Process of producing bamboo chipboard

A manufacturing method and technology for large pieces of bamboo are applied in the direction of manufacturing tools, flat products, pretreatment of molding materials, etc., to achieve the effects of reducing the cost of raw materials and production costs of bamboo materials, reducing production costs, and being highly adaptable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

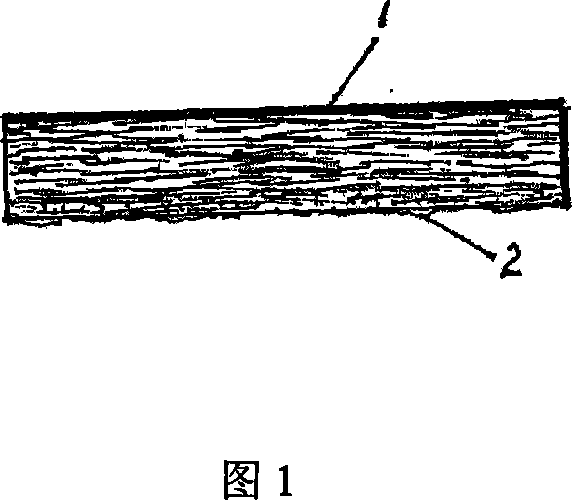

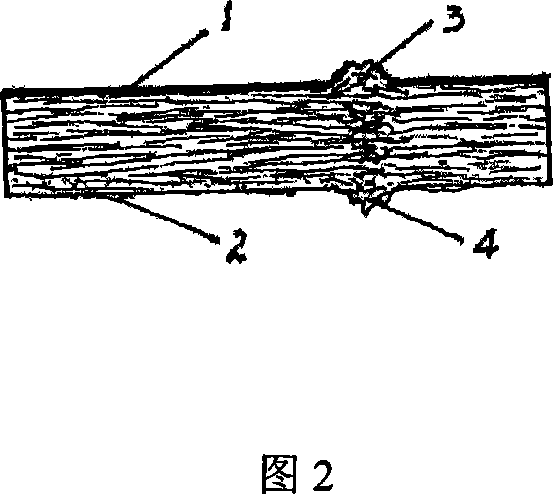

[0047] Use dragon bamboo to grow more than 2 years old, cut the bamboo stalks into 70mm long bamboo tubes, and cut the bamboo tubes into 0.5±0.1mm thick bamboo shavings along the longitudinal diameter plane (see Figure 1 or Figure 2). The large bamboo shavings are placed in a drum dryer and dried to a moisture content of 7%, and a drum mixer is used for spray sizing with 10% melamine-modified urea-formaldehyde resin. The large pieces of wood shavings after sizing are dried to a moisture content of 8%. According to the relationship between the density of Longzhu, the average density of Longzhu board and the target performance, the target density is set to 0.763g / cm 3 It is converted into a paving amount of glue-containing shavings per unit area, and paves it into a single-layer random structure slab (as shown in Figure 7) according to the uncertain axis angle β of the shavings. , Set the hot pressing temperature to 140℃, the hot pressing pressure to 3.6Mpa, and the hot pressing tim...

Embodiment 2

[0049] Repeat Example 1, with the following differences: Choose moso bamboos that are more than 2 years old, cut them into long thin bamboo strips with a thickness of 0.6±0.1mm along the longitudinal direction of the bamboo stalks with a slicing machine, and then cut them with a cutting machine Large pieces of bamboo shavings with a length of 120mm. Phenolic resin is used for spray sizing at a ratio of 7%, and the target density is set to 0.726g / cm according to the relationship between the density of moso bamboo itself, the average density of moso bamboo board and the target performance. 3 It is converted into a paving amount of glue-containing shavings per unit area, and the hot pressing time is set to 12 minutes, and a phenolic resin single-layer random structure bamboo shavings flat board with a standard quality of 2440mm long, 1220mm wide and 10mm thick is obtained. Instead of wooden boards, it can be used as outdoor packaging box boards and I-beam webs with good results.

Embodiment 3

[0051] Repeat Example 1, with the following differences: using raw hemp bamboo for more than 2 years, the bamboo stalks are cut into 150mm long bamboo tubes, and the bamboo tubes are sliced along the longitudinal diameter into 0.7±0.1mm thick bamboo shavings. Spray sizing with phenolic resin at a ratio of 8%. The target density is set to 0.836g / cm according to the relationship between the density of hemp bamboo, the average density of hemp bamboo board and the target performance. 3 And converted into paving amount of glue-containing shavings per unit area, pave the single-layer oriented structure slab according to the mean value of the axis angle β of the shavings of 30°±5° (as shown in Figure 8), set the hot pressing time to 13min, and press Obtained a phenolic resin single-layer oriented structure bamboo shavings flat board with a length of 2440mm, a width of 1220mm and a thickness of 10mm. Instead of wooden boards, it can be used as outdoor packaging box boards and I-beam web...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com