Plate polishing paint spraying device for machining

A technology of mechanical processing and plate, which is applied in the field of plate grinding and spraying equipment for mechanical processing, can solve the problems of low degree of automation, unfavorable work efficiency, troublesome use, etc., and achieve the effect of high degree of automation, saving working time and short use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

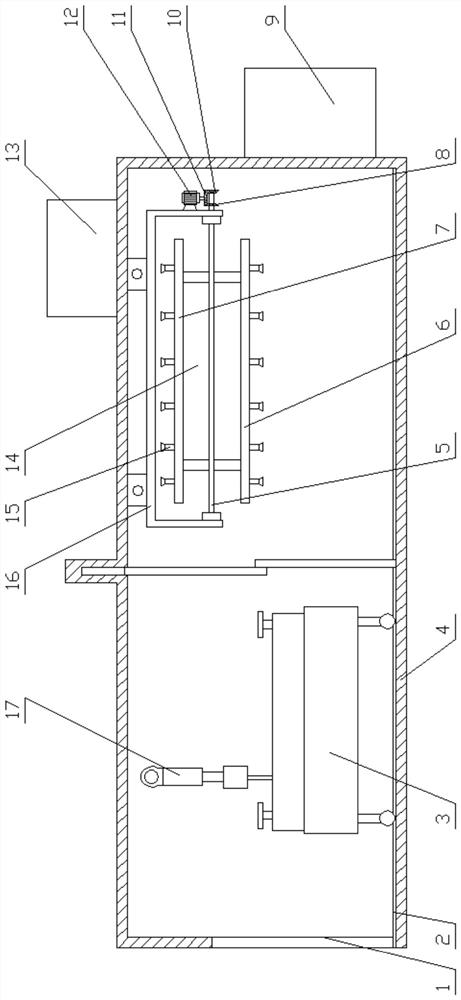

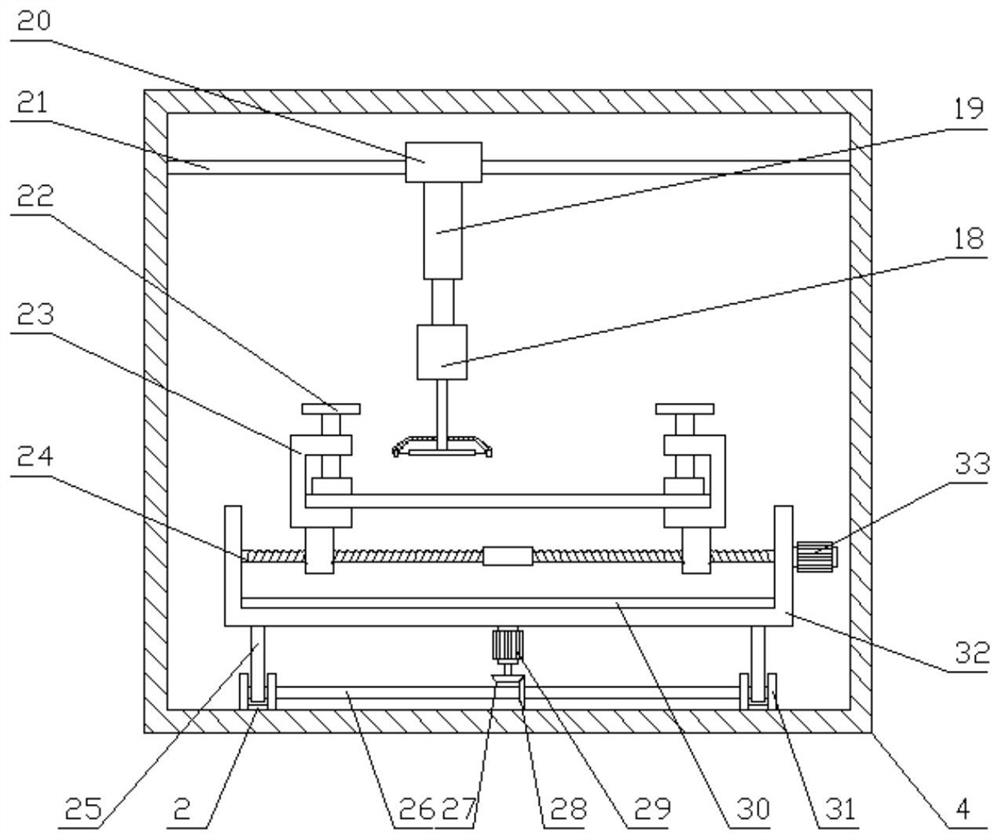

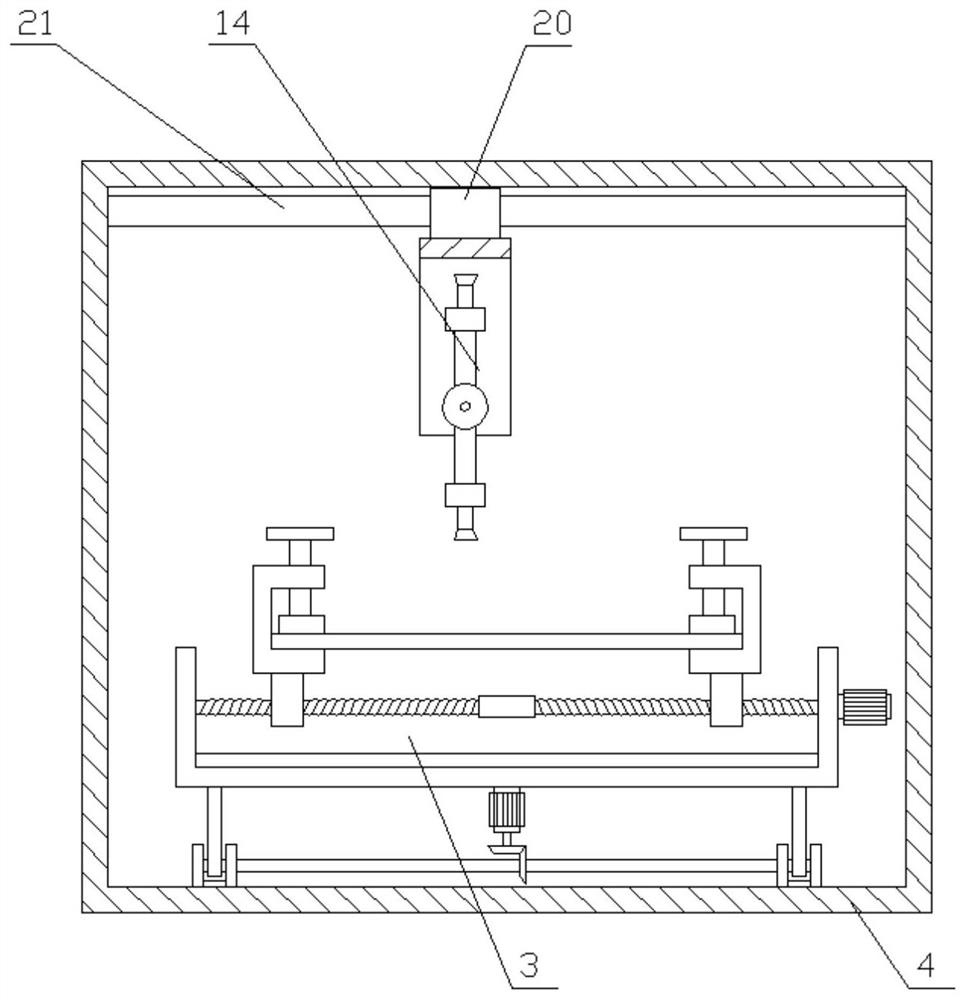

[0025] see Figure 1-2 , a kind of plate grinding and painting device for mechanical processing, comprising the first motor 12, the second motor 29, the third motor 33, telescopic cylinder 19, polishing machine 18, hot air blower 13 and casing 4, the output of the second motor 29 The end is fixedly connected with the third bevel gear 27, and the third bevel gear 27 meshes with the fourth bevel gear 28. The inlet 1 is arranged on the left side of the box body 4, and the hot air blower 13 is arranged on the upper side of the box body 4, and the right side of the box body 4 The paint box 9 is arranged on the side, the hot air blower 13 pipelines are connected to the hot air spray frame 7, and the pump pipeline is arranged in the paint box 9 to connect the paint spray frame 6, and the pump is used to pressurize the paint delivery, and the paint spray frame 6 and the hot air spray frame 7 are all Several nozzles 15 are set, which can increase the painting and drying area, and speed...

Embodiment 2

[0028] see figure 1 , The difference between this implementation and the above-mentioned embodiment 1 is that a protective door is provided in the middle of the box body 4, and the protective door is an electric push-close door, which can close the spray booth and prevent paint pollution.

[0029]The working principle of the present invention is: said a kind of plate grinding and painting device for mechanical processing, when using the device to polish and paint the plate, firstly according to the width of the plate, the third motor 33 is controlled to drive the threaded shaft 24 to rotate, supported by both sides The frame 23 clamps the side of the plate, then the upper surface of the plate is fixed by the compression bolt 22, the second motor 29 is controlled to rotate, the plate transport mechanism 3 is translated along the guide rail, and the grinding mechanism 17 is opened, controlled by the telescopic cylinder 19 The grinding disc 36 of the grinder 18 touches the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com