the extraction temperature is 45°C; the rich solvent flowing out from the bottom of the extraction tower is stripped by nitrogen to recover the solvent. The raffinate at the top of the tower is passed through the activated carbon to absorb the solvent to obtain an olefin-depleted stream. The olefin content of the olefin-lean stream is 3.23wt%, the aromatics content is 0.42wt%, the sulfur content is reduced to 381μg / g, and the nitrogen content is reduced to 2.01μg / g; the olefin content of the crude olefin stream is...

Embodiment 3

[0046] The olefin-lean stream obtained in Example 2 is heated to 60°C and mixed with water vapor heated to 180°C at a dilution ratio of 0.5, and then introduced into the tube furnace hydrocarbon thermal cracking reactor, and the operating temperature is 835°C. The cleavage reaction was carried out under the condition of 0.247s, and the C-rich 2 Alkenes, C 3 Alkenes and C 4 Products of olefins, cracked fuel oils and C 6 ~C 9 The hydrocarbon mixture of aromatics, the yield of the main product of cracking is shown in Table 4; 6 ~C 9 After hydrogenation, the hydrocarbon mixture of aromatics is mixed with the crude aromatics stream to enter the aromatics separation process to obtain aromatics products such as benzene, toluene, and xylene. The total yield of aromatics is shown in Table 5.

[0047] Table 4: Cleavage yields of major cleavage products

[0048]

[0049] Table 5: Total Aromatics Yield

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com