Multifunctional graphene/PET composite film, and preparation method thereof

A graphene and composite membrane technology, applied in the field of membrane materials, can solve the problems of being unsuitable for actual production, complex preparation process, and high cost, and achieve the effects of improved UV protection, improved compatibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

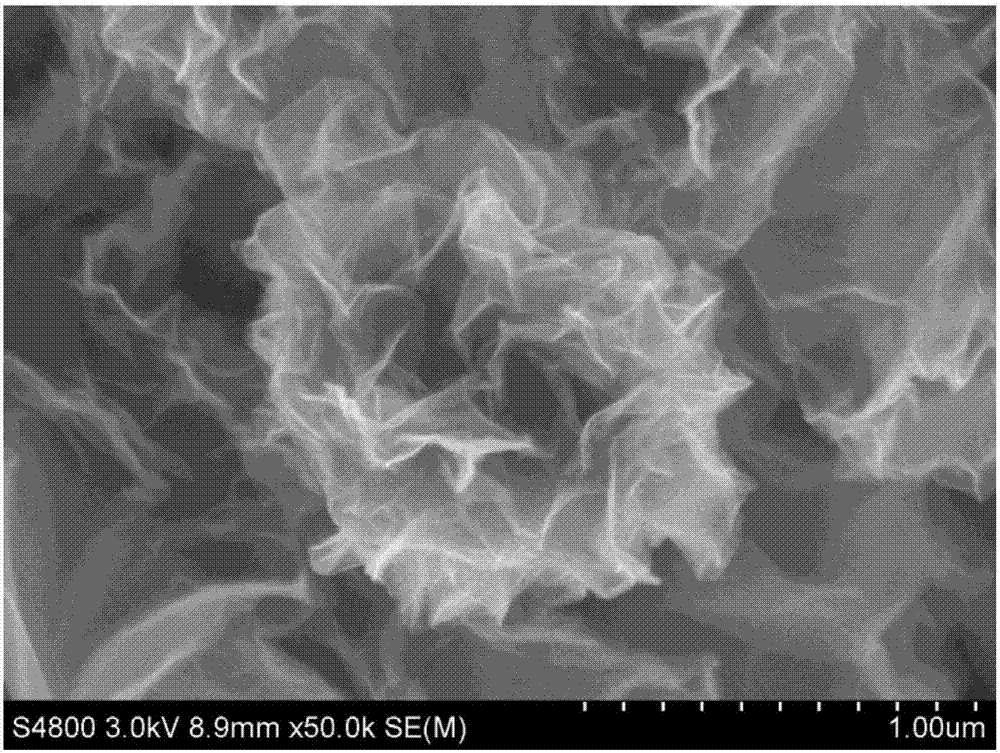

Image

Examples

Embodiment 1

[0025] (1) drying the single-layer graphene oxide dispersion by an atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130° C., the size of the graphene oxide sheet is 1 to 3 microns, and the carbon-to-oxygen ratio is 2.5;

[0026] (2) Fully mix and stir 100 parts by mass of terephthalic acid, 53 parts by mass of ethylene glycol, and 0.02 parts by mass of sodium acetate, and carry out esterification reaction at 250°C until anhydrous is produced;

[0027] (3) Add 0.117 parts by mass of pleated spherical graphene oxide obtained in step (1) and 0.018 parts by mass of ethylene glycol antimony to the esterified product obtained in step (2), keep stirring for 2 hours, and the stirring speed is 160 rpm , then heated up to 285°C and vacuumized, the reaction was carried out until the system no longer exothermic, and the graphene / PET nanocomposite material was obtained by water-cooling and pelletizing.

[0028] (4) 100 parts by mass of the gra...

Embodiment 2

[0031] (1) drying the single-layer graphene oxide dispersion by an atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C, the size of the graphene oxide sheet is 10-15 microns, and the carbon-oxygen ratio is 2.5;

[0032] (2) Fully mix and stir 100 parts by mass of terephthalic acid, 53 parts by mass of ethylene glycol, and 0.02 parts by mass of sodium acetate, and carry out esterification reaction at 250°C until anhydrous is generated;

[0033](3) Add 0.117 parts by mass of pleated spherical graphene oxide obtained in step (1) and 0.018 parts by mass of ethylene glycol antimony to the esterified product obtained in step (2), keep stirring for 2 hours, and the stirring speed is 160 rpm , then heated up to 285°C and vacuumized, the reaction was carried out until the system no longer exothermic, and the graphene / PET nanocomposite material was obtained by water-cooling and pelletizing.

[0034] (4) 100 parts by mass of the graphene / ...

Embodiment 3

[0037] (1) drying the single-layer graphene oxide dispersion by an atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C, the size of the graphene oxide sheet is 40-45 microns, and the carbon-oxygen ratio is 2.5;

[0038] (2) Fully mix and stir 100 parts by mass of terephthalic acid, 53 parts by mass of ethylene glycol, and 0.02 parts by mass of sodium acetate, and carry out esterification reaction at 250°C until anhydrous is generated;

[0039] (3) Add 0.117 parts by weight of pleated spherical graphene oxide obtained in step (1) and 0.018 parts by weight of ethylene glycol antimony to the esterified product obtained in step (2), keep stirring for 2 hours, and the stirring speed is 160 rpm , then heated up to 285°C and vacuumized, the reaction was carried out until the system no longer exothermic, and the graphene / PET nanocomposite material was obtained by water-cooling and pelletizing.

[0040] (4) 100 parts by mass of the grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com