Method for calibrating sensitivity of multiple sensors

A calibration method, multi-sensor technology, applied in the testing/calibration of instruments, speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, etc. and other problems to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

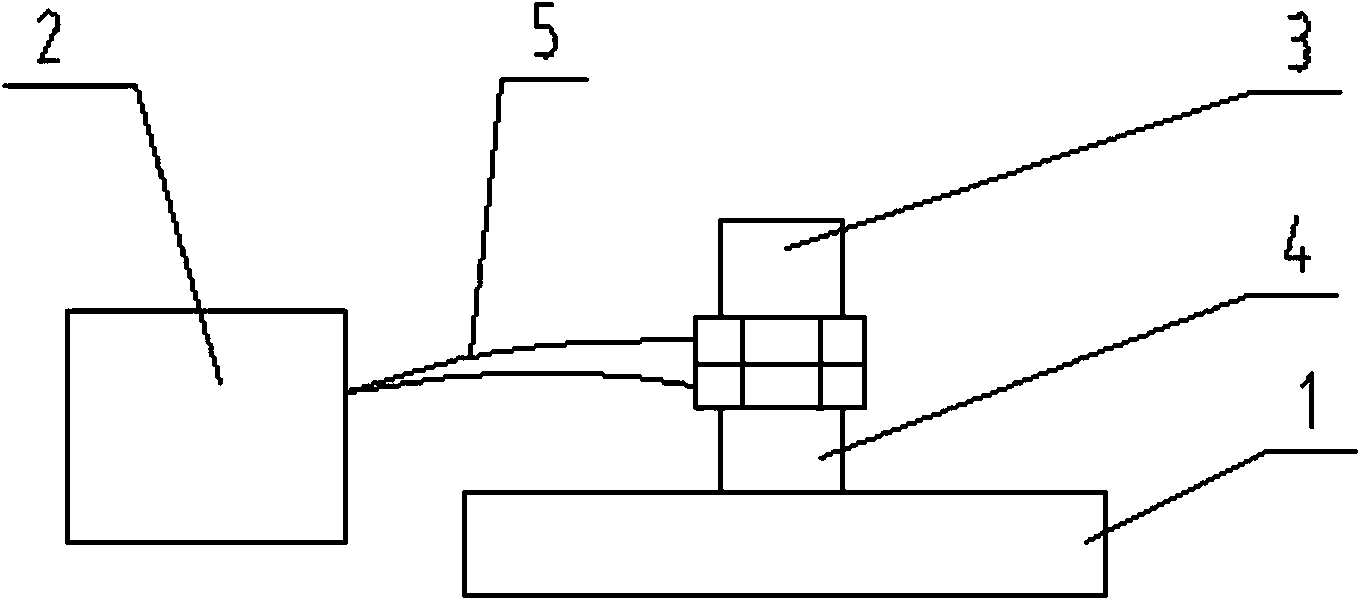

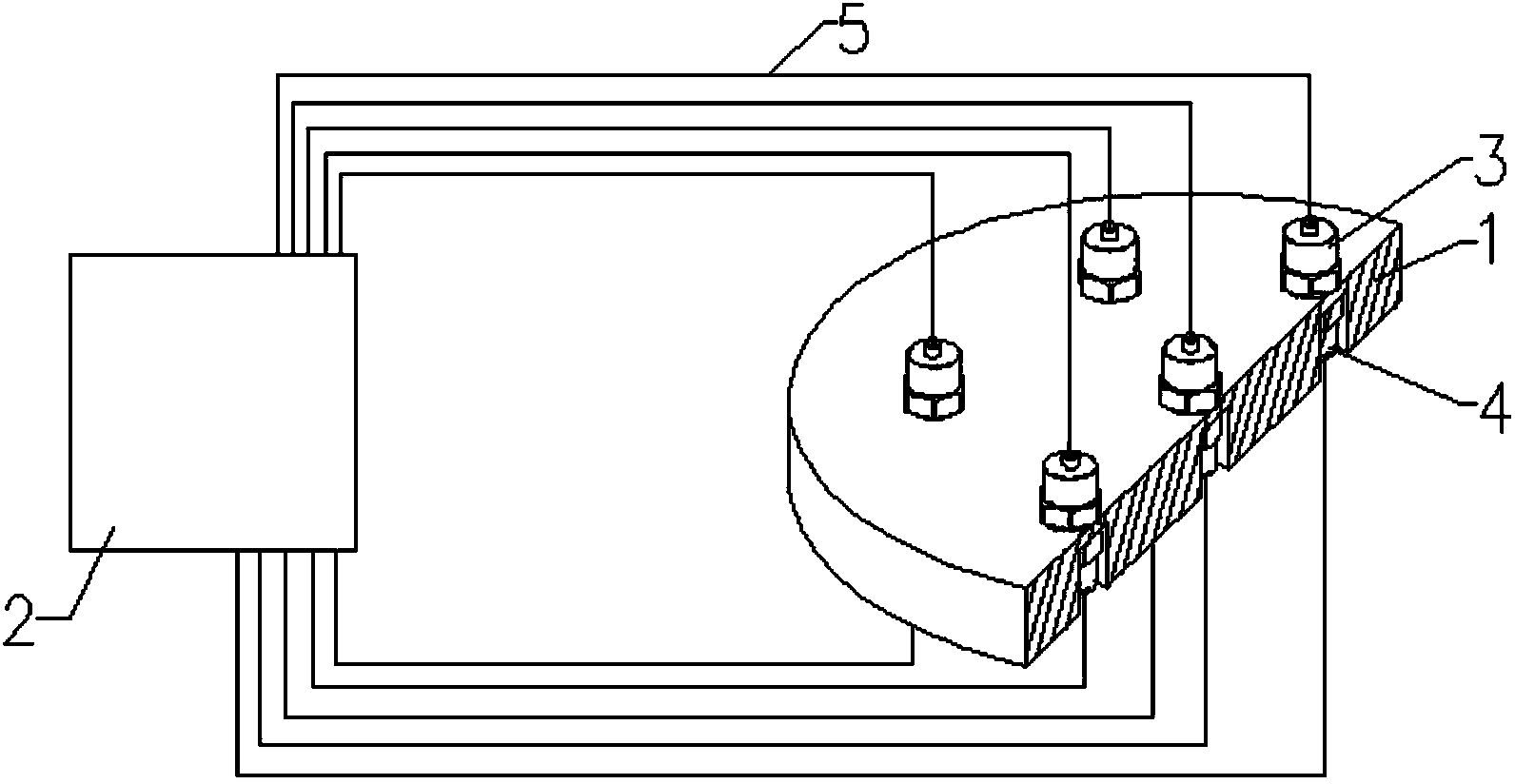

[0018] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

[0019] see figure 2 As shown, a calibration method for multi-sensor sensitivity includes the following steps:

[0020] (1) An acceleration sensor 3 to be calibrated and a standard acceleration sensor 4 are respectively fixed on the top of the worktable 1 and below the worktable 1 of the vibrating table in such a manner that the back faces are facing each other;

[0021] (2) According to the method of step (1), fix the multiple groups of acceleration sensors 3 to be calibrated and the standard acceleration sensors 4 on the worktable 1 in one-to-one correspondence;

[0022] (3) Electrically connect multiple groups of acceleration sensors 3 to be calibrated and standard acceleration sensors 4 to the detection device 2 .

[0023] Wherein, a mounting hole for installing the standard acceleration sensor 4 is provided un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com