Method for extracting and separating chlorogenic acid from chrysanthemum

A technology of chlorogenic acid and goldenrod, which is applied to chemical instruments and methods, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve the problems of inability to extract a single component and low extraction rate, and achieve good economic benefits and improve The effect of extraction efficiency and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: extraction treatment and analysis (flower or leaf)

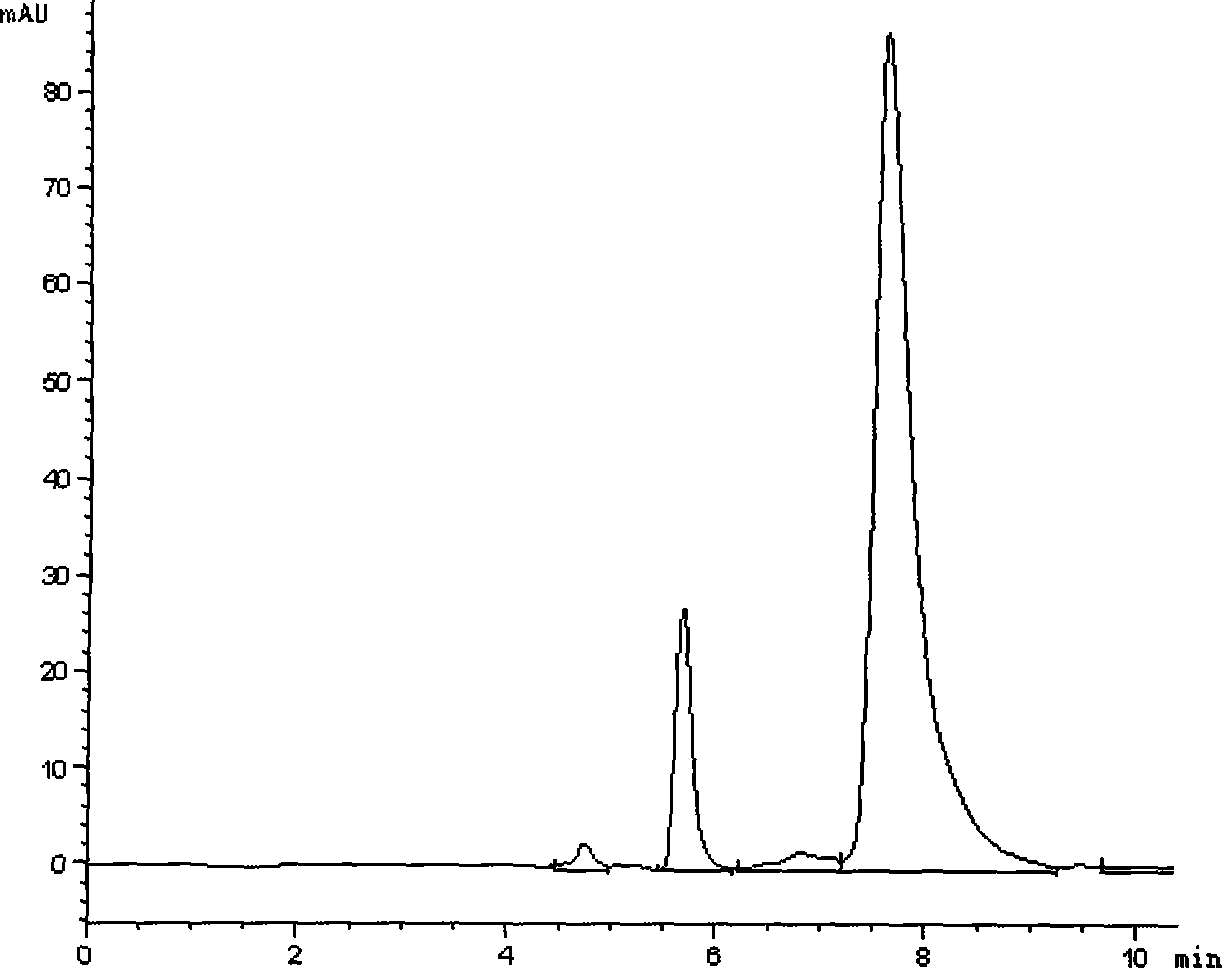

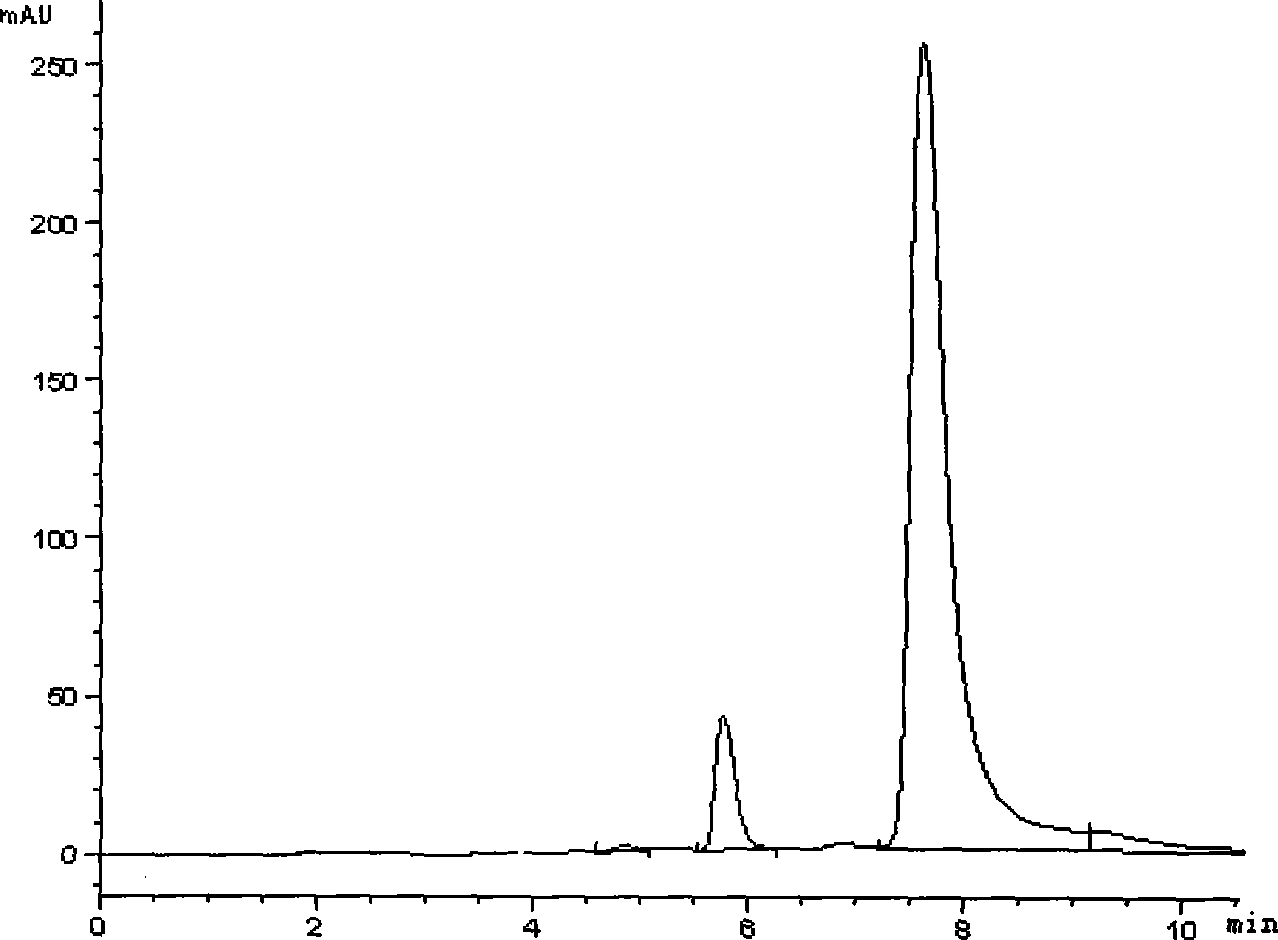

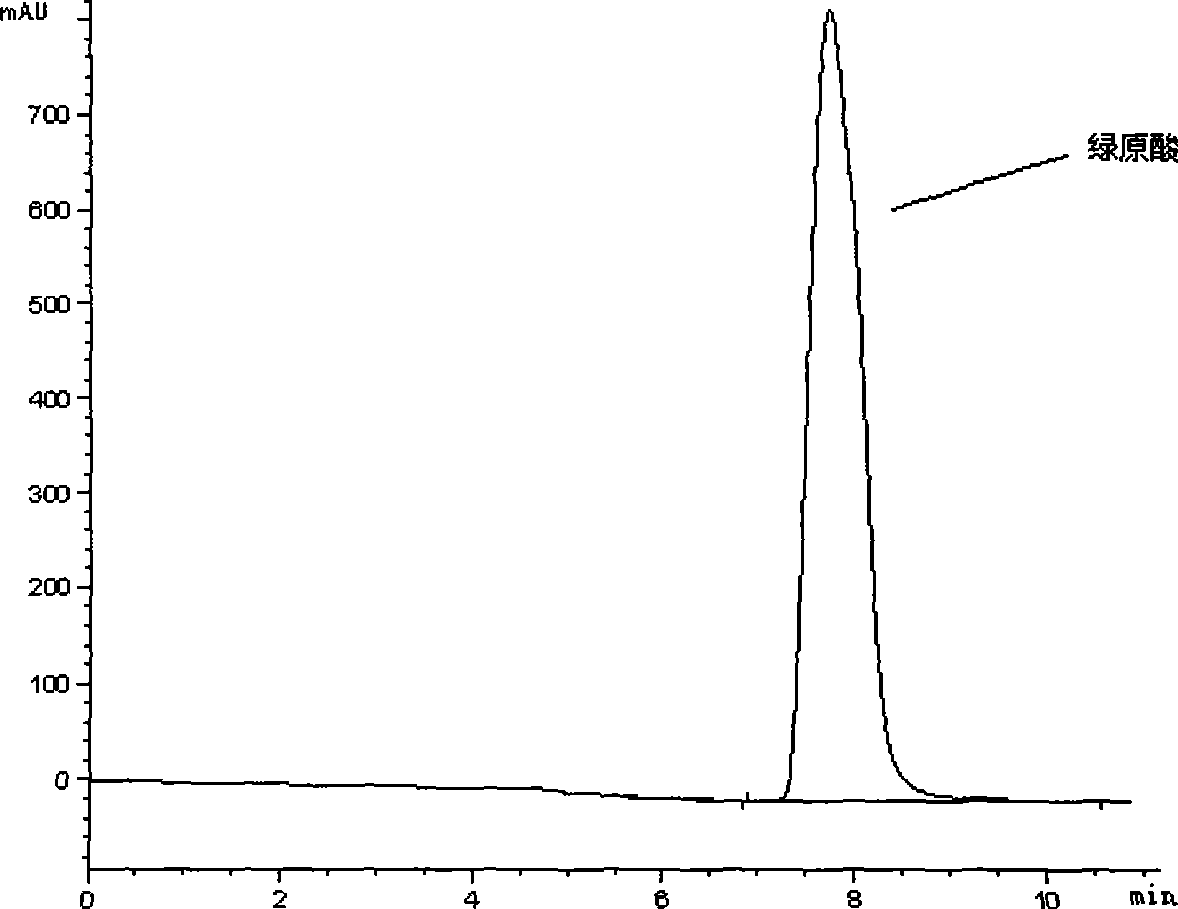

[0036] Thermo company Hypersil ODS C18 (250mm × 4.6mm, 5μm) chromatographic column; mobile phase A is disodium hydrogen phosphate buffer solution (10mmol / L), mobile phase B is methanol; mobile phase ratio is: mobile phase B in 0 ~ 15min Keep 25%; flow rate: 1mL / min; column temperature: 30°C; injection volume: 20μL; detection wavelength 326nm, time 12min.

[0037] Chlorogenic acid standard solution (0.44mg / mL) was injected to obtain image 3 The HPLC figure of each treatment sample; after the filter membrane precision filtration of the leach solution of each treatment sample, the operation of carrying out HPLC determination is the same as that of the standard solution.

[0038] Fix raw materials: the temperature during processing is 100-300°C, and the processing time is 5 seconds to 60 minutes.

[0039] Weigh 1g of solidago powder, add 20mL of water with pH 4.0, and conduct ultrasonic assisted leaching ...

Embodiment 2

[0045] Add the solid-liquid ratio of solid-liquid ratio of 1:20 (W / W) into the ethanol aqueous solution of pH 6.0, ethanol: water 1:5 (W / W), and leaching for 3 hours under the action of microwave. After solid-liquid separation, concentration, separation and purification to obtain refined chlorogenic acid products.

Embodiment 3

[0047] Add the leaves of Solidago japonica treated with solid-liquid ratio 1:4 (W / W) into the ethanol aqueous solution with pH 3.0, ethanol: water-1:0.1 (W / W), and extract under the action of microwave for 6 hours , after solid-liquid separation, the crude extract is passed through an ion exchange column, eluted with water and methanol, and the eluate is concentrated to recover the solvent to obtain the chlorogenic acid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com