Novel solid wood multilayer veneer panel and production method thereof

A veneer and solid wood technology, applied in the direction of layered products, wood layered products, wooden veneer joints, etc., can solve the problems of raw material consumption, manpower, waste of material resources, high cost, etc., to reduce the rate of defective products, increase Impact resistance, the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

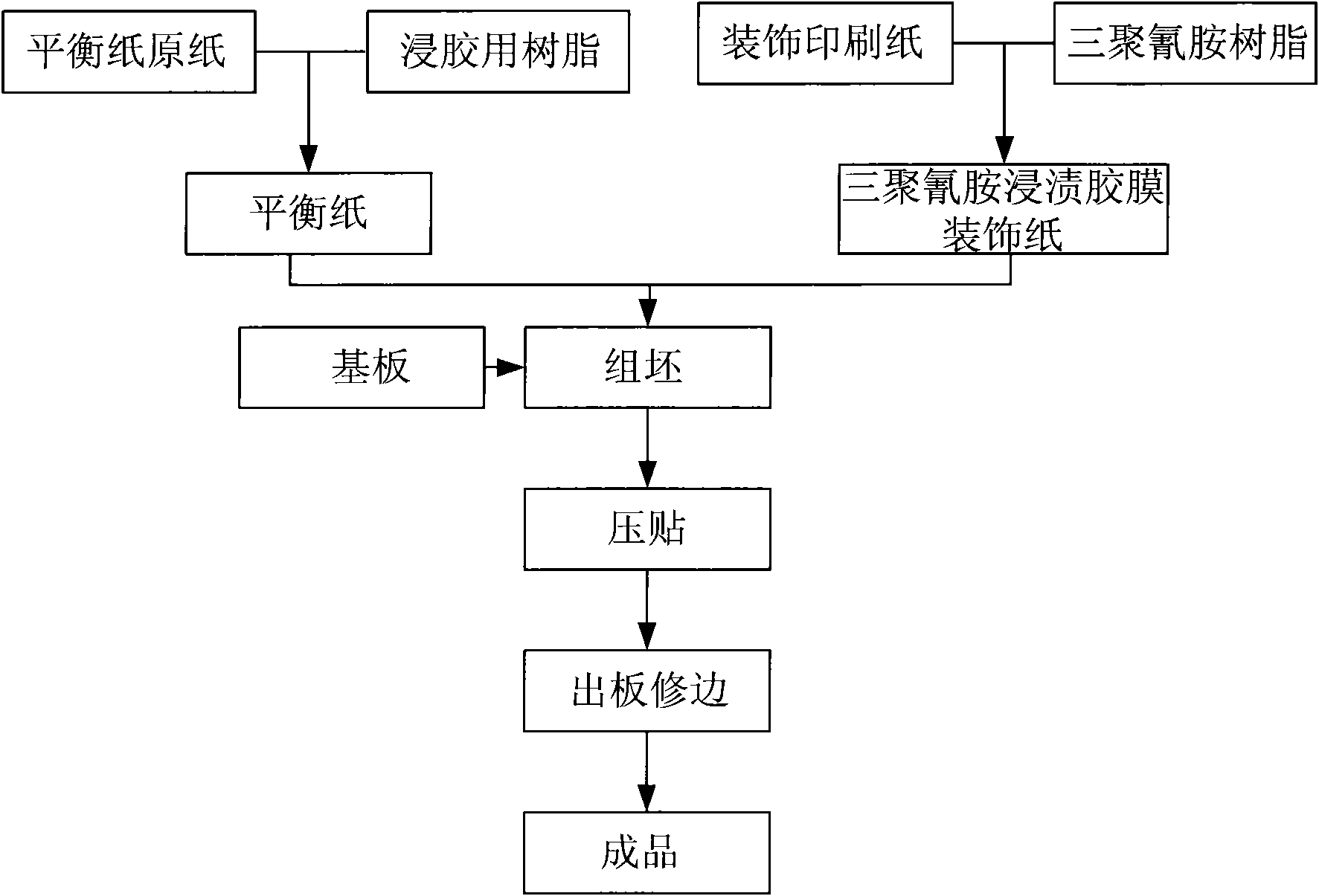

Method used

Image

Examples

Embodiment 1

[0023] Assemble the steel plate and buffer pad into the laminating machine, select particle board as the substrate, wipe off dust, wood chips and other objects on its surface, cover the balance paper and melamine-impregnated film decoration paper on the substrate in turn, and make the melamine-impregnated film decoration The paper and the balance paper basically overlap to ensure that the balance paper completely covers the surface of the substrate, raise the temperature, and send the substrate covered with the balance paper and melamine-impregnated adhesive film decorative paper into the laminating machine, and ensure that the center line of the substrate and the center line of the press Coincidence; close the press, start pressing, the pressing time is 20 minutes, the hot pressing temperature is 90°C, and the hot pressing pressure is 400kg / cm 2 , and then take it out from between the upper and lower templates of the hydraulic press, and the operator cuts off the remaining edg...

Embodiment 2

[0025] Assemble the steel plate and buffer pad into the laminating machine, select medium density fiberboard as the substrate, wipe off dust, sawdust, etc. The film decorative paper and the balance paper are basically overlapped to ensure that the balance paper completely covers the surface of the substrate, raise the temperature, and send the substrate covered with the balance paper and melamine-impregnated film decoration paper into the laminating machine, and ensure that the center line of the substrate is in line with the press. The center line coincides; close the press and start pressing, the pressing time is 1 minute, the hot pressing temperature is 200°C, and the hot pressing pressure is 600kg / cm 2 , and then take it out from between the upper and lower templates of the hydraulic press, cut off the remaining edges with a knife by the operator, and place it flat indoors to dry naturally for 55 hours; then it can be inspected and packaged to obtain the static structure of...

Embodiment 3

[0027] Assemble the steel plate and buffer pad into the laminating machine, select a three-layer layered structure multilayer board as the substrate, wipe off dust, sawdust, etc. on the surface, and cover the balance paper and melamine-impregnated film decorative paper on the substrate in turn , so that the melamine-impregnated decorative paper and the balance paper are basically overlapped to ensure that the balance paper completely covers the surface of the substrate, raise the temperature, and send the substrate covered with the balance paper and the melamine-impregnated decorative paper into the laminating machine, and ensure that the substrate The center line coincides with the center line of the press; close the press, start pressing, the pressing time is 10 minutes, the hot pressing temperature is 130°C, and the hot pressing pressure is 200kg / cm 2 , and then take it out from between the upper and lower templates of the hydraulic press, cut off the remaining edges with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com