High-intensity shaving board and manufacturing method thereof

A particleboard, high-strength technology, applied in the manufacture of high-strength particleboard, in the field of high-strength particleboard, to achieve the effect of low density, protection of ecological environment, and good load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

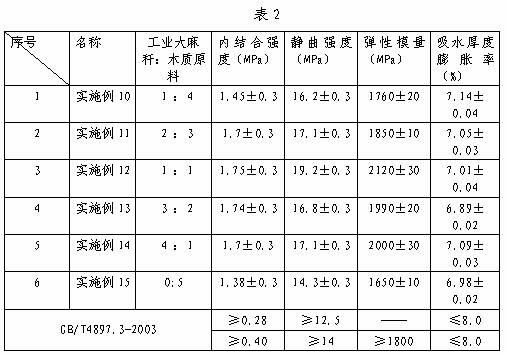

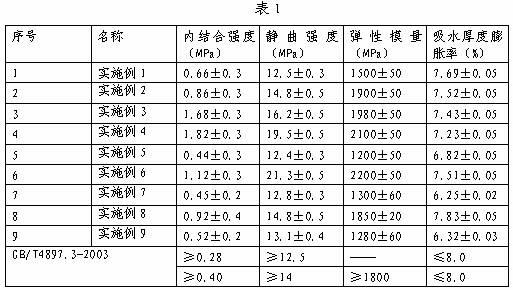

[0024] Example 1 Preparation of pure industrial hemp stalk particleboard

[0025] The industrial hemp stalk waste is used as the raw material for the board. It has been determined that the moisture content of the industrial hemp stalk raw material is 15-18%, and the raw material is humidified to control its moisture content to 40%. Use a chipper to make raw materials into fragments with a length of 5-10mm, and then use a double-drum planer to further crush the raw materials to obtain shavings with a length of 3-8mm, a width of 2-4mm, and a thickness of 2-4mm, and use A vibrating sieve removes oversized shavings. Use a single-channel dryer to dry the industrial hemp stalk shavings at 140°C until the moisture content is 3-5%. Apply a urea-formaldehyde resin adhesive to the dried industrial hemp shavings by using a spray glue sprayer, the solid content of the adhesive is 60-65%, and the sizing amount is 8% of the absolute dry weight of the industrial hemp shavings, and at the s...

Embodiment 2

[0027] Repeat Example 1, with the following differences: 10% shaving sizing amount, and the test results are shown in Table 1.

Embodiment 3

[0029] Repeat Example 1, with the following differences: 12% shaving sizing amount, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com