Middle-density fibre board and its production method

A production method and fiberboard technology, which are applied to medium density fiberboard and its production field, can solve the problems of forest resources and ecological environmental protection, damage and other problems, and achieve the effects of forest resources and ecological environmental protection, saving wood resources, and cheap raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

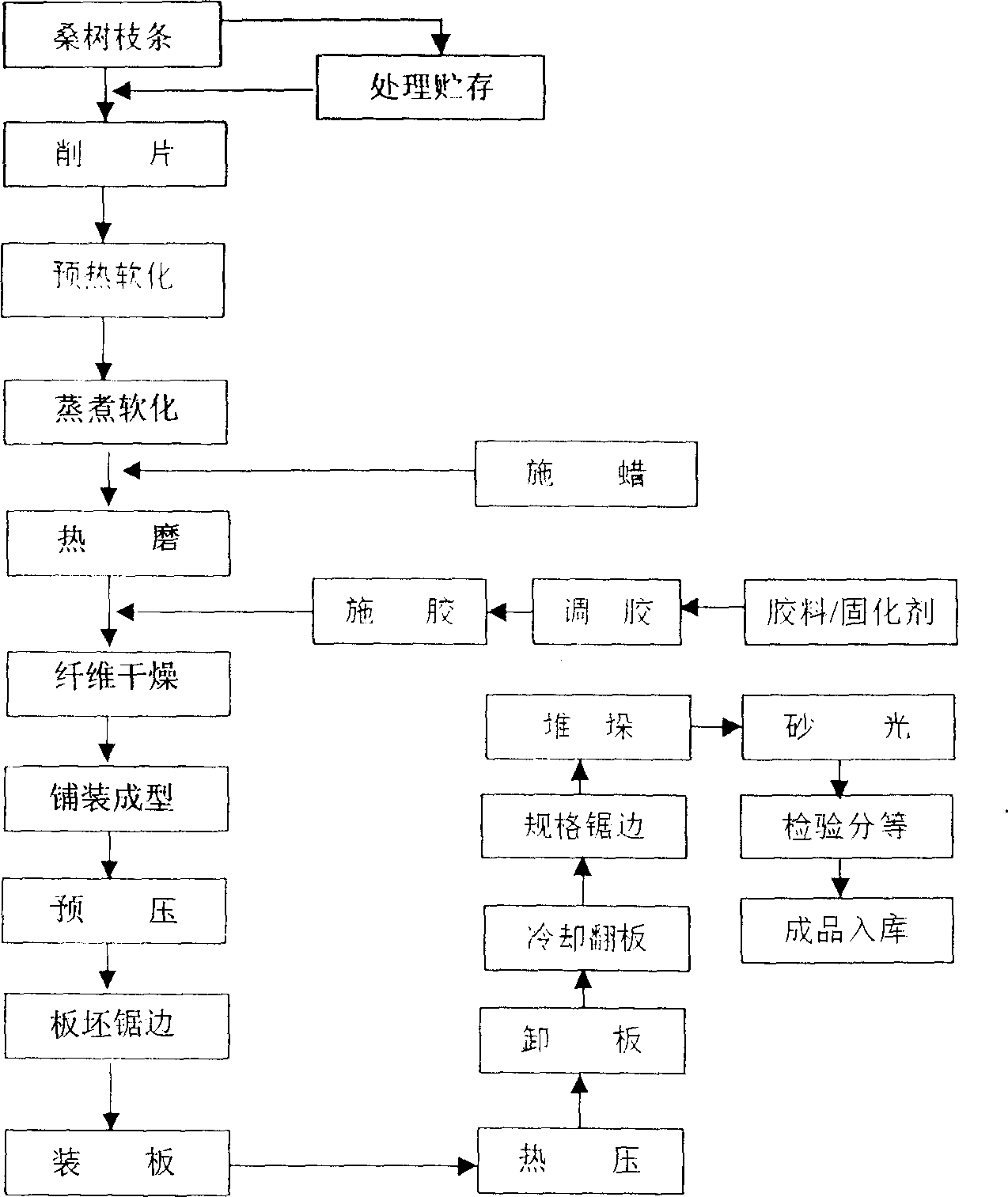

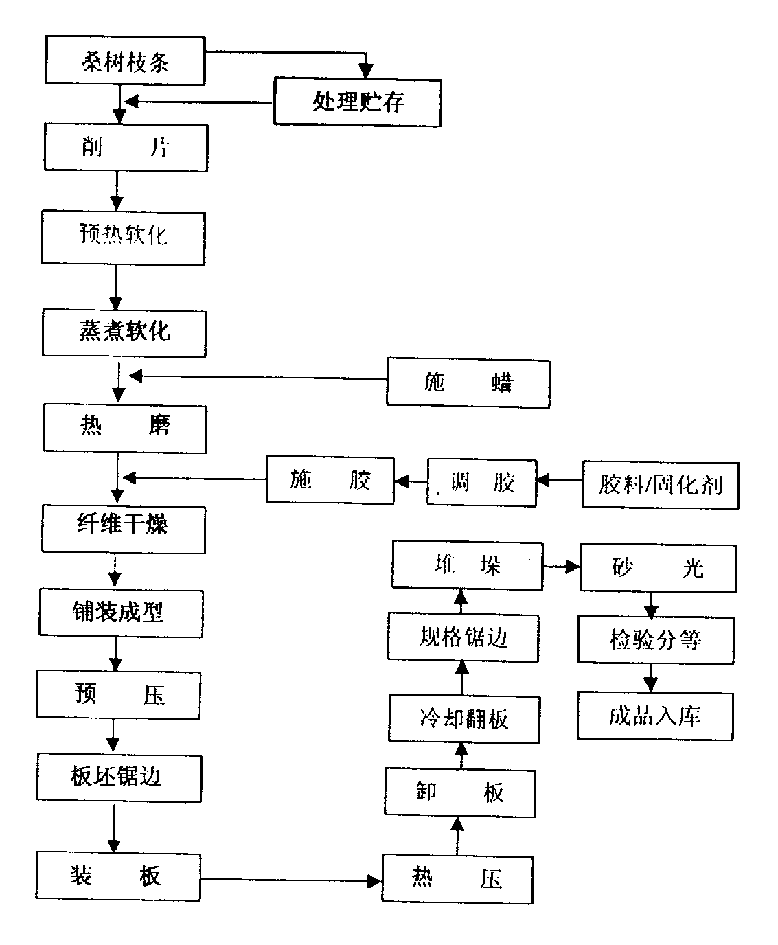

[0017] Such as figure 1 As shown, 12mm thick mulberry branch medium density fiberboard is processed and produced by the following steps:

[0018] 1. Handle and store the raw materials of mulberry branches. Since the mulberry branches are all cut during the growing season of mulberry trees from May to June, the content of polypentose, hot water lysate and protein in the branches is high, and the cut mulberry branches are very susceptible to fungal erosion and rot and insects, so the mulberry branches must be dried in the sun after cutting, and then stacked in a sheltered and ventilated place. When the stacking storage period is longer (more than 3 months), it can be sprayed with a mixture of 10% Baidu fungicide and 50% chrysanthemum insecticide or wood anti-mold preservative (such as 3% CH anti-mold) Processing can also adopt the storage method of bagging after peeling or shaving the mulberry strips, so as to ensure the supply of raw materials for the production line througho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com