Composite paper reel and manufacturing method thereof

A manufacturing method and technology for paper rolls, applied in the field of paper rolls, can solve problems such as destruction of forest resources, unfavorable environmental protection, etc., and achieve the effects of saving costs, reducing damage, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

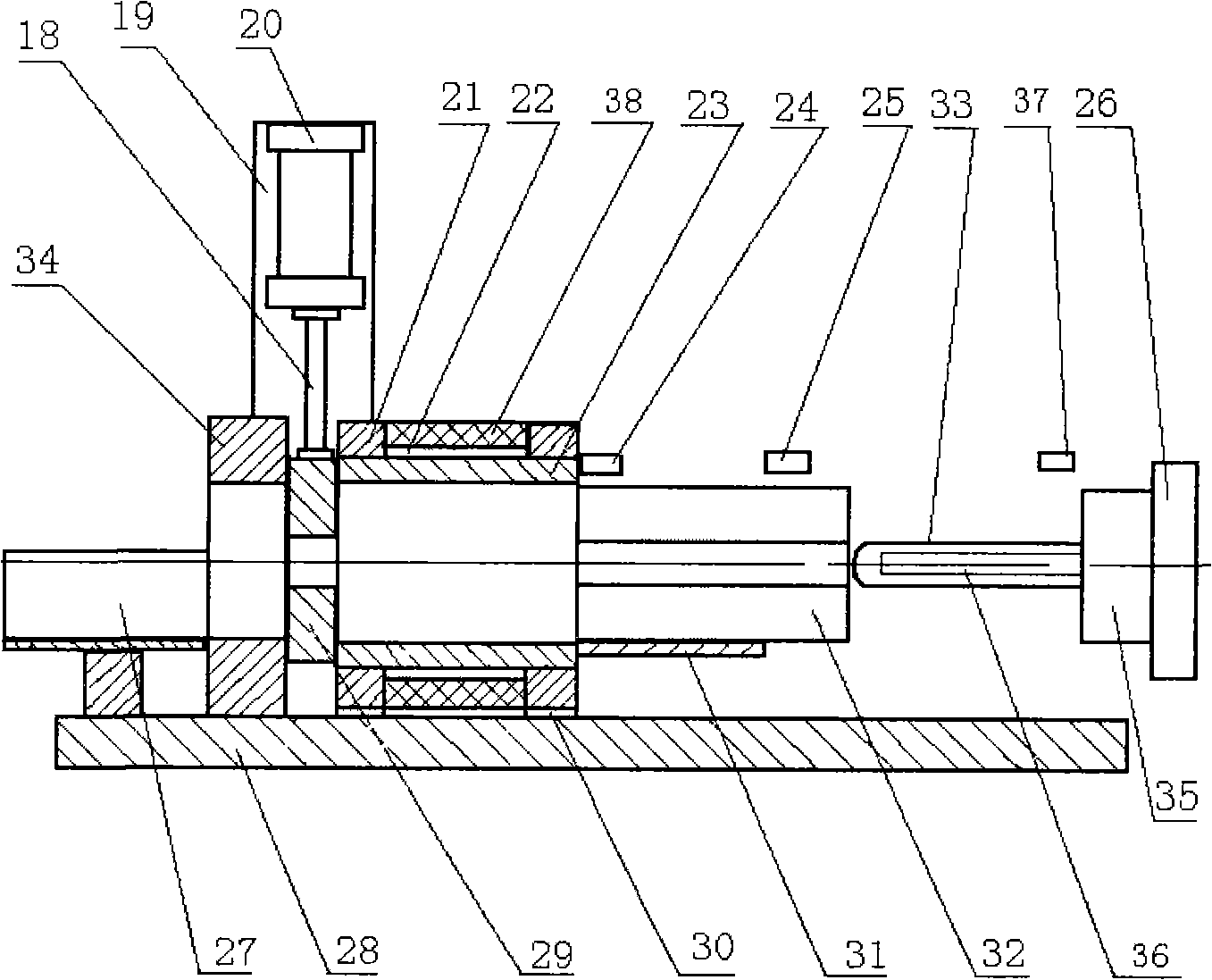

[0009] Below in conjunction with accompanying drawing, the present invention is further described:

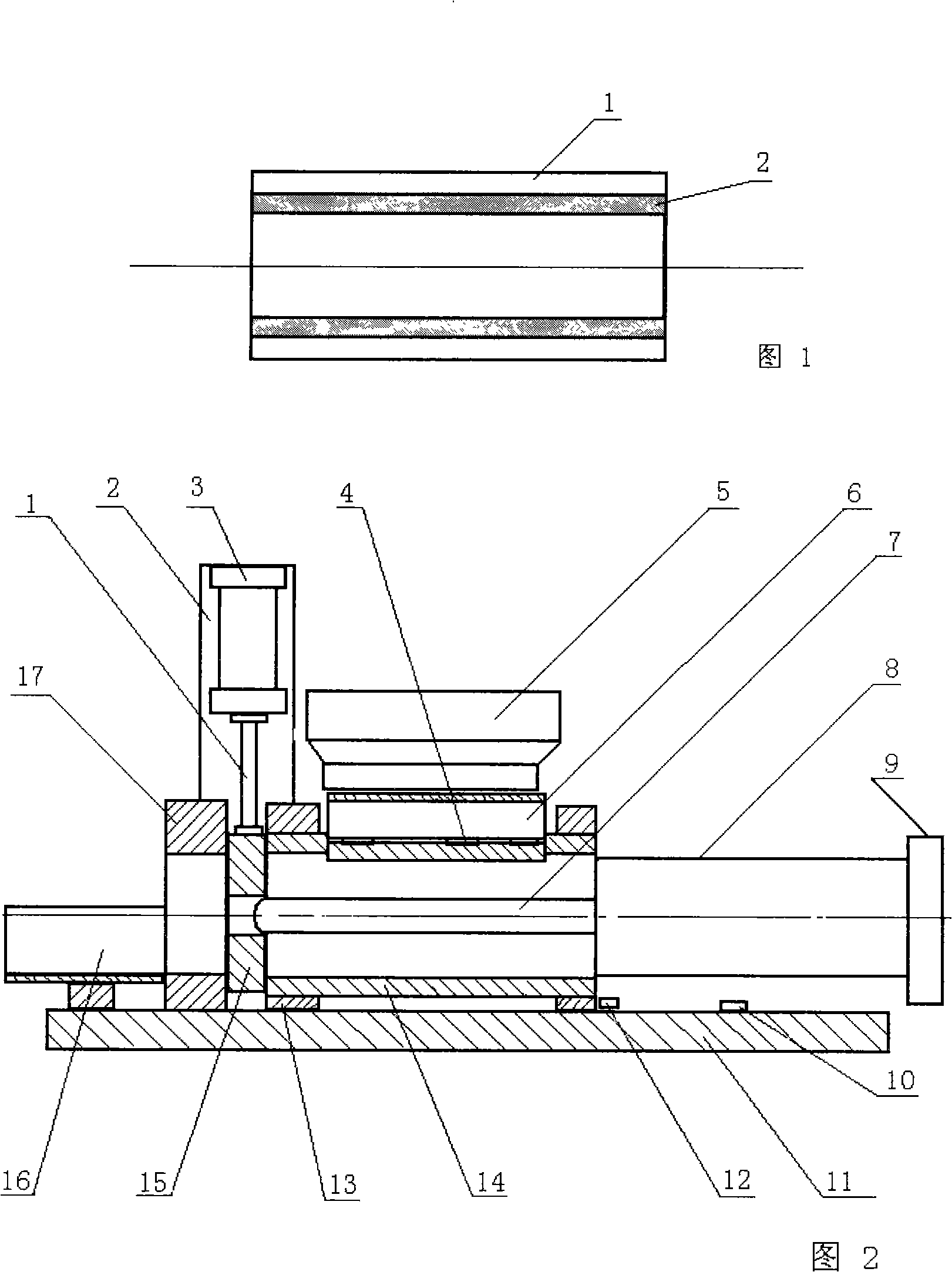

[0010] Figure 1, Figure 2, image 3 The composite paper roll and its manufacturing method are shown. The composite paper roll is composed of a molded fiber tube 2 and a roll paper roll 1. The outer layer of the composite paper roll is the roll paper roll 1, and the inner layer is a molded fiber tube 2. The fiber tube 2 is inside the roll paper tube 1, and the roll paper tube 1 is set on the outside of the molded fiber tube 2. The molded fiber tube 2 is composed of mixed resin fibers molded by heating and pressing; the mixed resin fibers molded by heating and pressing The fiber is composed of mixed resin bagasse fiber, or the mixed resin fiber formed by heating and pressing is composed of mixed resin shavings; the mixed resin fiber is not only composed of mixed resin bagasse fiber and mixed resin wood shavings, but also includes mixed resin cornstalk fiber, mixed resin bamboo fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com