Cross-section making method

A metallographic slicing and slicing technology, which is applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of inability to apply the first piece control of the process, expensive crystal base materials, and high slicing costs, so as to avoid batch defects and Potential risks, production cost reduction, and the effect of production cost reduction

Inactive Publication Date: 2017-03-29

江苏弘信华印电路科技有限公司

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The current section production usually uses liquid resin sealing method; the current acrylic resin and curing agent are prepared according to the ratio of 5:1; the curing process takes 40-60 minutes; the whole section takes at least 2 hours from sampling to microscope analysis, and the analysis time is relatively short. Long, can only be applied to failure analysis, but not to process first article control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement of the technical features of the technical solution of the present invention and conventional reasoning shall fall into the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

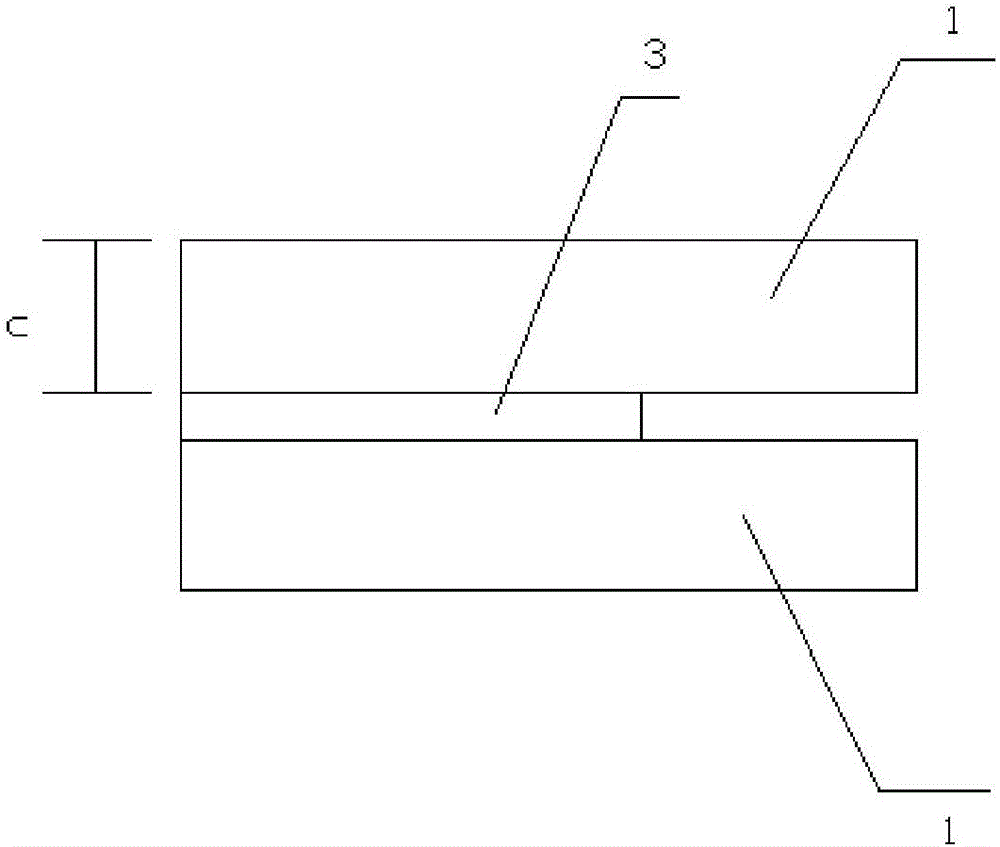

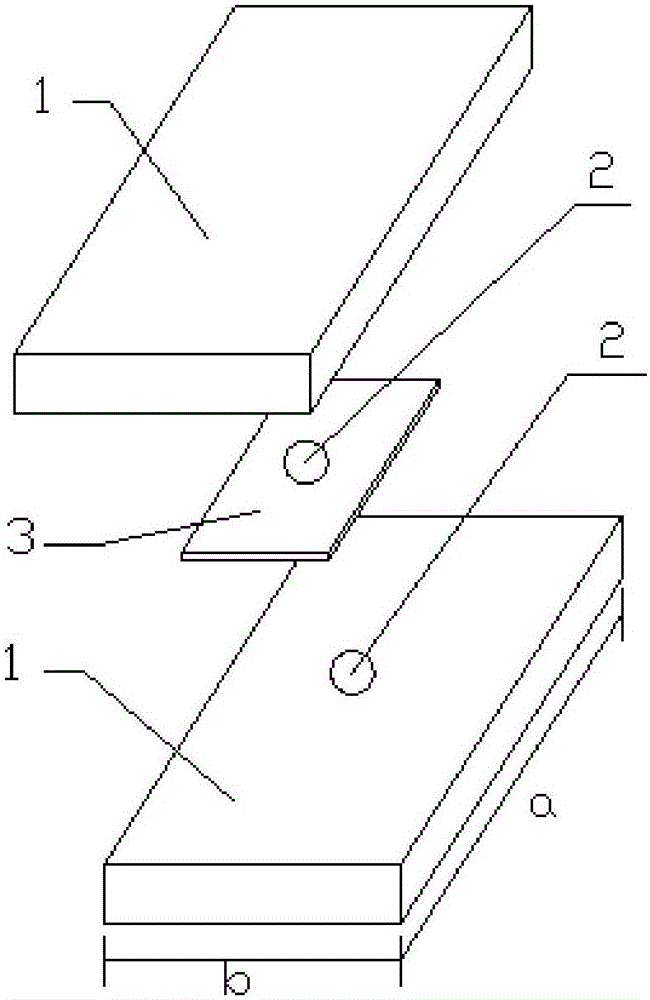

The invention relates to a cross-section making method. The method particularly comprises the following steps that 1, two organic glass plates of a cuboid structure are prepared, and 502 glue is prepared to serve as an adhesive; 2, a measured object is taken as a sample; 3, one piece of organic glass plate is placed on an operating platform, and the adhesive is dropwise added to the center of the organic glass for the first time; 4, the measured object is placed on the organic glass on which the adhesive is dropwise added; 5, the adhesive is dropwise added to the measured object for the second time; 6, the other piece of organic glass is placed on the measured object in a press-fit mode, and the two pieces of organic glass are adhered into a whole to form an initial blank of a section; 7, the initial blank of the section is ground till the observation position is ground. According to the cross-section making method, the time of the whole process is greatly shortened, the making cost is greatly reduced, bubbling cannot be generated, and the section success rate is high.

Description

Technical field [0001] The invention relates to a method for making metallographic slices, and belongs to the technical field of quality control and failure analysis in the manufacturing process of a soft-hard board. Background technique [0002] Metallographic sectioning, also known as sectioning, cross-section, x-section, is a sample preparation method in which the sample is wrapped and sealed with resin liquid resin, and then ground and polished. The inspection process includes sampling, solid sealing, grinding, polishing, Finally, provide topography photos, crack layer size judgment, or size and other data. It is the most commonly used sample preparation method to observe the cross-sectional structure of the sample. [0003] The current section production usually uses liquid resin sealing glue; the current acrylic resin and curing agent are prepared in a ratio of 5:1; the curing process takes 40-60 minutes; the entire section from sampling to microscopic analysis requires at l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N1/28G01N1/36

CPCG01N1/2813G01N1/286G01N1/36G01N2001/2833G01N2001/2866

Inventor 郑冬华

Owner 江苏弘信华印电路科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com