Method for smelting low chromium pig iron by utilizing chromium slag

A technology for chromium slag and pig iron, which is applied to the improvement of process efficiency, blast furnace, furnace type and other directions, can solve the problems of reducing the amount of chromium slag produced, difficult to treat chromium slag, and unsatisfactory effect, etc., and achieves the effect of increasing the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with embodiment:

[0034] The method of smelting low-chromium pig iron by using chromium slag, mixing chromium slag, iron ore powder, coke powder and lime, adding water to granulate, granulating into small balls with an average particle size of 1.5-8mm; The sintering machine is sintered into sintered ore, and then the sintered ore is sent to the blast furnace for smelting with chromium ore and coke powder to produce low-chromium pig iron. When smelting in the blast furnace, silica is added according to the situation.

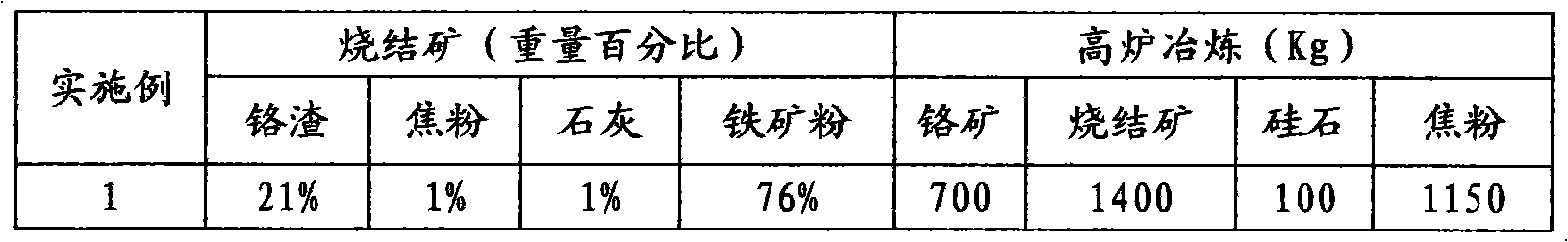

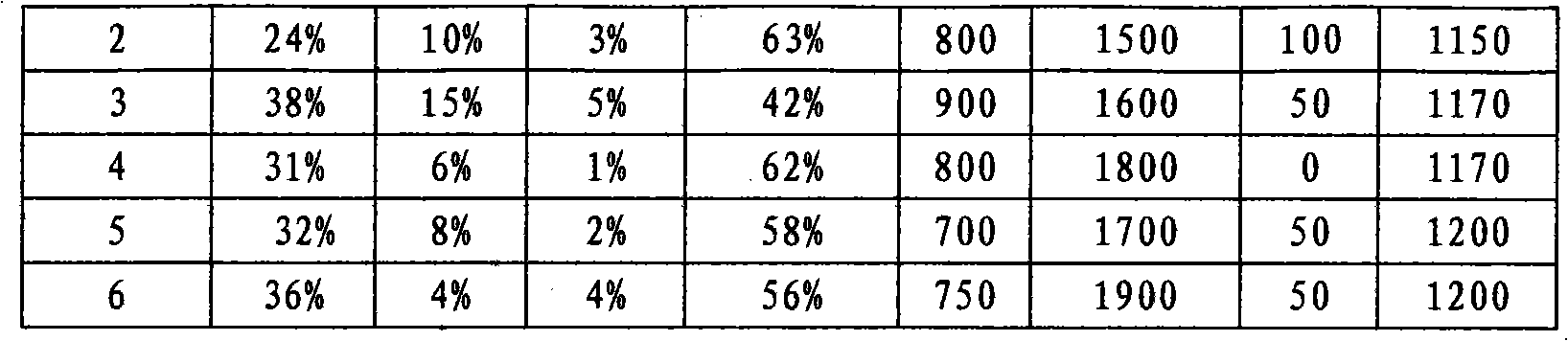

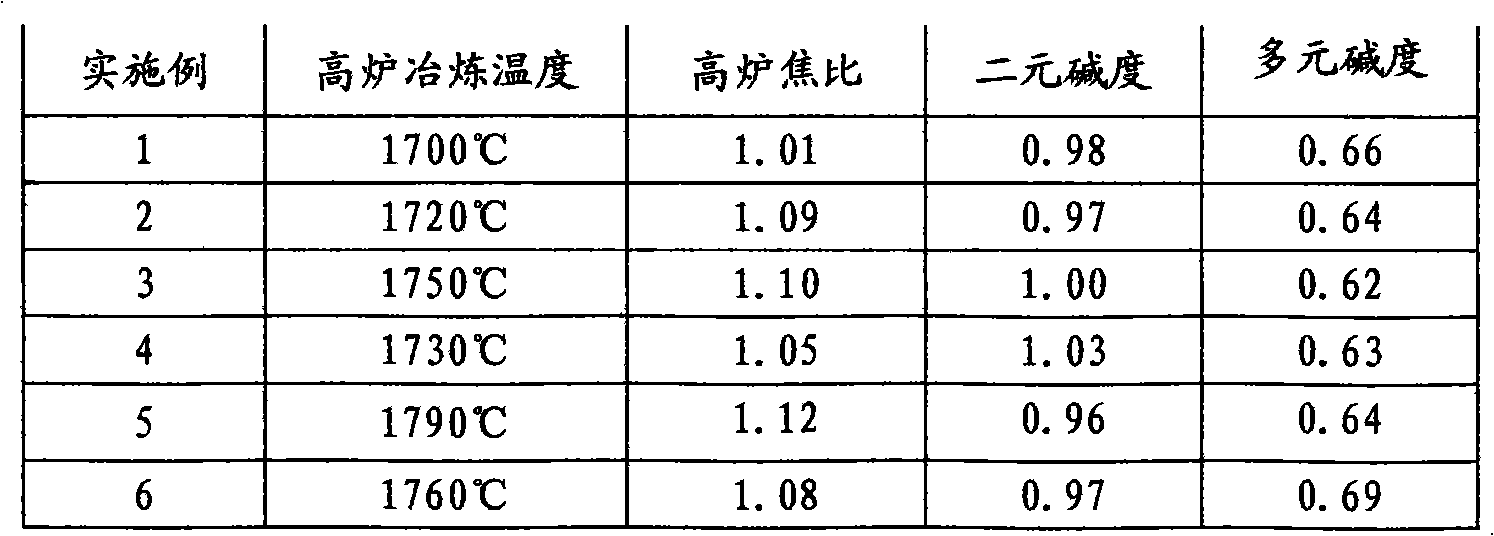

[0035] The weight percent of sinter raw materials in each embodiment and the consumption of each raw material during blast furnace smelting:

[0036]

[0037]

[0038] The average weight percentage of main components of chromium slag:

[0039] Cr 2 o 3

CaO

MgO

Fe

al 2 o 3

SiO 2

Cr 6+

13.54%

9.58%

13.10%

26.12%

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com