Water and energy saving domestic animal fermentation bed and preparation method thereof

A fermentation bed and fermentation bed bacterial strain technology, which is applied in poultry farming, animal husbandry, animal houses, etc., can solve the problems of litter heat stress, litter waste, large water consumption, etc., to reduce thickness, Effects of reducing costs and alleviating summer heat stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1 Test materials and methods

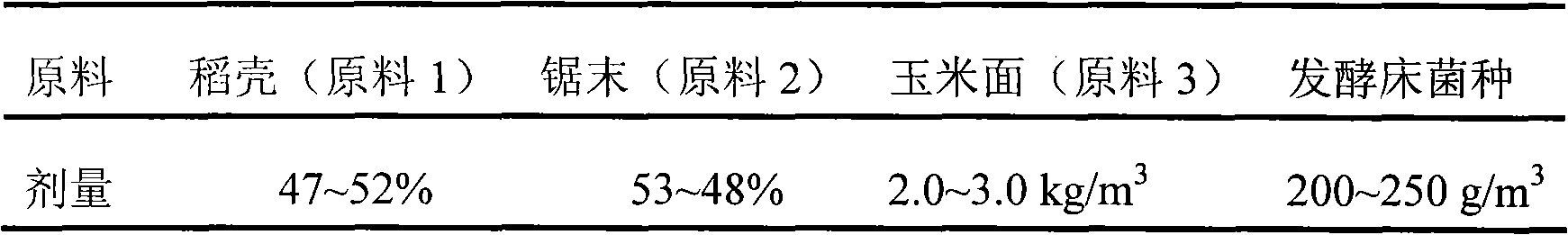

[0017] 1.1 Test materials

[0018] Broiler chicken fry and broiler feed are provided by Shandong Chunxue Food Co., Ltd.

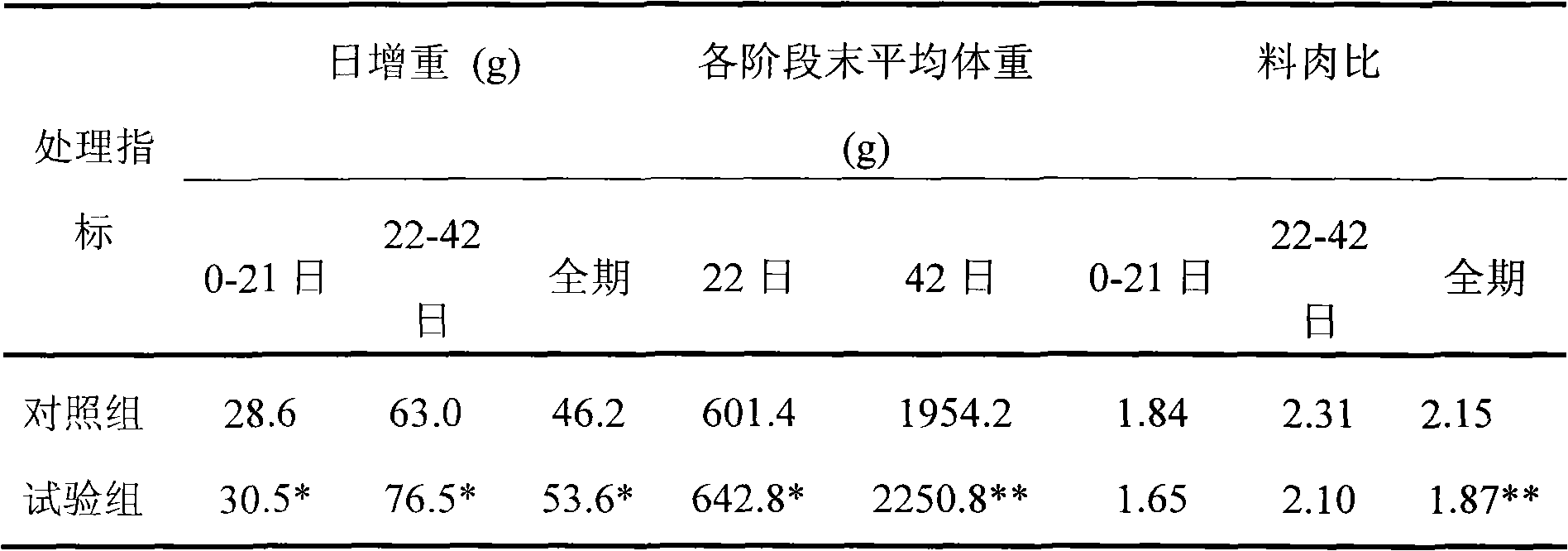

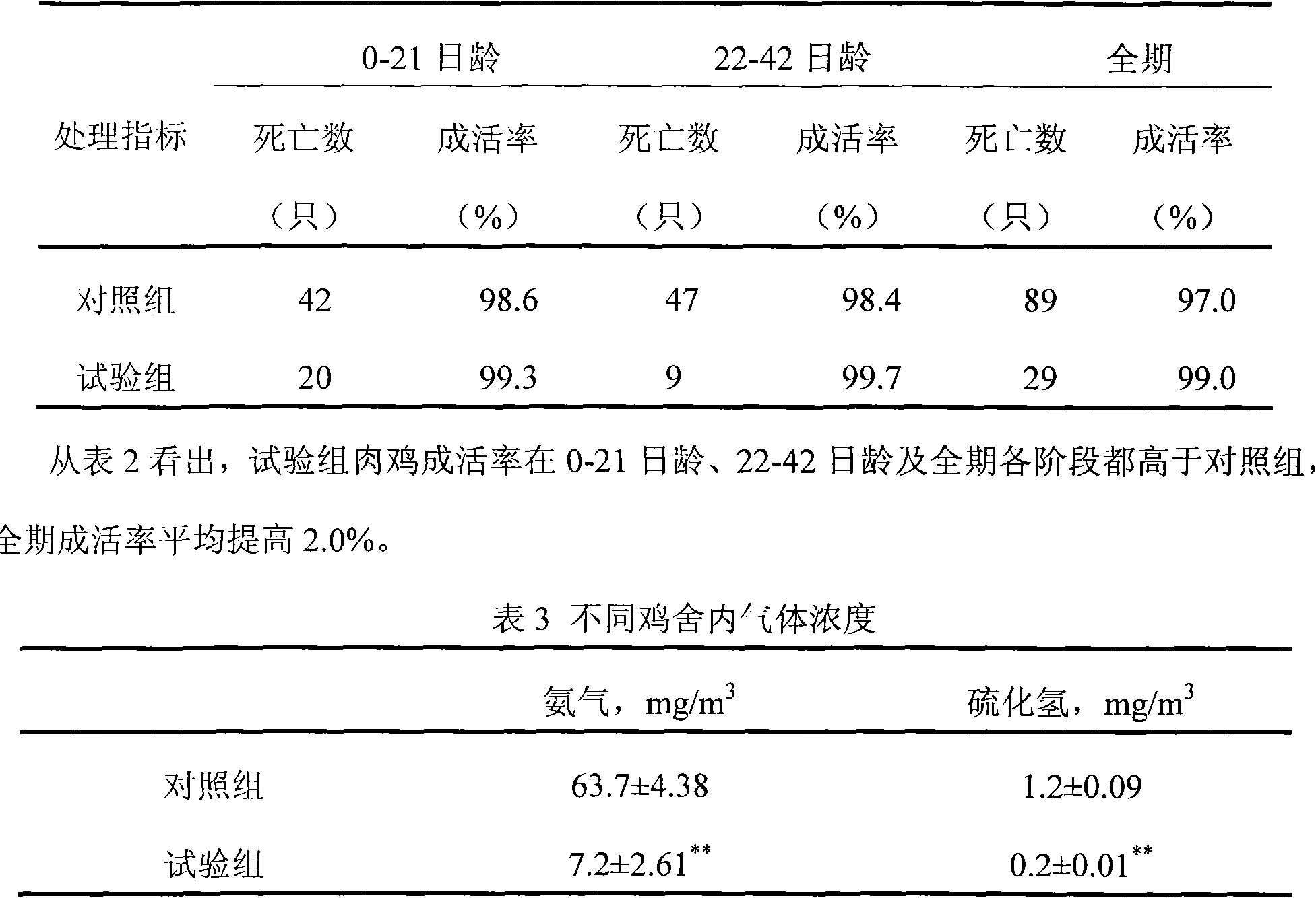

[0019] 1.2 Experimental animals and grouping

[0020] Six thousand one-day-old healthy commercial chicken seedlings were randomly divided into two groups, the control group and the test group, each with 3000 chickens. The control group was reared in a plastic greenhouse with soil-sand bedding, and the experimental group was reared in a plastic greenhouse with water-saving and labor-saving broiler fermentation beds. The entire experiment was raised by the same person, and the feeding management procedures were consistent with the epidemic prevention procedures. Immunization is carried out in accordance with the broiler epidemic prevention procedures specified by the company. The immunization procedures are as follows: 7-day-old for the first immunization of Newcastle disease attenuated vaccine, 14-day-old for drinking water im...

Embodiment 2

[0039] Tai'an Broiler Breeder Factory began to raise broiler breeders on the fermentation bed on September 22, 2009. The area of the broiler breeder fermentation bed is 300 square meters, and the thickness of the fermentation mattress material is 32 cm. The quality of dried distiller’s grains, sawdust, bran, and fermentation bed strains are qualified, and the addition ratios are 52%, 48%, and 2.1kg / m respectively. 3 And 210g / m 3 . First prepare the dried vinasse, sawdust, bran and fermentation bed bacteria. The quality of distiller’s grains, sawdust, and bran are qualified, without mold and chemical additives, and the content of bacillus in the fermentation bed bacteria is 3×1.0 7 Pieces / g. Mix the bran with the fermentation bed bacteria. Lay the sawdust on the ground, the thickness of the sawdust bedding is 15.4cm, and the bedding area is 300 square meters. Spread the mixture of bran and fermentation bed bacteria on the sawdust layer. Then spread the vinasse on the mixtu...

Embodiment 3

[0041] 1Materials and methods

[0042] 1.1 Experimental animals and materials

[0043] 6200 cherry valley meat duck seedlings were selected and tested at Songzhuang meat duck farm in Laiwu. The start time was March 15, 2009, and the test duration was 37 days.

[0044] 1.2 Experimental design

[0045] 6200 ducklings were randomly divided into control group and test group, 3100 in each group, raised in 300 square meters of straw bedding duck house and water-saving fermentation bed house. The thickness of straw bedding is 25cm. The bedding thickness of the water-saving and labor-saving fermented mattress material is 25cm. The raw materials of the fermented mattress material are peanut shells, sawdust, secondary powder and fermentation bed bacteria, and the proportions are 48%, 52%, 2.5kg / m 3 , 200g / m 3 . The method of making the fermentation bed is to mix the secondary powder and the fermentation bed bacteria, and then spread the 13cm thick sawdust on the bottom of the fermentation bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com