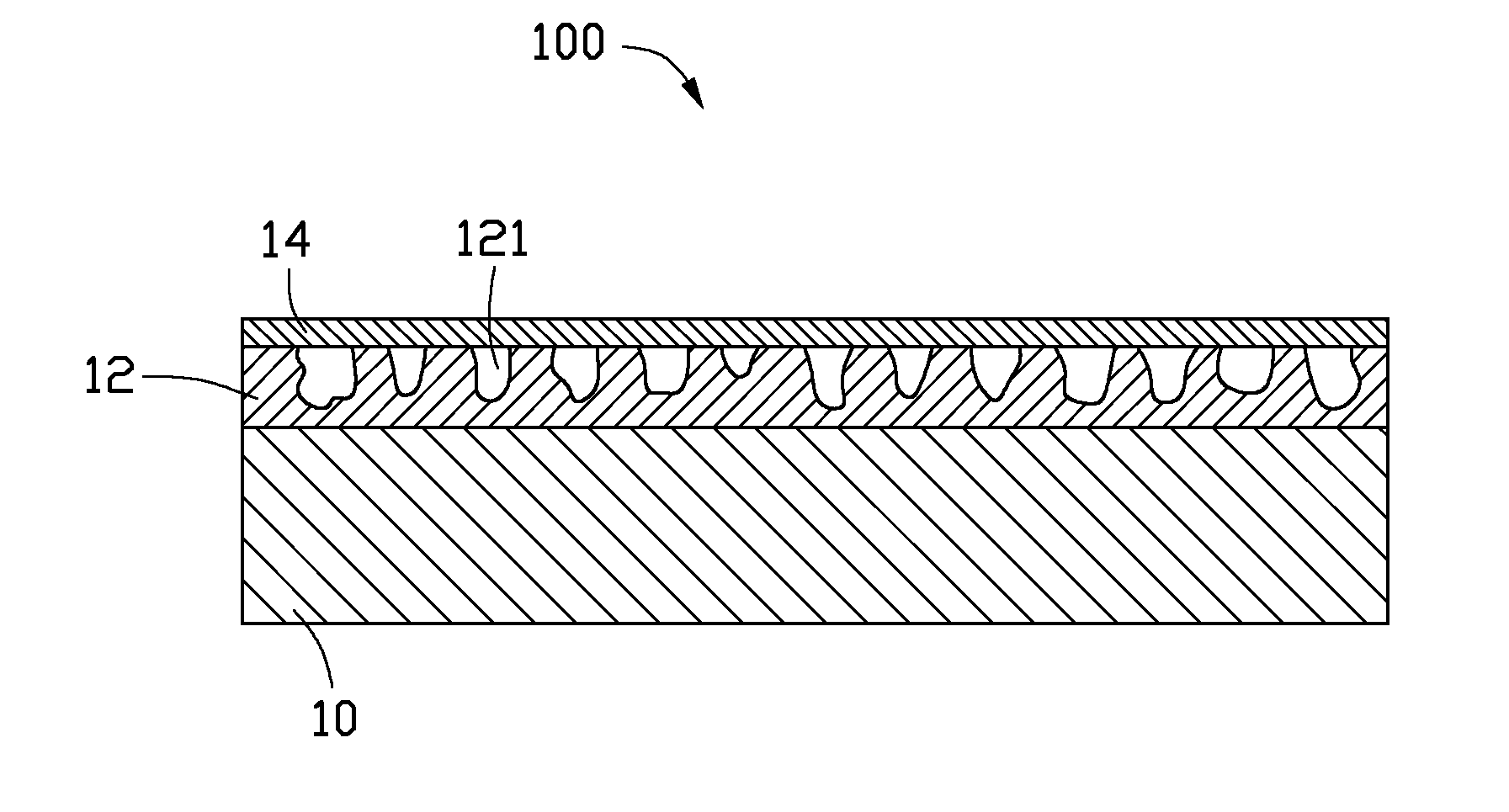

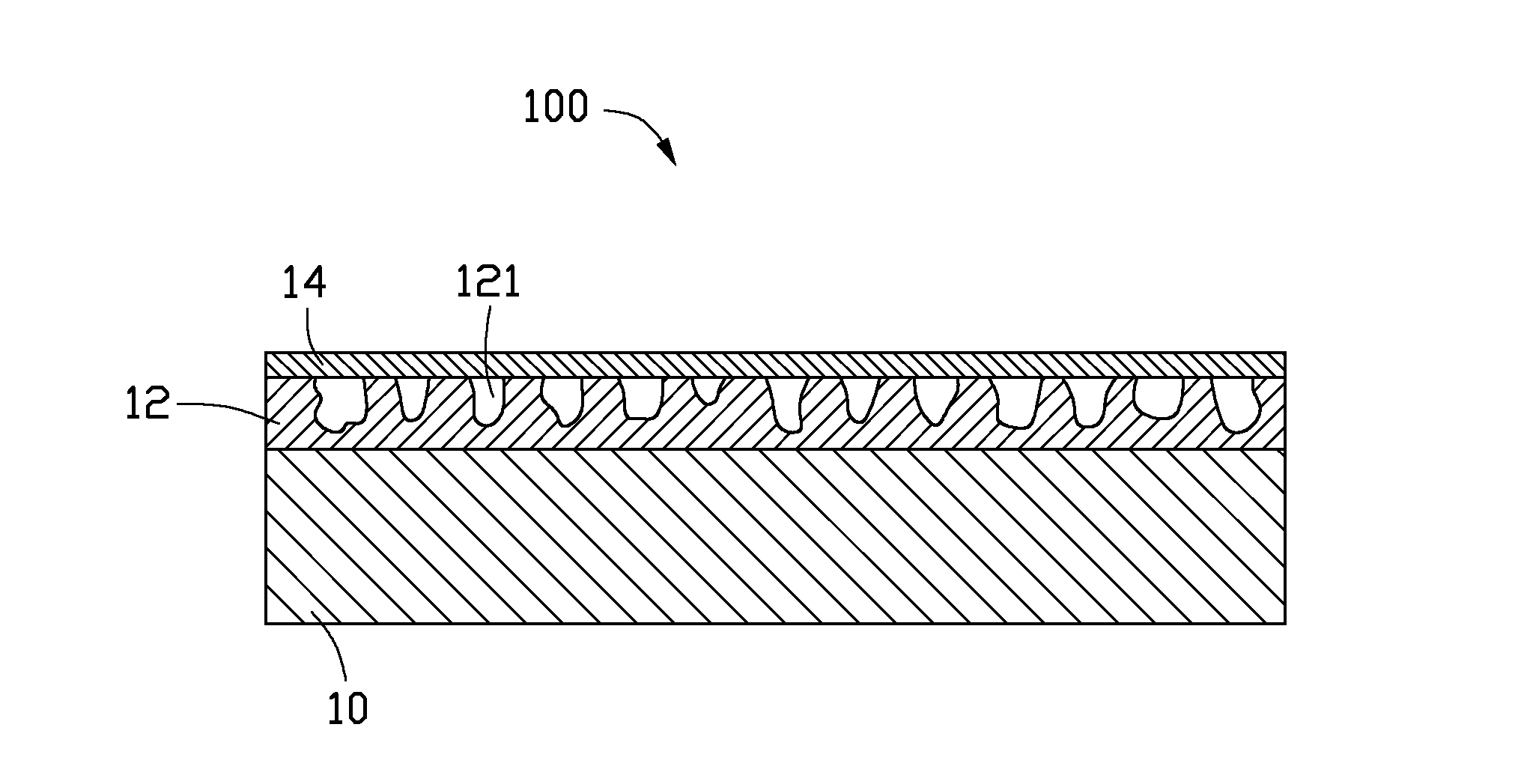

Surface treatment process for aluminum alloy and aluminum alloy article thereof

a surface treatment process and aluminum alloy technology, applied in the direction of superimposed coating process, cell components, coatings, etc., can solve the problem of uneven color of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023]In air drying the substrate 10: the substrate 10 was dried by a dryer (not shown) for 2 min.

[0024]In solution treating the substrate 10: the furnace had an inner temperature of about 525° C., the substrate 10 was positioned in the furnace to be solution treated for about 8 hours.

[0025]In quenching the substrate 10: the substrate 10 was dipped in water having a temperature of about 20° C. for 5 min.

[0026]In acid treating the substrate 10: the substrate 10 was dipped in the acid solution for 5 min The acid solution contained nitric acid and hydrofluoric acid in a volume ratio of 8:1. After the acid treatment, the total content of the silicon element contained in the substrate 10 decreased about 1.3%.

[0027]In polishing the substrate 10: the substrate 10 was dipped in a first polishing solution having a temperature of about 70° C. for 20 seconds. The first polishing solution contained sulfuric acid and phosphoric acid in a volume ratio of 1:3. Then the substrate 10 was dipped in a...

example 2

[0031]In air drying the substrate 10: the substrate 10 was dried by a dryer for 2 min.

[0032]In solution treating the substrate 10: the furnace had an inner temperature of about 510° C., the substrate 10 was positioned in the furnace to be solution treated for about 9 hours.

[0033]In quenching the substrate 10: the substrate 10 was dipped in water having a temperature of about 15° C. for 5 min.

[0034]In acid treating the substrate 10: the substrate 10 was dipped in the acid solution for 5 min The acid solution contained nitric acid and hydrofluoric acid in a volume ratio of 10:1.5. After the acid treatment, the total content of the silicon element contained in the substrate 10 decreased about 1.5%.

[0035]In polishing the substrate 10: the substrate 10 was dipped in a first polishing solution having a temperature of about 75° C. for 20 seconds. The first polishing solution contained sulfuric acid and phosphoric acid in a volume ratio of about 1:5. Then the substrate 10 was dipped in a se...

example 3

[0039]In air drying the substrate 10: the substrate 10 was dried by a dryer for 3 min.

[0040]In solution treating the substrate 10: the furnace had an inner temperature of about 495° C., the substrate 10 was positioned in the furnace to be solution treated for about 10 hours.

[0041]In quenching the substrate 10: the substrate 10 was dipped in water having a temperature of about 20° C. for 5 min.

[0042]In acid treating the substrate 10: the substrate 10 was dipped in the acid solution for 10 min The acid solution contained nitric acid and hydrofluoric acid in a volume ratio of 9:1. After the acid treatment, the total content of the silicon element contained in the substrate 10 decreased about 1.65%.

[0043]In polishing the substrate 10: the substrate 10 was dipped in a first polishing solution having a temperature of about 80° C. for 30 seconds. The first polishing solution contained sulfuric acid and phosphoric acid in a volume ratio of about 1:4. Then the substrate 10 was dipped in a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com