Special veneering pressing and sticking method of melamine impregnated paper

A melamine and special-shaped technology, which is applied to chemical instruments and methods, surface covering paper, door leaves, etc., to achieve the effect of high surface hardness, good chemical resistance, and increased aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

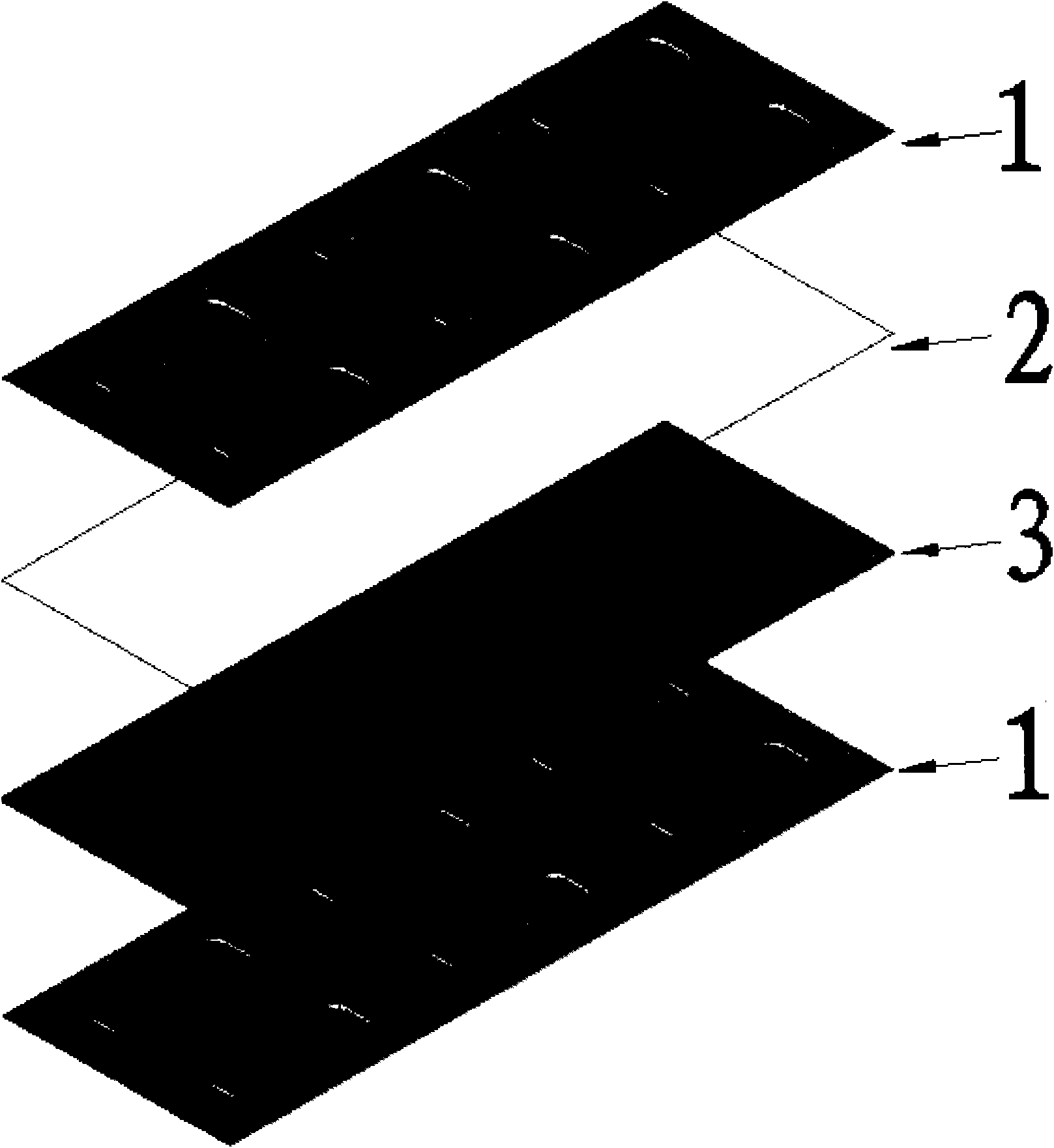

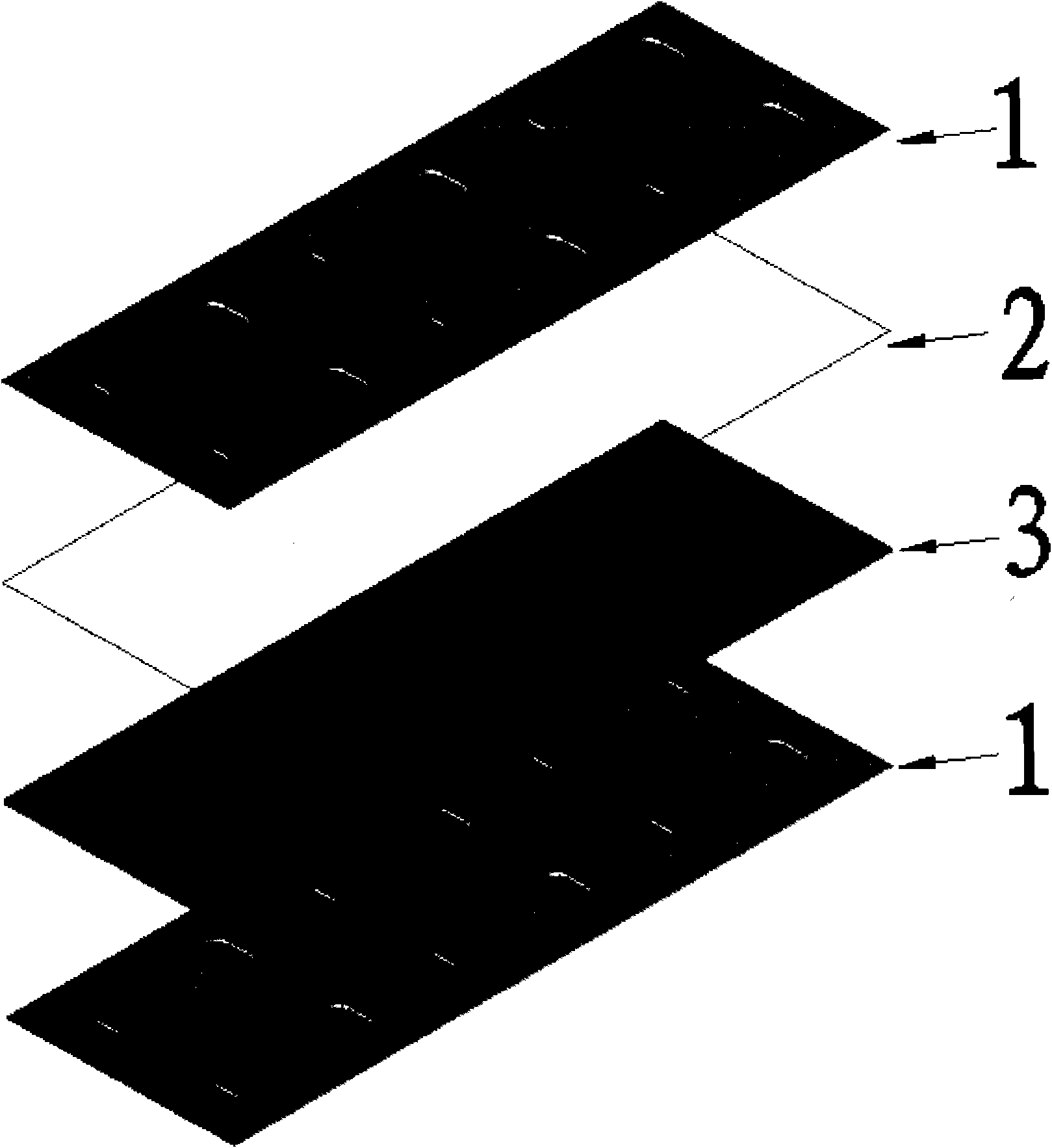

[0034] like figure 1 As shown, the hard miscellaneous wood and poplar (or pine) are cut into wood chips respectively; the wood chips are softened in vacuum for 3-4 minutes at a temperature of 160-170 ° C and a pressure of 7-8 kg to obtain softened wood chips. Select the appropriate grinding disc of the corresponding tooth type of the thermal grinding machine to ensure that the diameter of the wood fiber fineness is controlled at 0.04mm, and the length of the wood fiber is 4mm; the adhesive is 200kg / m 3 , paraffin: 5kg / m 3 , softener Release agent and surface sealant for external use, dilution ratio: 95 parts of demineralized water diluted with 5 parts of softener, the amount added is about 8g / m 2 , through a continuous hot press machine to obtain softened medium density fiberboard 3; the decorative paper is impregnated with 30% of formaldehyde solution, 35% of methanol solution, 25% of melamine, 3% of edible pure ethanol with a concentration of 40-50%, and urea 1%, the mix...

Embodiment 2

[0036] like figure 1 As shown, the hard miscellaneous wood and poplar (or pine) are cut into wood chips respectively; under the condition of temperature of 160-170 ° C and pressure of 7-8 kg, the softened wood chips are obtained by vacuum softening for 3-4 minutes. Appropriate grinding discs of the corresponding tooth type of the thermal grinding machine, to ensure that the diameter of the wood fiber fineness is controlled at 0.05mm, and the length of the wood fiber is 3mm; the adhesive is 210kg / m 3 , Paraffin: 6kg / m 3 , softener Release agent and surface sealant for external use, dilution ratio: 90 parts of demineralized water diluted with 10 parts of softener, adding about 5g / m 2 , a continuous press to obtain softened MDF 3; the softened MDF 3 is softened twice using a specially prepared softener; wherein the softener (ammonia) formula is: the ammonia concentration is 7% (ammonia-containing 63%) ammonia solution, pH value: 4-5, thermal decomposition temperature of the s...

Embodiment 3

[0038] like figure 1 As shown, the hard miscellaneous wood and poplar (or pine) are respectively cut into wood chips; at a temperature of 160-170 ° C and a pressure of 7-8 kg, vacuum softening for 3-4 minutes to obtain softened wood chips; by selecting Appropriate grinding discs of the corresponding tooth type of the thermal grinding machine, to ensure that the diameter of the wood fiber fineness is controlled at 0.04mm, and the length of the wood fiber is 4mm; the adhesive is 200kg / m 3 , paraffin: 5kg / m 3 , softener Release agent and surface sealant for external use, dilution ratio: 95 parts of demineralized water diluted with 5 parts of softener, the amount added is about 8g / m 2 , a continuous press to obtain softened medium density fiberboard 3; decorative paper (gram weight is 80g / m 2 base paper) soaked with 30% formaldehyde solution, 35% methanol solution, 25% melamine, 3% edible pure ethanol with a concentration of 40-50%, 1% urea, 0.1% sodium hydroxide solution, 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com