Stiffness tester of paper and paperboards, and method thereof for automatically controlling chuck restoration

A measuring instrument and cardboard technology, which is applied in the direction of control, instrument, and measuring device using feedback, can solve the problems of deviation and error in test results, and achieve the effect of accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

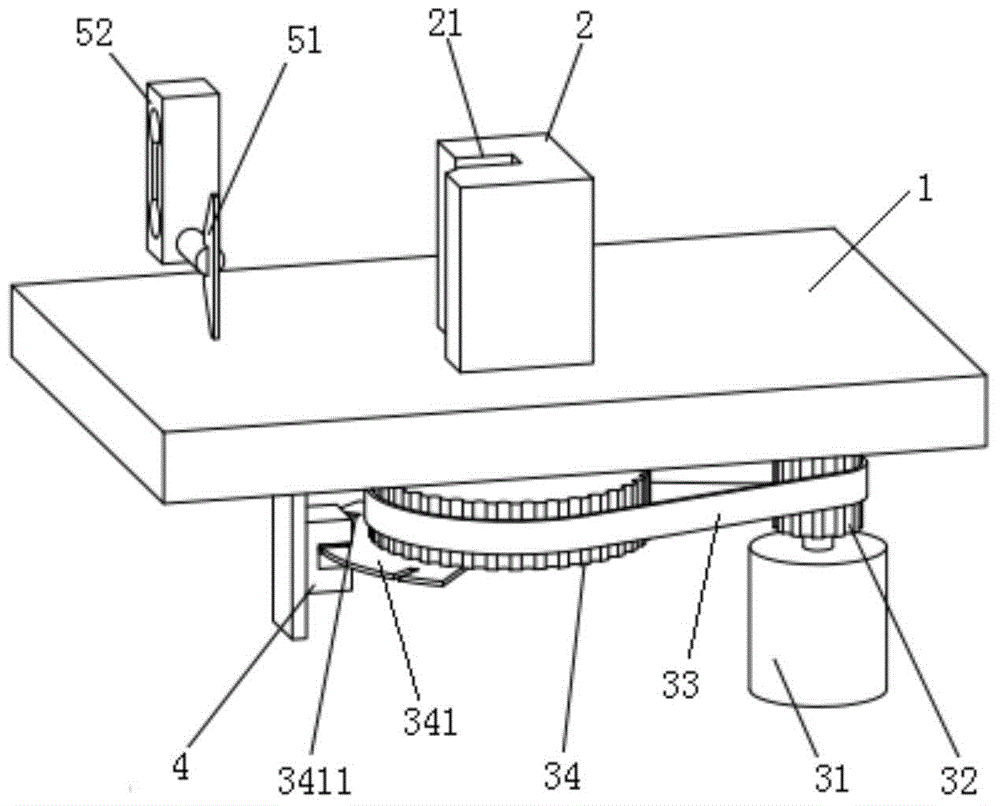

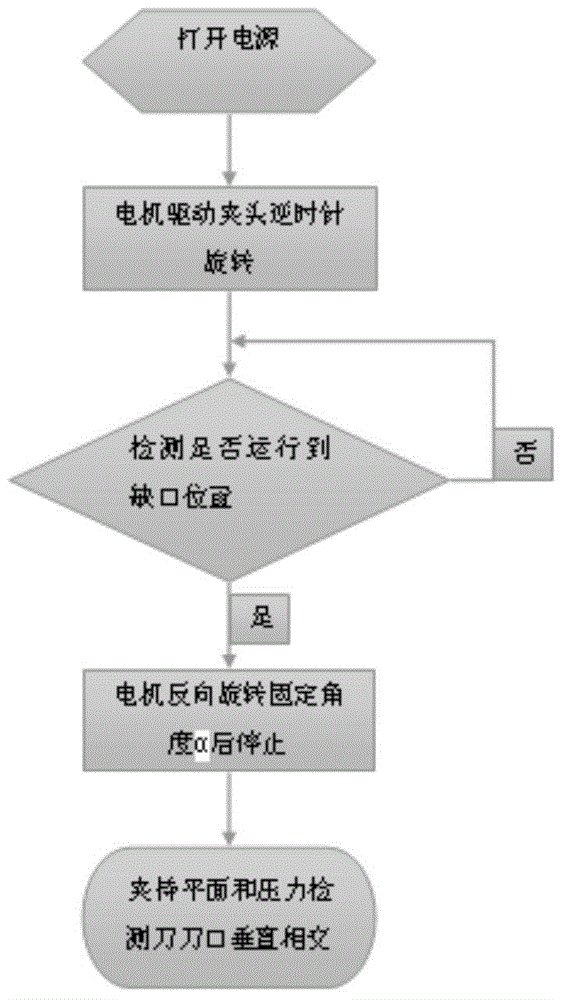

[0023] see figure 1 , the stiffness tester for paper and cardboard of the present invention comprises a table top 1, chuck 2, pressure detection knife 51, drive mechanism and automatic reset device, chuck 2 is arranged on the top surface of table top 1, and pressure detection knife 51 is fixedly arranged On one side of the collet 2, the rotating shaft of the collet 2 passes through the table top and is connected with the driving mechanism arranged under the table, the driving mechanism includes a rotating wheel 34 and a driver 31, and the rotating shaft of the collet 2 is fixedly connected with the rotating wheel 34, The driver 31 can drive the rotating wheel 34 to rotate and then drive the chuck 2 to rotate; the automatic reset device includes a photoelectric sensor 4, a controller and an arc detection plate 341 arranged on the edge of the rotating wheel. The arc detection plate 341 is provided with a photoelectric sensor that can detect According to the detection structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com