Paint spraying device for inner wall of ventilating duct

A technology for ventilation pipes and air pipes, which is applied to spray devices, liquid spray devices, paint spray booths, etc., can solve the problems of reduced production efficiency, poor paint uniformity and adhesion, and poor protection of the inner wall of ventilation pipes, and achieves strong heat fluidity. , easy to spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

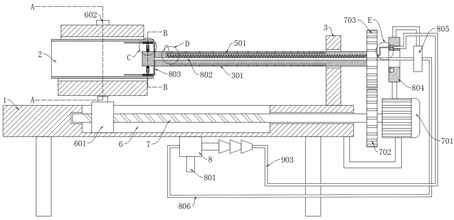

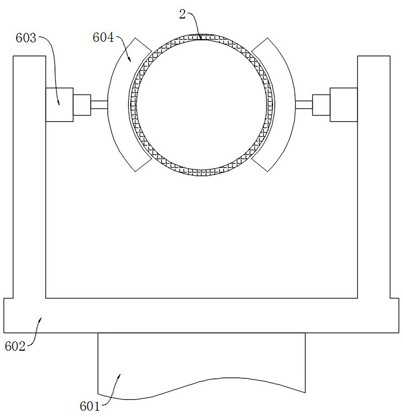

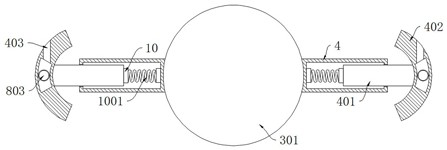

[0025] refer to Figure 1-6 , a painting device for the inner wall of a ventilation duct, comprising a workbench 1 and a ventilation duct 2, the upper end of the workbench 1 is fixedly connected with a vertical rod 3, the side wall of the vertical rod 3 is rotatably connected with a rotating rod 301, and the side wall of the rotating rod 301 is fixedly connected with a spray head 302, a cleaning mechanism is installed on the rotating rod 301, the cleaning mechanism includes two hollow rods 4 symmetrically fixedly connected to the side wall of the rotating rod 301, the inner wall of the hollow rod 4 is slidably connected to a sliding rod 401, and the upper end of the sliding rod 401 is fixedly connected to an arc Scraper 402, arc-shaped scraper 402 is provided with dust suction groove 403, and the side wall of dust suction groove 403 is provided with dust suction hole 404. There is a drying mechanism, the drying mechanism includes an annular groove 5 provided in the rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com