Bamboo-made wallboard

A technology of wall panels and bamboo tubes, which is applied in the field of construction and decoration materials, can solve the problems of heavy weight of bamboo panels, laborious processing, high price, etc., and achieve the effects of low price, convenient construction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

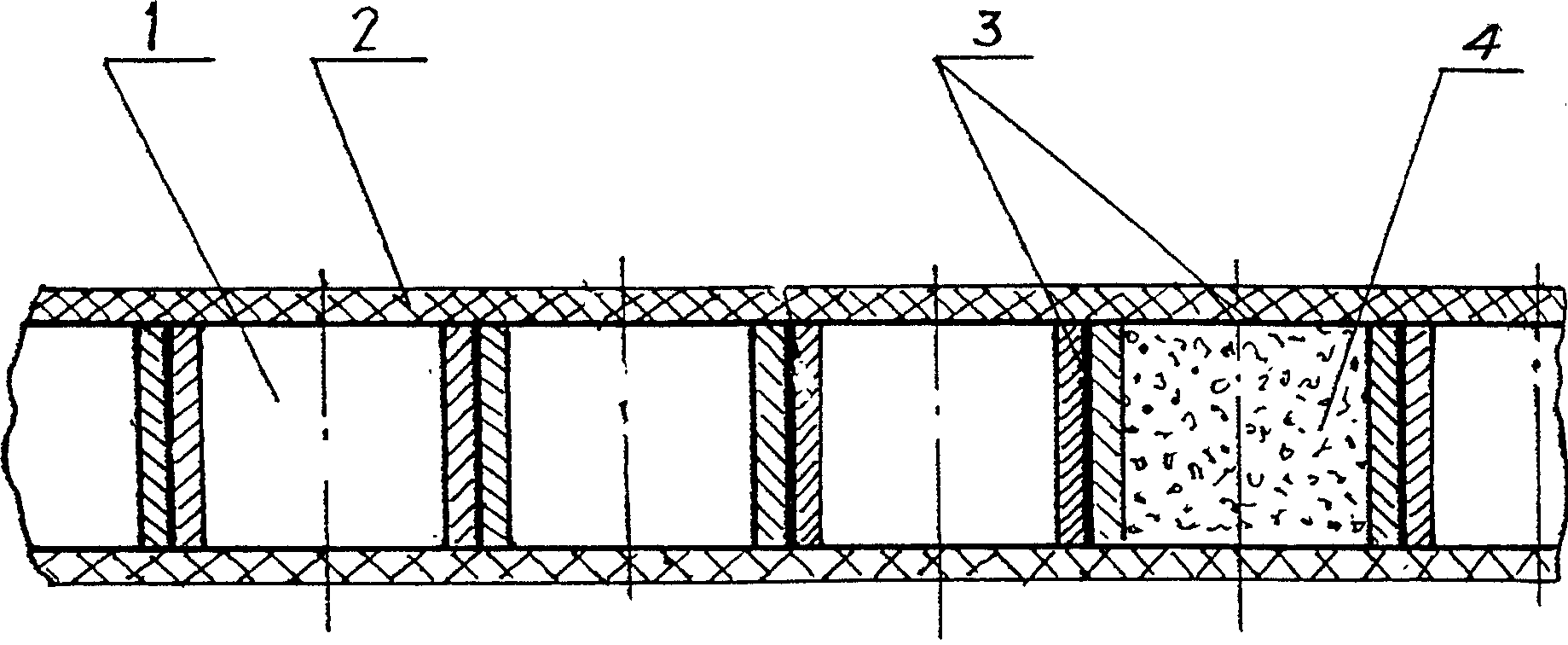

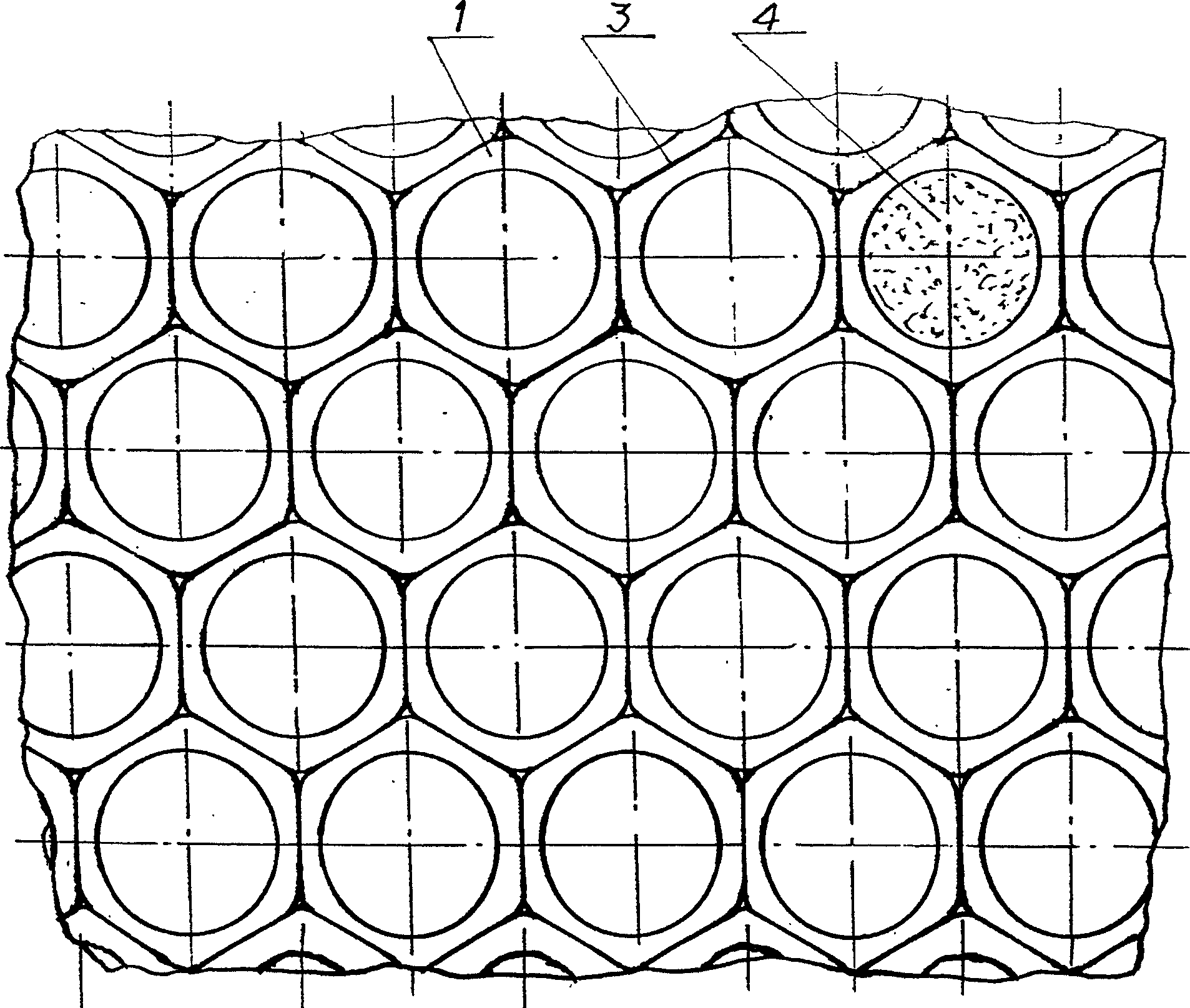

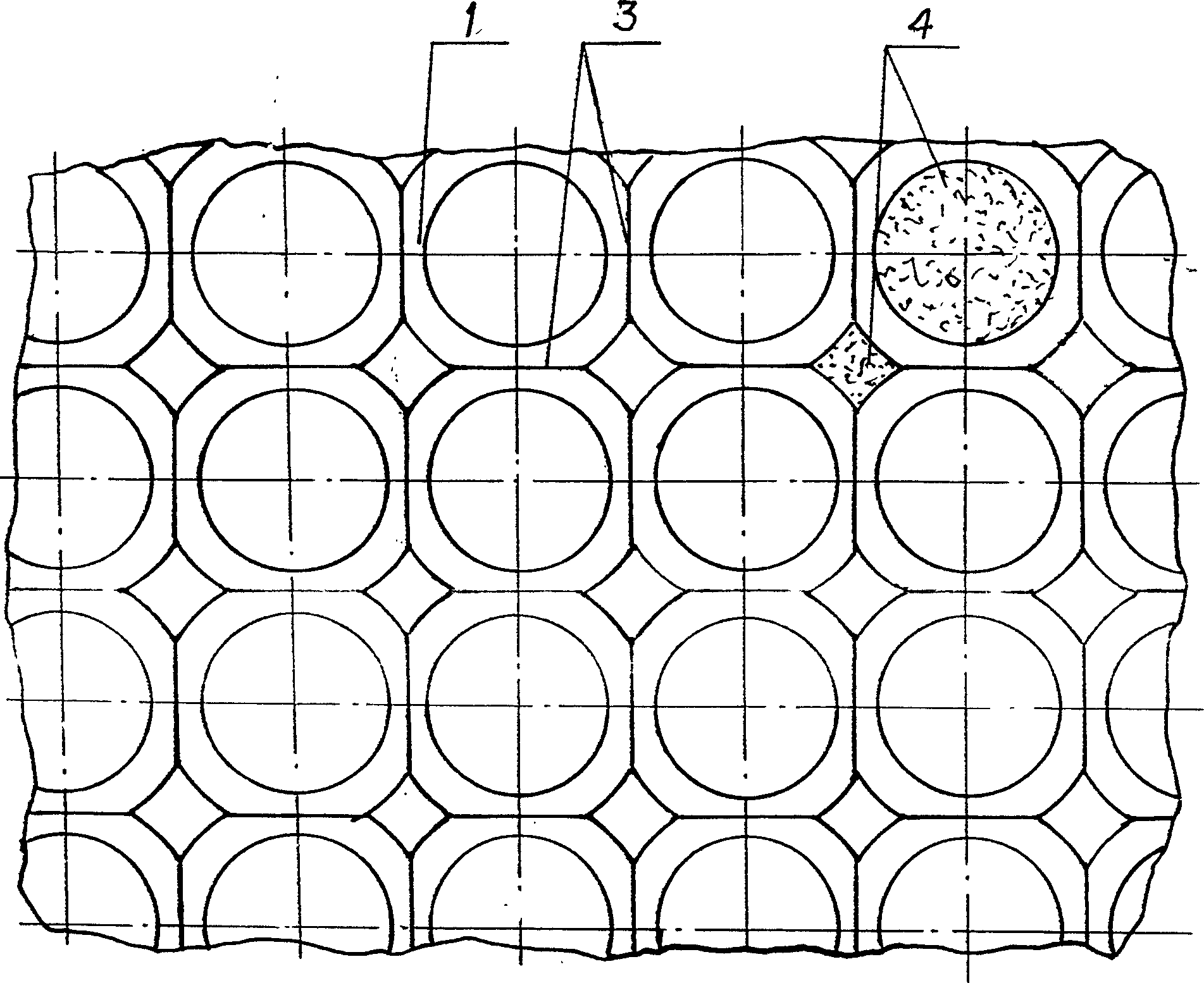

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: figure 1 A cutaway view showing a bamboo wall panel. figure 2 Diagram showing the arrangement of hexagonal bamboo tubes for bamboo wall panels. image 3 Diagram showing the arrangement of square bamboo tubes for bamboo wall panels. Figure 4 Diagram of arrangement of circular bamboo tubes representing bamboo wall panels.

[0019] The bamboo wallboard is composed of bamboo tubes 1 whose outer peripheral surfaces are bonded to each other. There is an adhesive 3 for connecting the bamboo tubes at the contact point of the outer peripheral surfaces of the bamboo tubes 1. The adhesive 3 will bond a plurality of closely arranged bamboo tubes 1 into a plate shape. 1 is a cylindrical shape with a hole in the middle. In order to facilitate bonding, the shapes of a plurality of bamboo tubes 1 should be the same. The close arrangement of shapes makes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com