Rolling system with efficient cleaning function

A clean and functional technology, applied in the field of aluminum sheet rolling, can solve the problems of cleaning dead angle, complex structure, lack of material surface impurities, oil stain cleaning function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

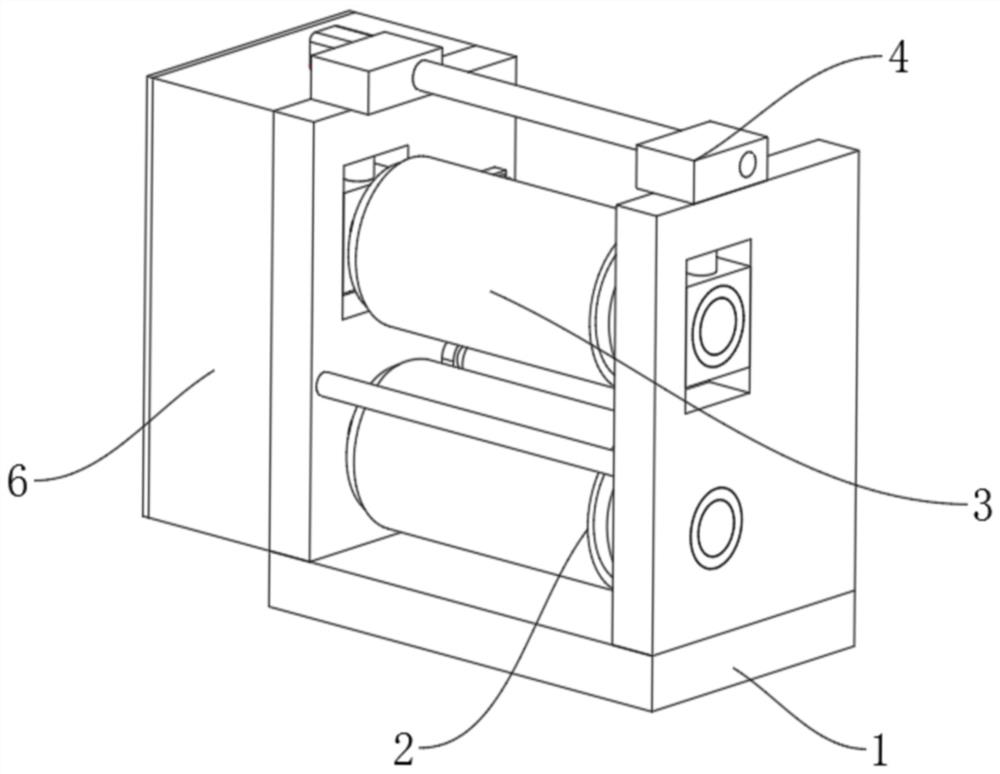

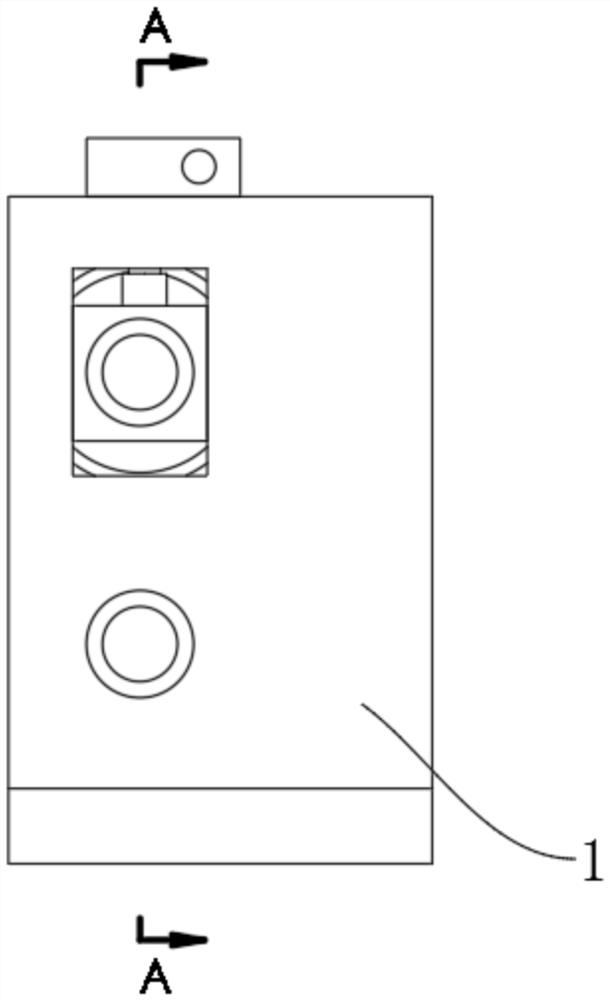

[0035] Embodiment one, such as Figure 1-6 As shown, a rolling system with high-efficiency cleaning function includes a frame 1, a lower roll 2, and an upper roll 3. A transmission box 6 is arranged on one side of the frame 1, and a horizontally arranged lower roll is fixedly installed on the inner side of the frame 1. 2. The front and rear of the lower roll 2 are provided with auxiliary support rolls 8 parallel to it. The roll 3 has the same diameter as the lower roll 2, and one end of the lower roll 2 and the upper roll 3 extends into the transmission box 6, and is connected with a transmission mechanism 5 that can make the lower roll 2 and the upper roll 3 synchronously and reversely rotate, and the transmission mechanism 5 is connected to the driving motor, and the rear sides of the lower roll 2 and the upper roll 3 are equipped with a cleaning mechanism 7, so that the material can be rolled through the upper roll 3 and the lower roll 2, and can also pass through the trans...

Embodiment 2

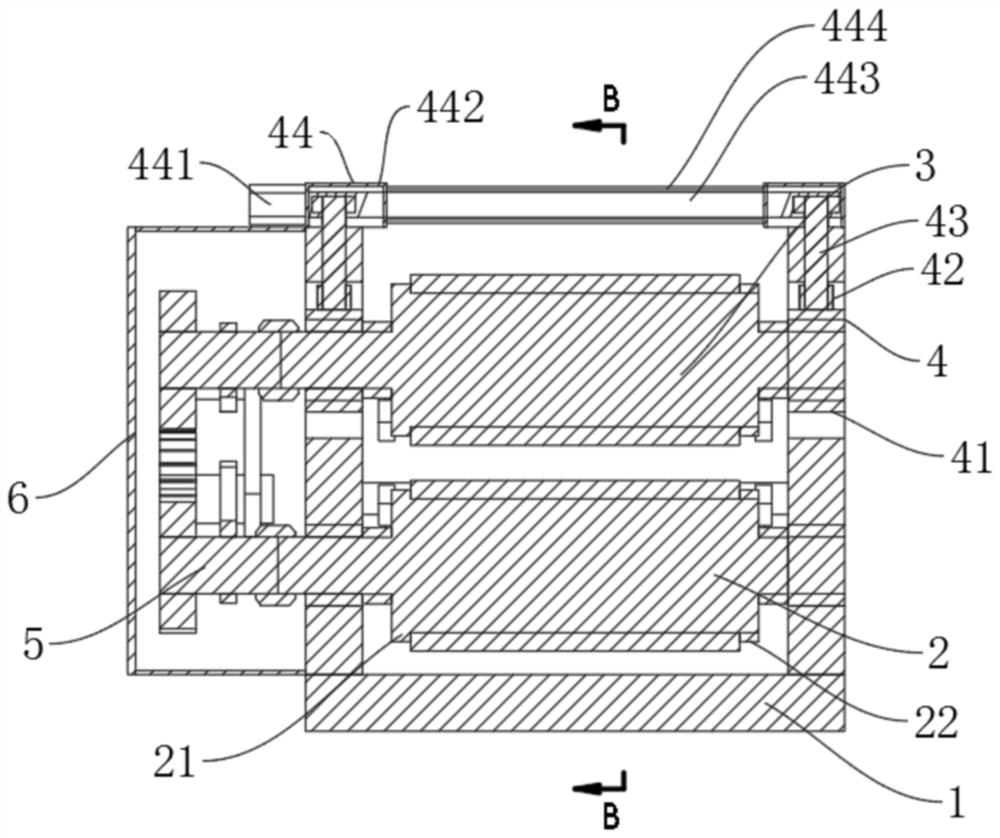

[0038] Embodiment two, on the basis of embodiment one, such as image 3 As shown, the two ends of the upper roll 3 are provided with an adjustment mechanism 4, the adjustment mechanism 4 includes a slide block 41, a threaded sleeve 42, and an adjustment shaft 43, and the inside of the two side walls of the frame 1 is provided with chutes arranged up and down. Slider 41 is slidably connected inside the groove, and slider 41 is connected with upper roller 3 through bearings. Threaded sleeve 42 is fixedly installed in the center of the top of slider 41, and a matching transmission screw is arranged inside the threaded sleeve 42. The transmission screw Set on the lower end of the adjustment shaft 43, the upper end of the adjustment shaft 43 extends out of the chute, and is connected with a drive assembly 44 that drives its rotation, so that the two adjustment shafts 43 can be driven to rotate by the drive assembly 44, and the adjustment shaft 43 rotates accordingly. , drive the th...

Embodiment 3

[0040] Embodiment three, on the basis of embodiment two, such as Figure 4 As shown, the fixed portion of the horizontal slide rail pair 76 in the cleaning mechanism 7 above is fixedly connected with the slide block 41 through the mounting bracket, and the central axis of the first cleaning roller 71 is on the same level as the central axis of the upper roller 3, so that The setting can make the cleaning mechanism 7 directly behind the upper roller 3 rise and fall with the lifting of the upper roller 3, and always ensure that the central axis of the first cleaning roller 71 is on the same level as the central axis of the upper roller 3, so that the first cleaning roller 71 The extrusion force on the upper roller 3 is completely a longitudinal force, the fixed part of the horizontal slide rail pair 76 in the cleaning mechanism 7 below is fixedly connected with the inner wall of the frame 1, and the central axis of the first cleaning roller 71 is in line with that of the lower ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com