RF Plasma Source With Conductive Top Section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A plasma source of the present invention provides a uniform ion flux and also dissipates the effects of secondary electrons. Some aspects of the plasma source of the present invention are described in connection with plasma doping for the purpose of illustrating the invention. However, it is understood that the plasma source of the present invention has many applications and is not limited to plasma immersion sources for plasma doping.

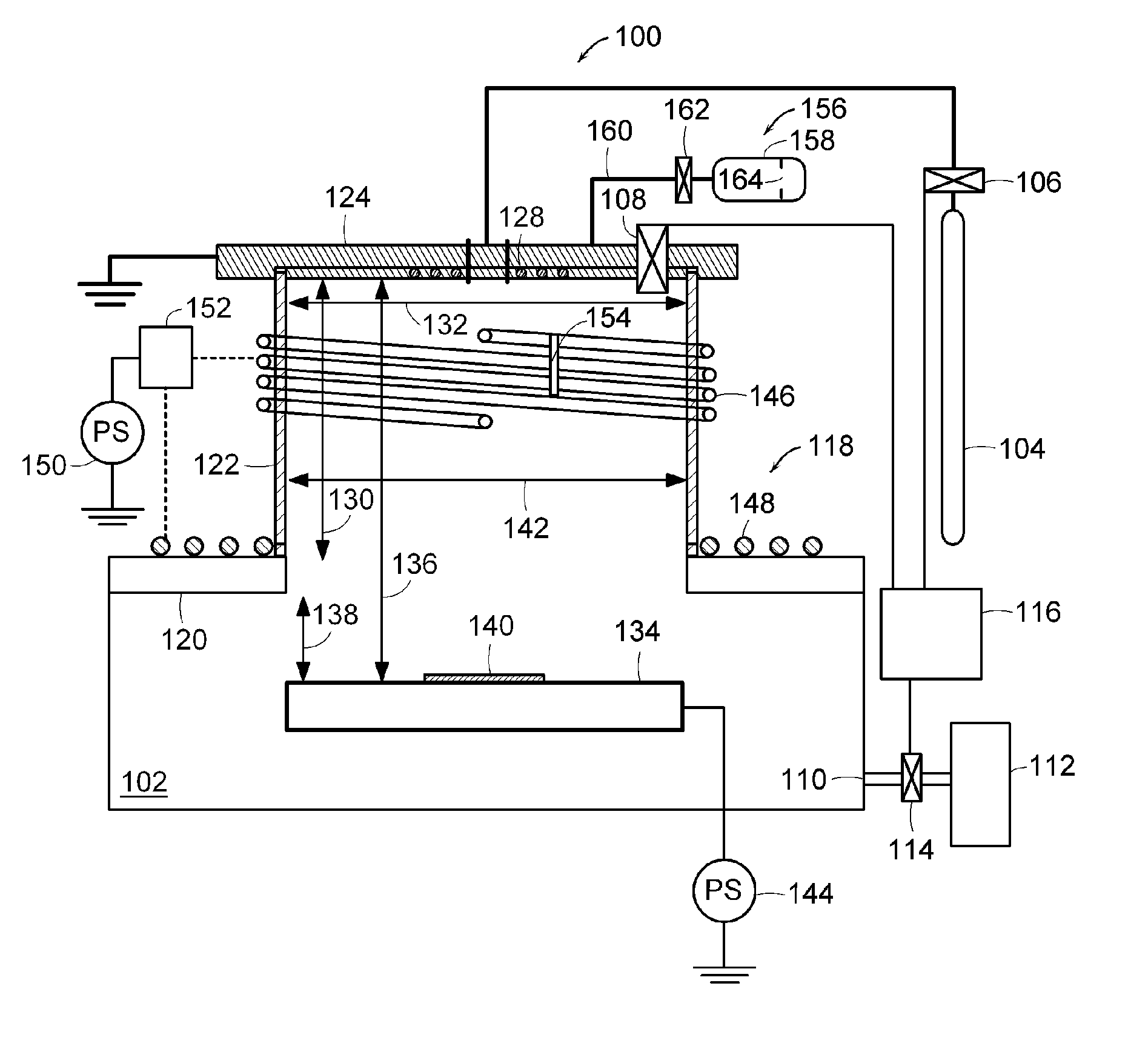

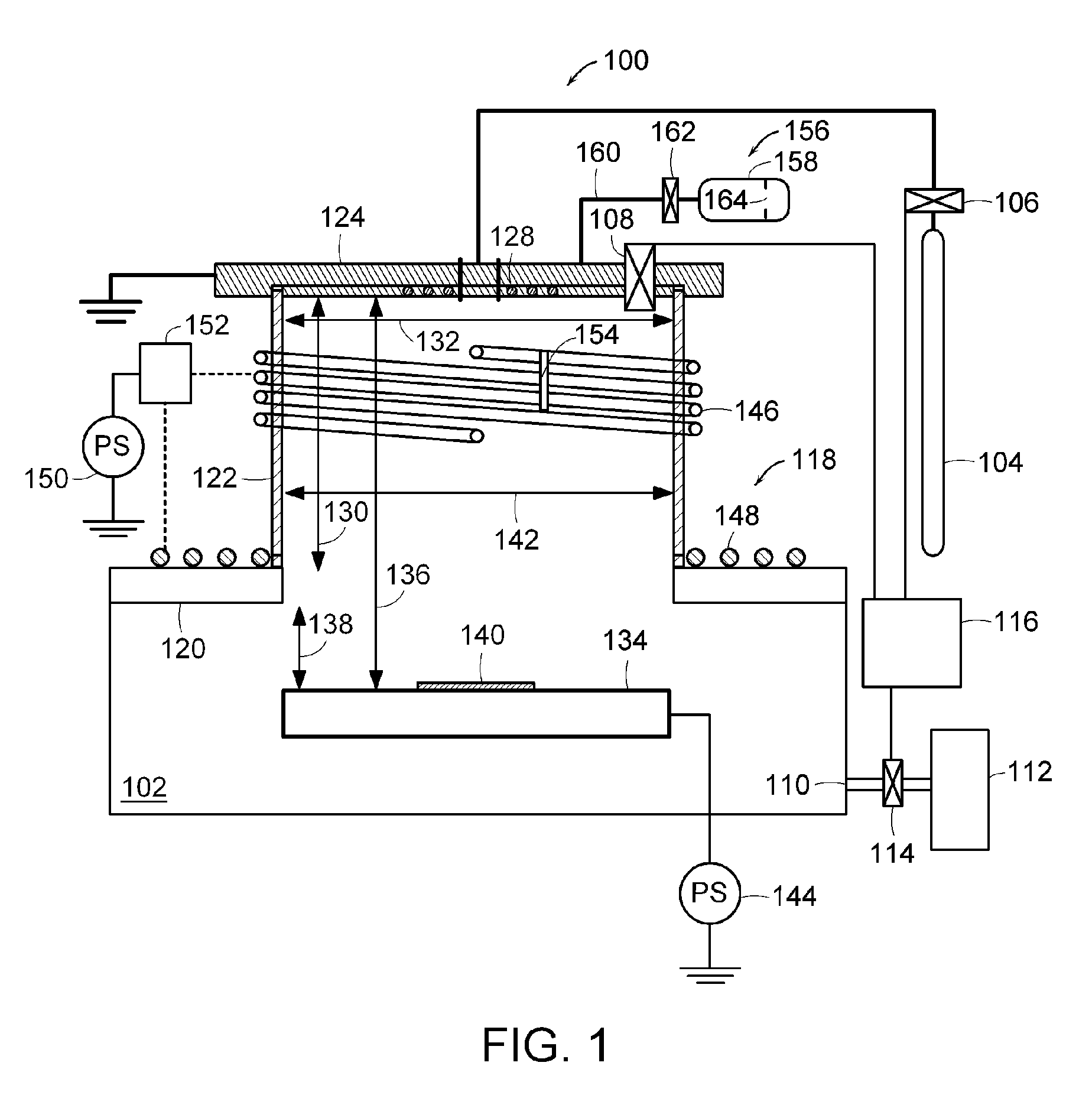

[0015]FIG. 1 illustrates a RF plasma source 100 having vertical and horizontal RF coils and a conductive top section according to the present invention. The plasma source 100 includes a chamber 102 that contains a process gas. A gas source 104 that is coupled to the chamber 102 through a proportional valve 106 supplies the process gas to the chamber 102. A pressure gauge 108 measures the pressure inside the chamber 102. An exhaust port 110 in the chamber 102 is coupled to a vacuum pump 112 that evacuates the chamber 102. An exhaust valve 114 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com