A method for preparing aluminum foil for pcb by casting and rolling slab

A casting and rolling, aluminum foil technology, applied in metal rolling and other directions, can solve the problems of high surface hardness, poor surface cleanliness, low heat dissipation efficiency, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

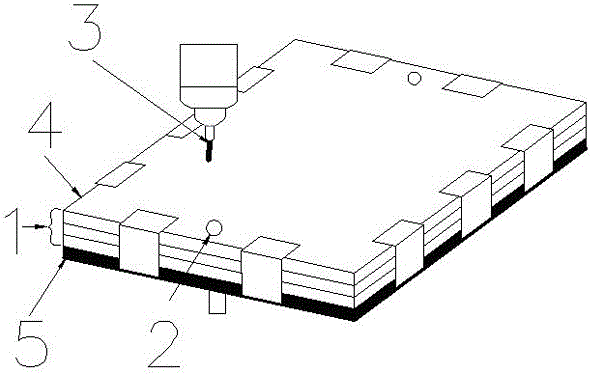

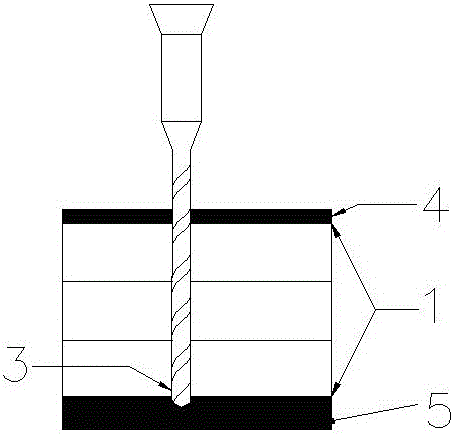

Image

Examples

Embodiment 1

[0033] The method for preparing aluminum foil for PCB by using a cast-rolled slab comprises the following steps:

[0034](1) Smelting, casting and rolling: 1050 aluminum alloy is used for smelting, casting and rolling into blanks, and the thickness of the blanks is 6.5-6.9mm. The process of smelting and casting and rolling must be clean of deslagging and degassing to ensure uniform composition. The melting temperature is less than 770°C, and the temperature of the guide furnace is 750±10°C. During the melting process, electromagnetic stirring is used to fully stir the melt to ensure uniform composition. During the casting and rolling process, the rotary blowing method is used for online degassing , and use 30 PPi+40 PPi two-stage plate filter method to filter the melt to ensure that the hydrogen content in the melt is ≤0.15ml / 100g.Al, and the vertical plate and production adopt a small casting and rolling area and a low rolling speed , to reduce the precipitation of supersatur...

Embodiment 2

[0041] The method for preparing aluminum foil for PCB by using a cast-rolled slab comprises the following steps:

[0042] (1) Smelting, casting and rolling: 1060 aluminum alloy is used for smelting, casting and rolling into blanks, and the thickness of the blanks is 6.5-6.9mm. The process of smelting and casting and rolling must be clean of deslagging and degassing to ensure uniform composition. The melting temperature is less than 770°C, and the temperature of the guide furnace is 750±10°C. During the melting process, electromagnetic stirring is used to fully stir the melt to ensure uniform composition. During the casting and rolling process, the rotary blowing method is used for online degassing , and use 30 PPi+50 PPi two-stage plate filter to filter the melt to ensure that the hydrogen content in the melt is ≤0.15ml / 100g.Al, and use small casting and rolling areas and low rolling speeds for vertical plates and production , to reduce the precipitation of supersaturated soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com