Multifunctional intelligent composite gel material as well as preparation method and application thereof

A composite gel, multi-functional technology, applied in medical science, bandages, etc., can solve the problems of poor stretch recovery, no environmental responsiveness, lack of antibacterial properties and tissue viscosity, and inability to effectively use wound dressings, etc., to promote raw materials. Source, promote wound healing, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve calcium chloride and corn starch in water, the mass fractions of the solution are 20% and 13.3%, respectively, heated in a 60℃ water bath for 30 minutes to form a starch-based elastic conductive colloid.

[0042] Dissolve 13% acrylamide in water, add 0.008%, 0.006% and 0.02% N,N'-methylenebisacrylamide, N,N,N',N'-tetramethyl Ethylenediamine and ammonium persulfate are stirred evenly to form a PAM hydrogel precursor.

[0043] The starch-based elastic conductive colloid and the PAM hydrogel precursor are mixed uniformly at a mass ratio of 1:1, and heated in a water bath at 60°C for 30 minutes to form a gel material.

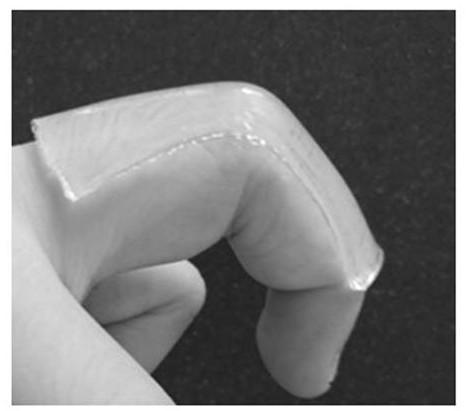

[0044] Place the prepared gel material on the joints of the fingers and perform bending and extension activities at the same time. figure 1 , The results of the morphology of the gel material prepared in this example and the fit of the skin at the joints show the photos, by figure 1 It can be seen that the gel material has a good fit with the skin at the j...

Embodiment 2

[0049] Dissolve copper nitrate and sweet potato starch in water with a mass fraction of 10% and 18%, respectively, and heat in a water bath at 80 ℃ to form a starch-based elastic conductive colloid.

[0050] Dissolve 15% mass fraction of acrylamide in water, add 0.008% and 0.02% N,N'-methylenebisacrylamide and sodium persulfate, stir evenly to form PAM hydrogel precursor .

[0051] The prepared starch-based elastic conductive colloid and PAM hydrogel precursor were mixed uniformly at a mass ratio of 1:2, and heated in a water bath at 60 ℃ for 30 min to form a gel material.

[0052] The direct contact method was used to test the antibacterial properties of the gel material. The formula for calculating the antibacterial rate is as follows:

[0053] ,

[0054] In the formula: R is the antibacterial rate (%); A is the average number of bacteria planted on the surface of the tested bacteria (CFU / mL); B is the average number of bacteria (CFU / mL) after the test sample has been in contact wi...

Embodiment 3

[0057] Dissolve calcium chloride and strontium nitrate in water according to the mass ratio of 5% and 10% of the solution, then add corn starch with a mass fraction of 20%, and heat it in a 60 ℃ water bath to form a starch-based elastic conductive colloid. Add 5 mL with a mass fraction of 0.1 % Bromophenol blue solution, stir evenly to simulate drug release.

[0058] Dissolve 15% acrylamide in water, add 0.006% and 0.01% N,N-N,N'-methylenebisacrylamide and ammonium persulfate, and mix well to form PAM water Gel precursor.

[0059] The prepared starch-based elastic conductive colloid and PAM hydrogel precursor were mixed uniformly at a mass ratio of 2:1, and heated in a water bath at 80 ℃ for 60 min to form a gel material.

[0060] The gel material was made into a cube with an area of 1 cm*1 cm and a thickness of 1 mm, which was placed in deionized water, and the release of bromophenol blue in the dressing was tested with a microplate reader at regular intervals. The experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com