Preparation method of base oil of transformer oil

A technology for transformer oil and transformers, which is applied in the field of preparing transformer oil base oil by utilizing a heavy hydrocarbon oil thermal cracking process, can solve the problems of poor oxidation stability of polycyclic aromatic hydrocarbons, easy oxidative discoloration, and formation of precipitation, and achieves widening the source of raw materials. , good viscosity-temperature performance, solve the effect of a single source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

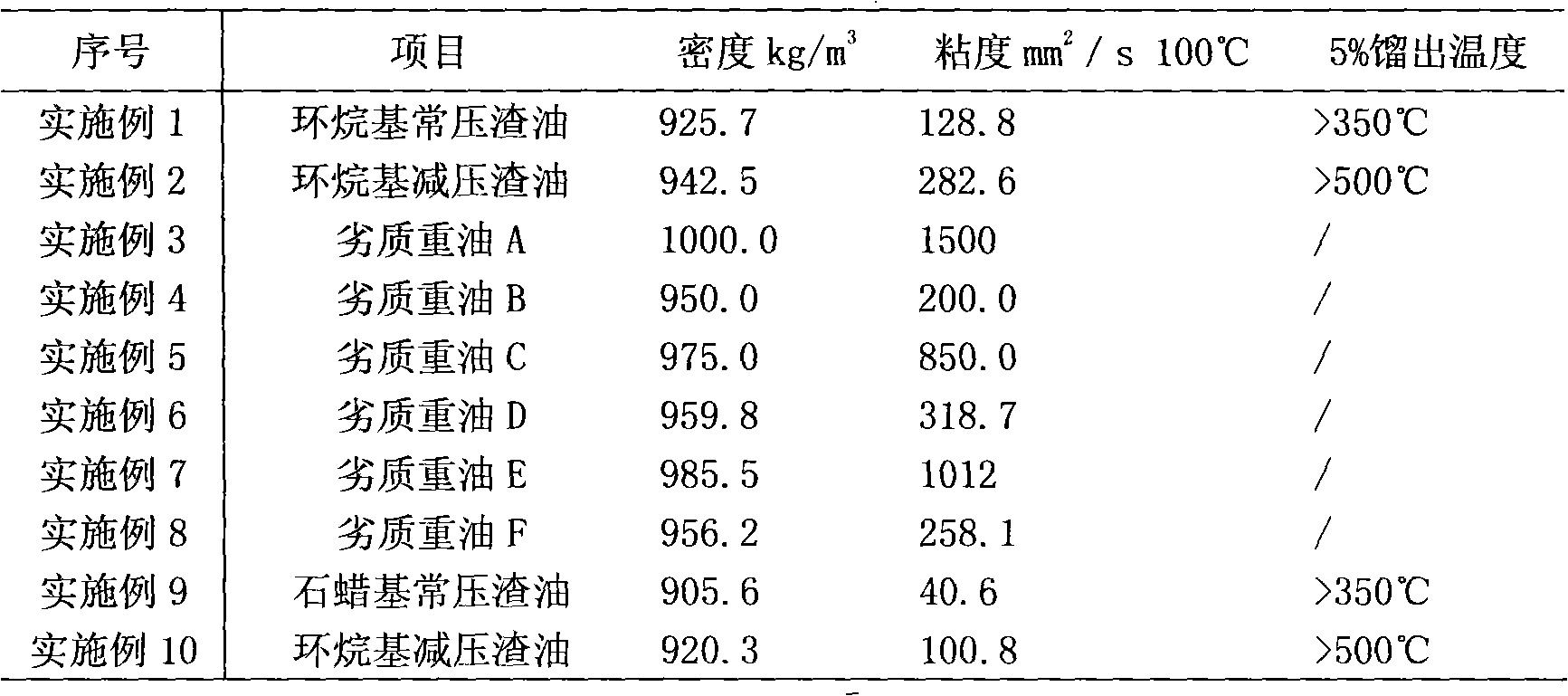

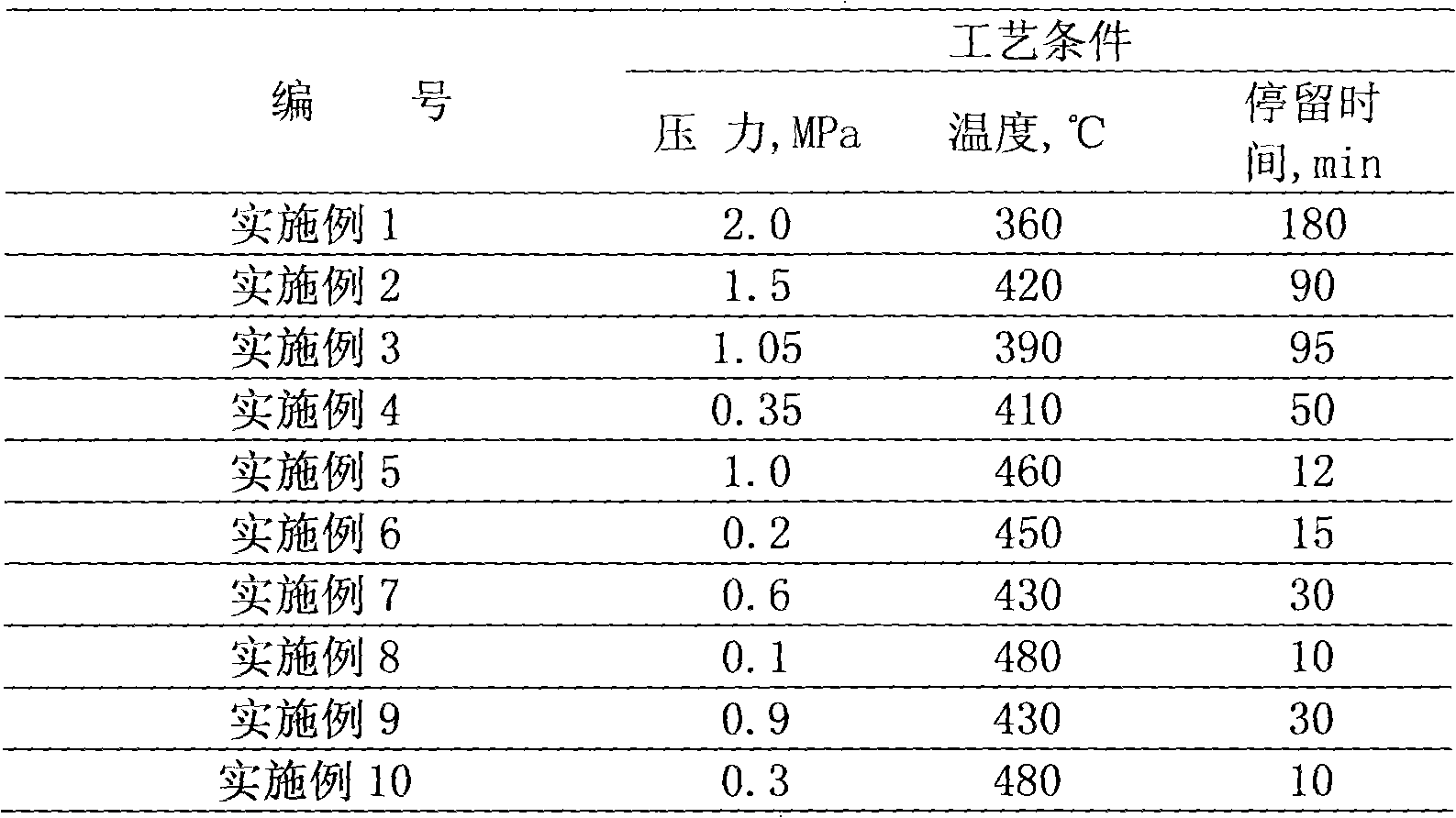

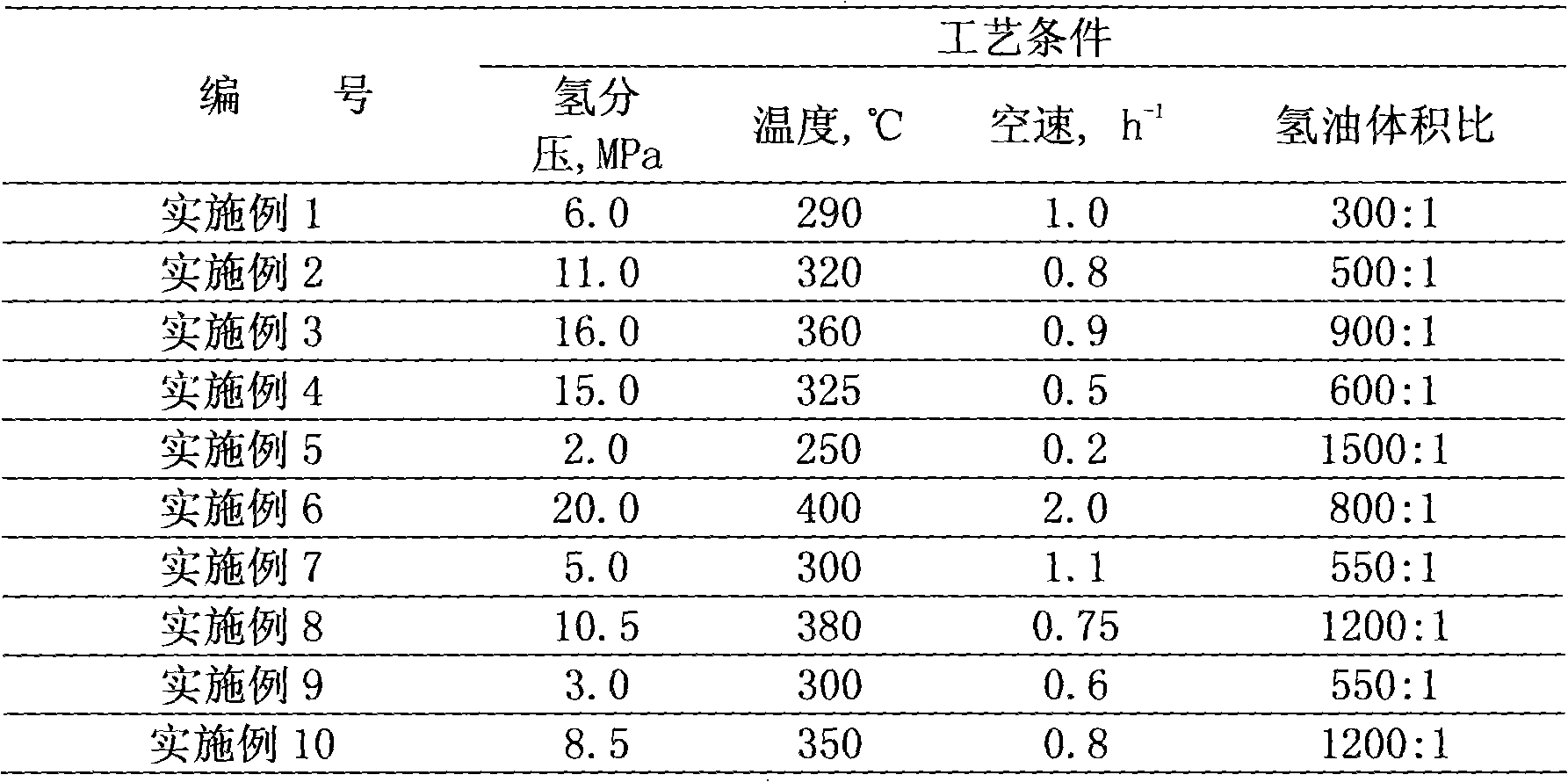

Embodiment 1

[0019] The naphthenic residual oil is used as the raw material, and the properties of the raw material are shown in Table 1. The thermal cracking process is carried out, and the operating conditions of the thermal cracking process are shown in Table 2. The raw material of transformer oil base oil is obtained by fractional cutting, and the raw material is processed by hydrogenation, furfural, decondensation and clay production process to obtain transformer base oil. The operating parameters of each production process are shown in Table 3, Table 4, Table 5, and Table 6. The viscosity-temperature performance of the base oil is shown in Table 6, and the properties of the hydrogenation catalyst are shown in Table 7. The base oil complies with IEC60296(2003), ASTM D3487, GB 2536-90 and SH0040-91 standards.

Embodiment 2

[0021]Using naphthenic-based reduced residual oil as raw material, the properties of the raw material are shown in Table 1, and the thermal cracking process is carried out, and the operating conditions of the thermal cracking process are shown in Table 2. The raw material of transformer oil base oil is obtained by fractional cutting, and the raw material is processed by hydrogenation, furfural, decondensation and clay production process to obtain transformer base oil. The operating parameters of each production process are shown in Table 3, Table 4, Table 5, and Table 6. The viscosity-temperature properties of the base oil are shown in Table 6, and the property analysis of the hydrogenation catalyst is shown in Table 7. The base oil complies with IEC60296(2003), ASTM D3487, GB 2536-90 and SH0040-91 standards.

Embodiment 3

[0023] Inferior heavy oil A is used as raw material, and the properties of the raw material are shown in Table 1, and a thermal cracking process is carried out, and the operating conditions of the thermal cracking process are shown in Table 2. The raw material of transformer oil base oil is obtained by fractional cutting, and the raw material is processed by hydrogenation, furfural, decondensation and clay production process to obtain transformer base oil. The operating parameters of each production process are shown in Table 3, Table 4, Table 5, and Table 6. The viscosity-temperature properties of the base oil are shown in Table 6, and the property analysis of the hydrogenation catalyst is shown in Table 7. The base oil complies with IEC60296(2003), ASTM D3487, GB 2536-90 and SH0040-91 standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com