Preparation method for Al-Cu-Li series aluminum-lithium alloy plate

A technology of al-cu-li and aluminum-lithium alloy, which is applied in the field of preparation of Al-Cu-Li series aluminum-lithium alloy sheet, can solve the problem that the size target and performance uniformity are difficult to achieve synergistically, so as to avoid the uneven structure of the sheet area The effect of uniformity problem, reduction of performance loss, and improvement of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

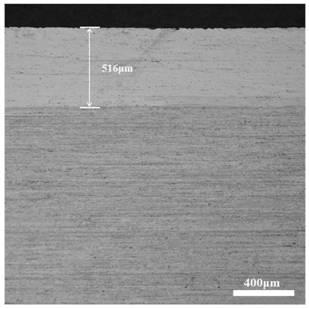

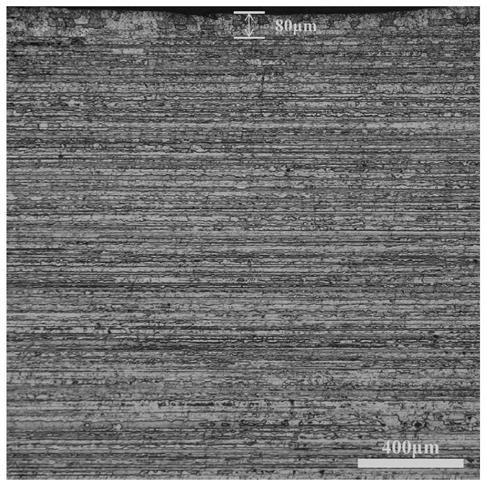

Embodiment 1

[0031] The aluminum-lithium alloy ingot is first heated to 120°C and held for 12 hours, then heated to 370°C and held for 10 hours, then heated to 420°C and held for 8 hours, and finally heated to 510°C and held for 18 hours, then the head and tail are sawed and milled. After the hot-rolled billet is preheated to 510°C, it is rolled into a plate with a thickness of 25mm. The surface temperature of the plate during the rolling process is not lower than 330°C. After solution and quenching treatment at 510°C / 3h, pre-stretch deformation with a deformation amount of 2%, and finally artificial aging treatment at 160°C / 24h, the final aluminum-lithium alloy plate is obtained.

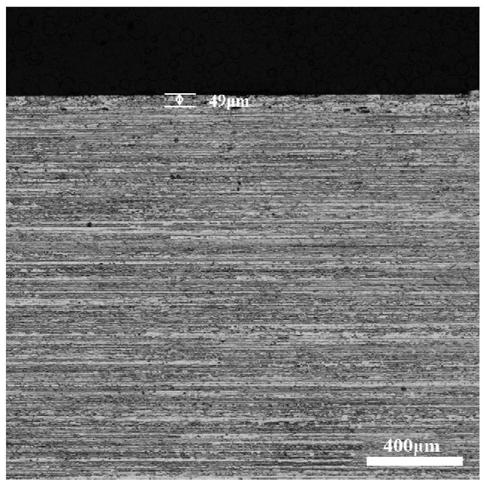

Embodiment 2

[0033] The aluminum-lithium alloy ingot is first heated to 120°C and held for 12 hours, then heated to 350°C and held for 10 hours, then heated to 450°C and held for 8 hours, finally heated to 510°C and held for 18 hours, and then sawed and milled. After the hot-rolled billet is preheated to 510°C, it is rolled into a plate with a thickness of 25mm. The surface temperature of the plate during the rolling process is not lower than 330°C. Perform solid solution at 510°C / 3h, immediately water quench to room temperature, perform pre-stretch deformation with 2% deformation, and finally obtain the final aluminum-lithium alloy plate after artificial aging treatment at 160°C / 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com