Cloth soaking, printing and dyeing device and using method thereof

A cloth and dye box technology, applied in the field of printing and dyeing, can solve the problems of uneven printing and dyeing of cloth, low printing and dyeing efficiency, and large-scale existence, so as to avoid uneven printing and dyeing, ensure printing and dyeing effect, and improve printing and dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

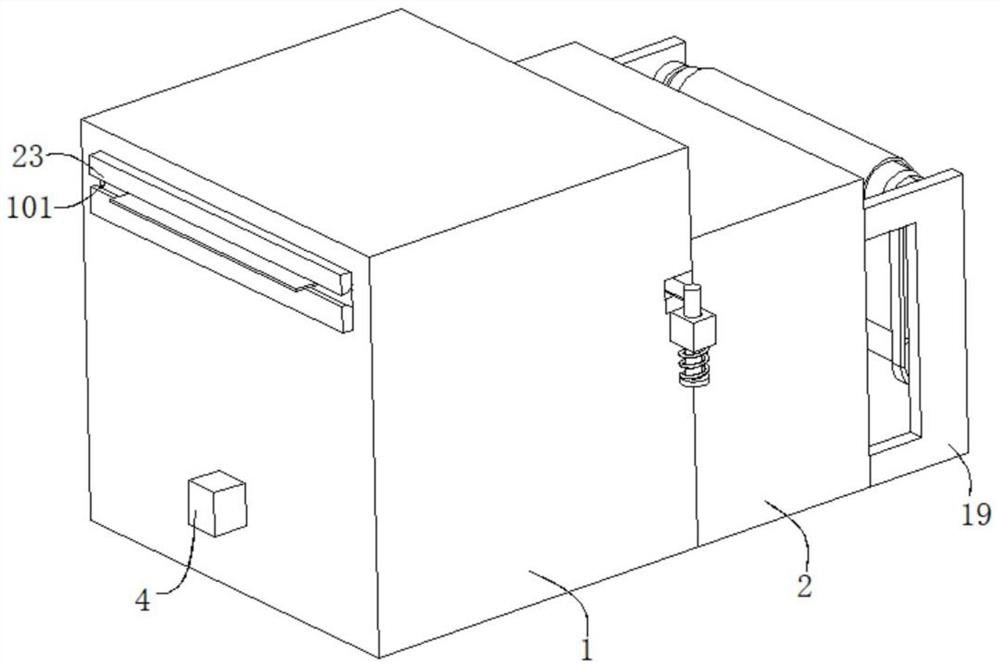

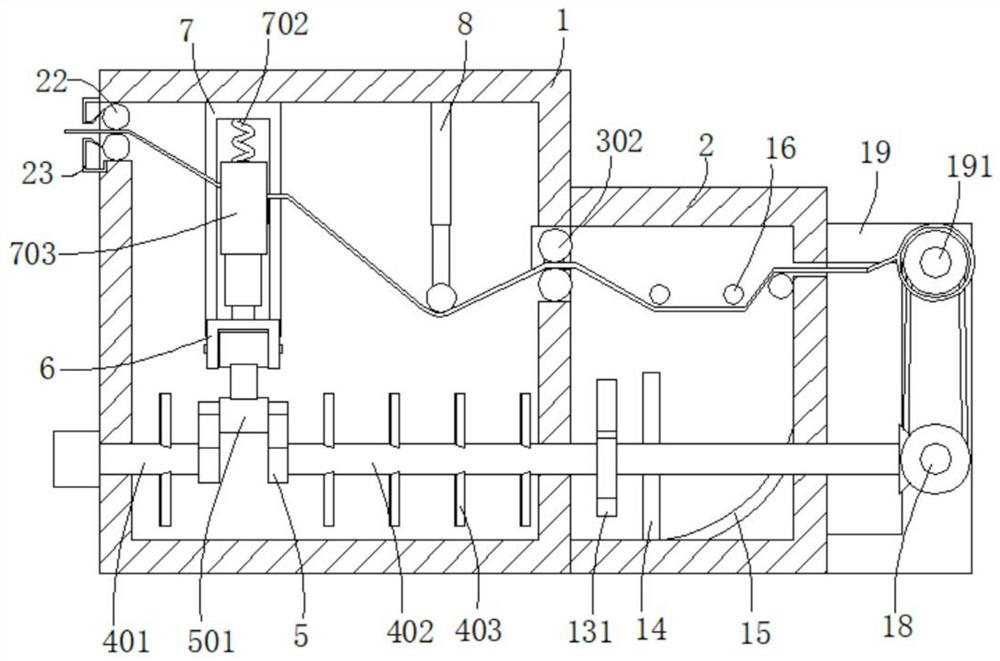

[0037] refer to Figure 1-5 , a cloth soaking printing and dyeing device, including a dye box 1 and a drying box 2, a through hole 3 is connected between the dye box 1 and the drying box 2, and the dye box 1 and the drying box 2 are connected to each other, and the outer wall of the dye box 1 A feed port 101 is excavated, a discharge port 201 is excavated on the outer wall of the drying box 2, a motor 4 is connected to the outer wall of the dye box 1, and a first rotating shaft 401 is connected to the output end of the motor 4, and the first rotating shaft 401 is rotatably connected to the dye box 1 The inner wall of the dye box 1 is also rotatably connected with a second rotating shaft 402 through a bearing, and the outer wall of the first rotating shaft 401 and the second rotating shaft 402 are connected with a stirring blade 403, and the first rotating shaft 401 and the second rotating shaft 402 are far away from the inner wall of the dye box 1. One end is connected with a ...

Embodiment 2

[0040] refer to figure 2 , image 3 , Figure 4 , Image 6 with Figure 7 , a cloth soaking printing and dyeing device, which is basically the same as that of Example 1, furthermore, the inner wall of the feed port 101 is connected with a dust-sticking roller group 22, and the upper and lower sides of the feed port 101 are also connected with a scraper box 23, and the scraper The box 23 is movable against the outer wall of the sticky roller group 22; by setting the sticky roller set 22 at the feed port 101, the sticky roller set 22 can clean up the dust and fluff adhering to both sides of the cloth, so as to avoid affecting the coloring and dyeing of the cloth effect, and by setting the scraper box 23 at the feed inlet 101, the scraper box 23 is offset against the dust-sticking roller group 22, and the dust and lint on the outside of the dust-sticking roller group 22 are scraped off, and the outer wall of the dust-sticking roller group 22 is prevented from being stained. ...

Embodiment 3

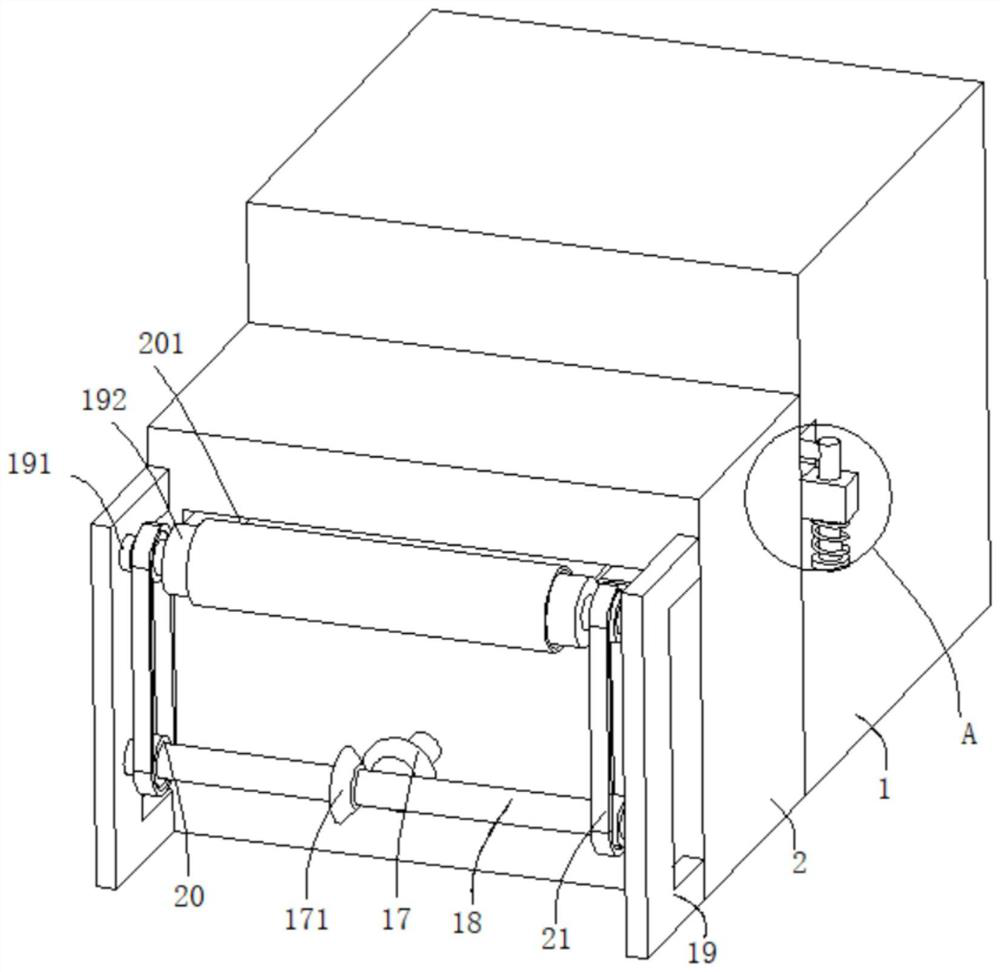

[0044] refer to Figure 1-7 , a cloth soaking printing and dyeing device, which is basically the same as Embodiment 1, furthermore, the end of the second rotating shaft 402 away from the dye box 1 passes through the drying box 2 and is connected with the first bevel gear 17, the first bevel gear 17 The outer wall is meshed with a second bevel gear 171, the inner wall of the second bevel gear 171 is connected with a first rotating shaft 18, and both ends of the first rotating shaft 18 are connected with a mounting frame 19, and the two mounting frames 19 are fixedly connected to the drying box. 2, the second rotating shaft 191 is also connected between the two placement frames 19, and the outer wall of the second rotating shaft 191 is sleeved with a cloth rolling roller 192, and the outer walls of the first rotating shaft 18 and the second rotating shaft 191 are connected with synchronous Wheel 20, a synchronous belt 21 is connected between the two synchronous wheels 20; by mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com