Method for preparing chlorogenic acid by using Jerusalem artichoke

A technology of chlorogenic acid and Jerusalem artichoke, which is applied in the field of separation and purification of biochemical products, can solve the problems of high price of chlorogenic acid products, difficulty in separation and purification, and strong infectivity, so as to improve the yield of chlorogenic acid and be economical. Benefits and social benefits, the effect of shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

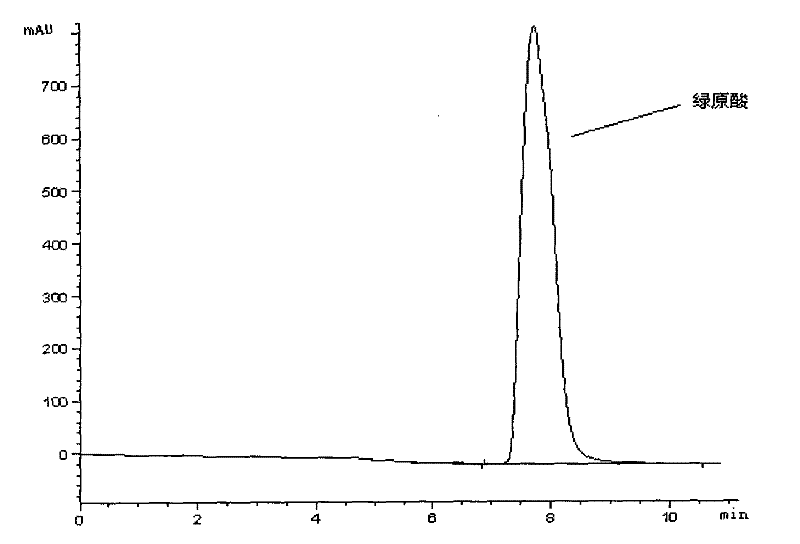

Image

Examples

Embodiment 1

[0037] Raw material fixation treatment: temperature 100-300°C, treatment time 5 seconds to 60 minutes.

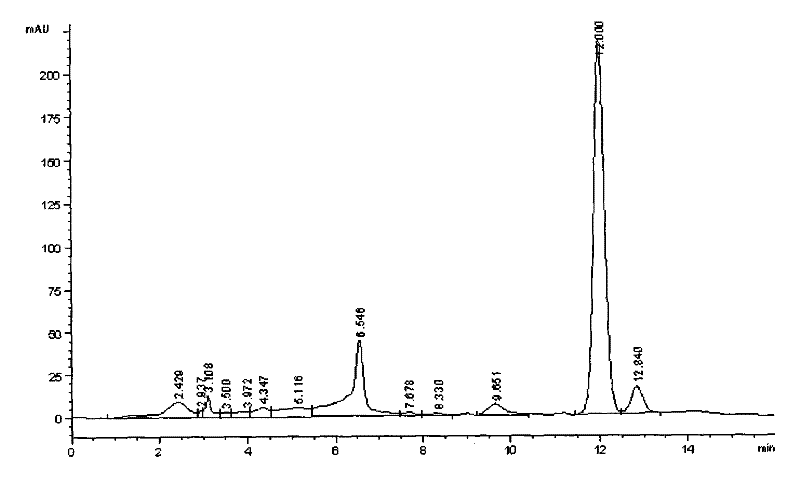

[0038] Weigh 1.0 g of Jerusalem artichoke powder (passed through a 40 mesh sieve) and add 20 mL of distilled water with pH 4.0, leaching with ultrasonic assistance at 50°C for 40 minutes, filter, collect the filtrate, and re-extract the residue with 20 mL of distilled water with pH 4.0 40min. The filtrate was collected by filtration again. The two filtrates were combined, and finally the filtrate was adjusted to 50 mL. The extract was analyzed by HPLC, and the results were as follows: Figure 4 shown;

Embodiment 2

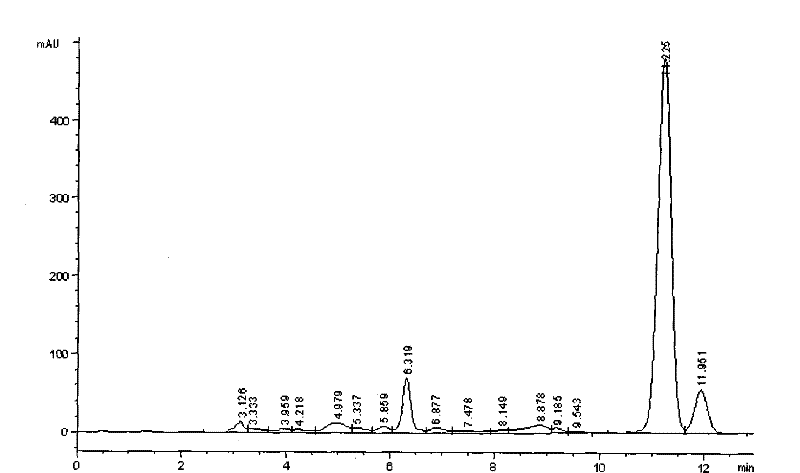

[0041] Add Jerusalem artichoke leaves into methanol aqueous solution with a pH of 4.0 and methanol:water 1:1.5 at a solid-to-liquid ratio of 1:20 (W / W), leaching with ultrasonic assistance at 50°C for 2 hours, and filtering the obtained solution is the crude extraction of chlorogenic acid. liquid. Concentrate the obtained extract by rotary evaporation to a volume of 5-10 mL after concentration, and collect it for later use.

[0042] Weigh 6.0 g of polyamide and pack it into a column by wet method (column size 1.5 cm×28.0 cm). The concentrated sample after extraction was separated by polyamide column, eluted with 10% ethanol, and the eluate fraction with higher content of chlorogenic acid was collected, and the ethanol was removed by rotary evaporation. After drying, the product was recrystallized from ethyl acetate. After the crystals appear, pour off the mother liquor to obtain a pure product with a chlorogenic acid content of 93%. The mother liquor can be recycled. The c...

Embodiment 3

[0044] Add the leaves of Jerusalem artichoke to a methanol aqueous solution with a pH of 4.0 and methanol:water 1:1 at a solid-to-liquid ratio of 1:25 (W / W), leaching with ultrasonic assistance at 50°C for 3 hours, and after solid-liquid separation, rotary evaporation to obtain concentrated liquid for use.

[0045] Weigh 16.0 g of macroporous resin, treat it according to the conventional pretreatment method, and then pack it into a column by wet method (column size 1.5 cm×28.0 cm). The concentrated solution after extraction was separated by column, and the adsorbed saturated resin was eluted with 40% ethanol, and the eluate components with higher chlorogenic acid content were collected, and the ethanol was removed by rotary evaporation. Finally, the product was recrystallized from ethyl acetate. After the crystals appear, the mother liquor can be poured out to obtain the refined chlorogenic acid product. Product purity can reach more than 90%. The mother liquor can be recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com