Cleaning equipment of transmission belt in construction machinery

A transmission belt and cleaning equipment technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of transmission belt damage, poor cleaning effect, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

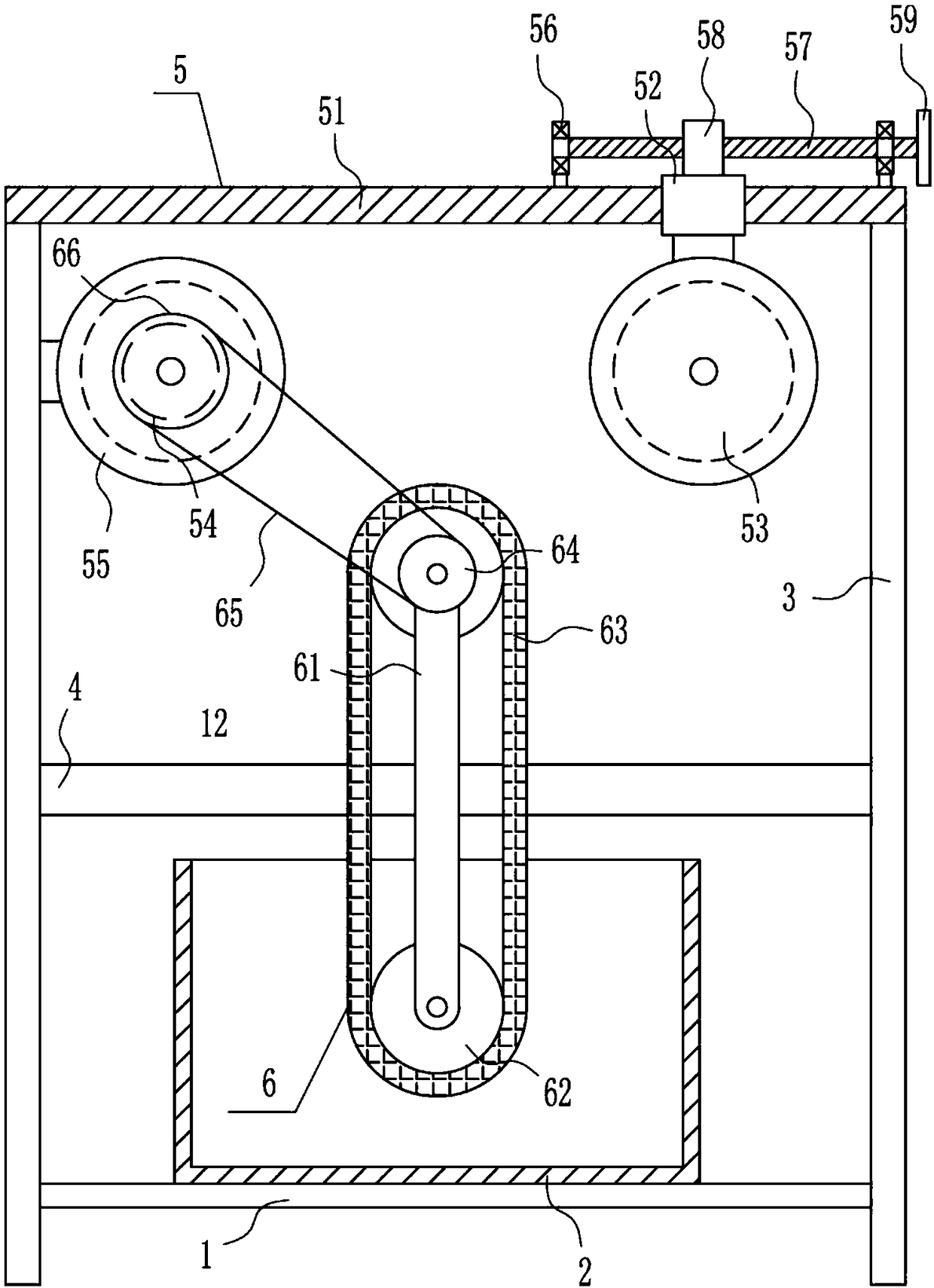

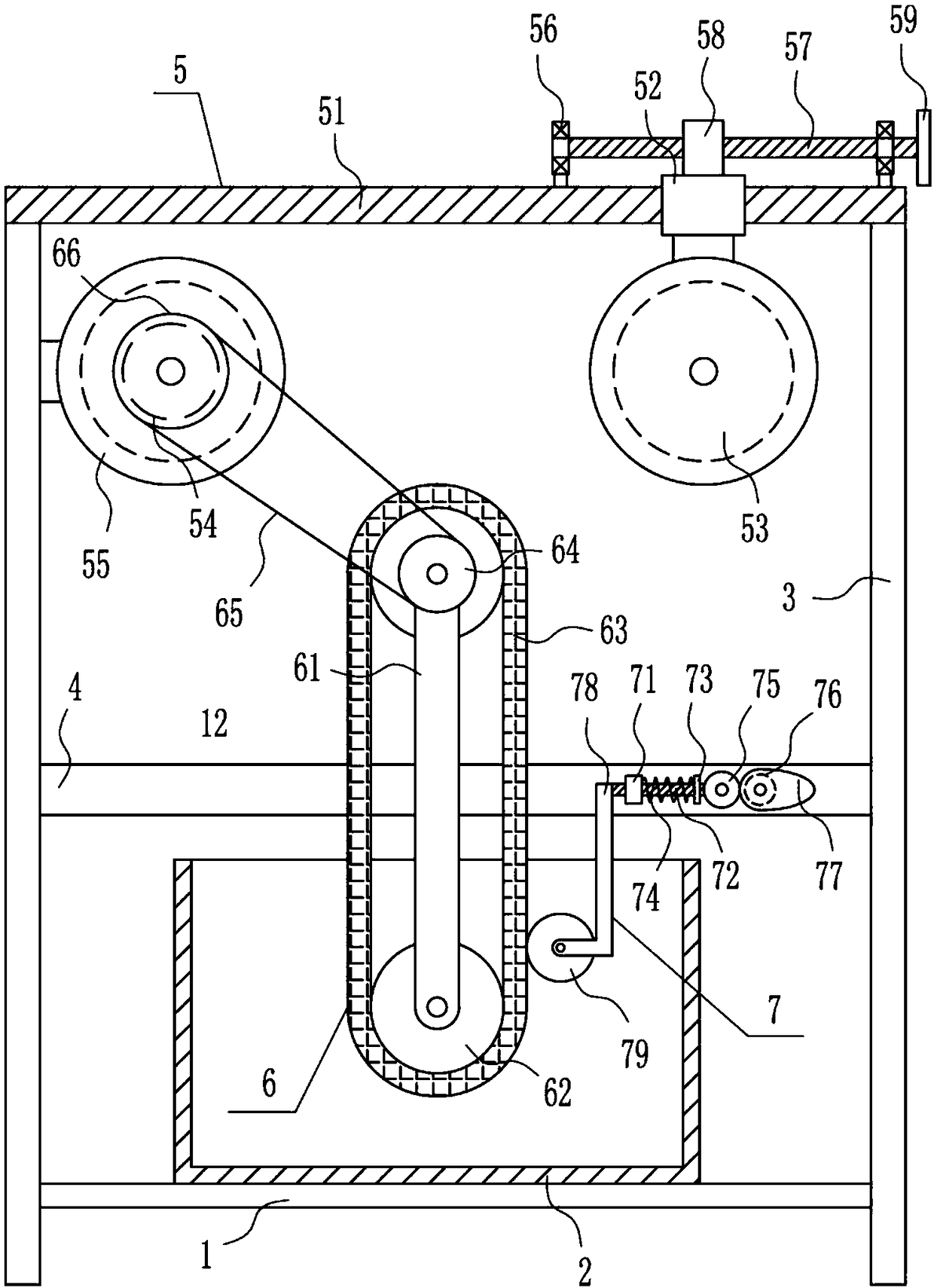

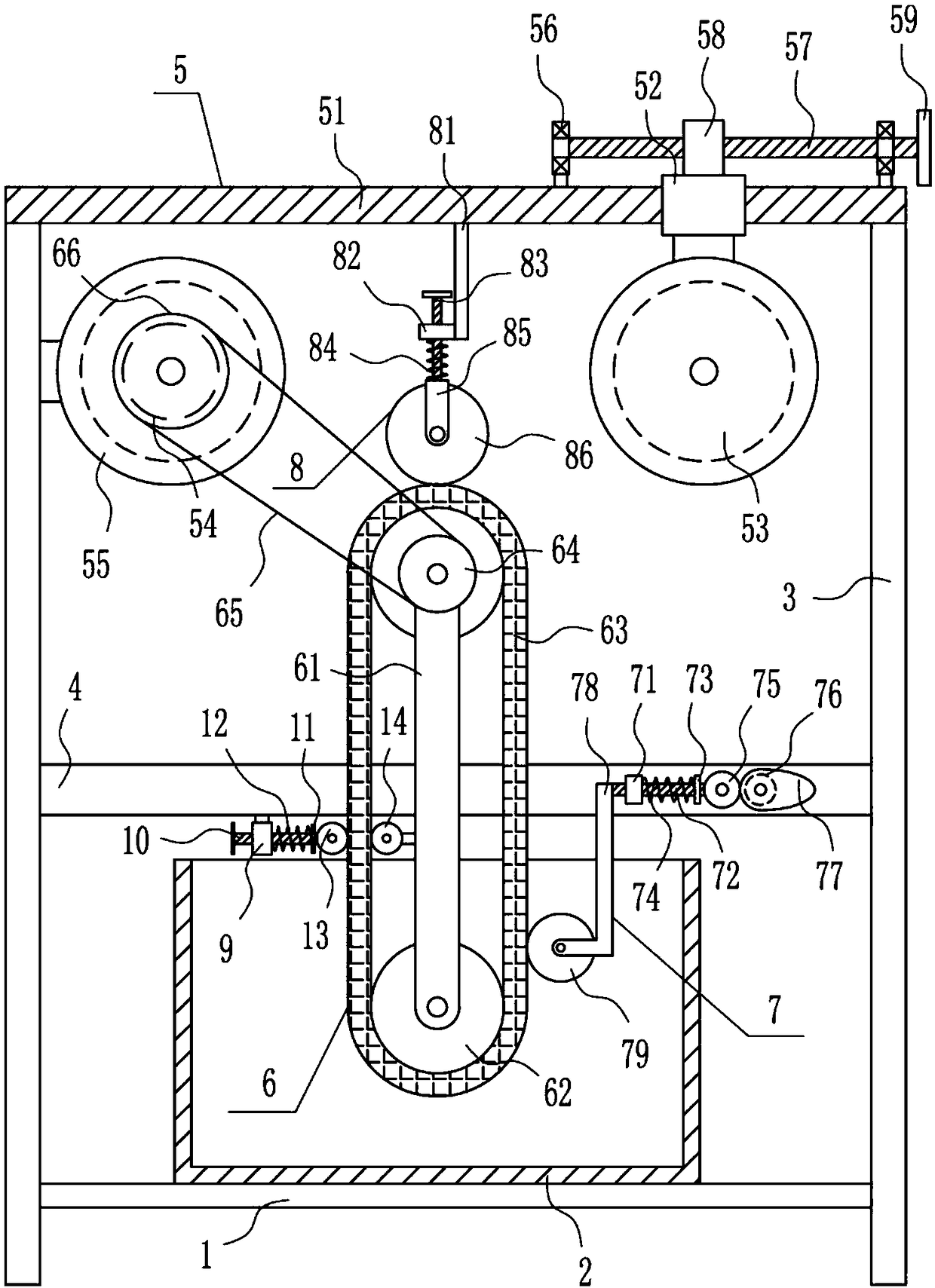

[0027] A construction machinery drive belt cleaning device, such as Figure 1-3 As shown, it includes a base plate 1, a frame body 2, a vertical plate 3, a cross bar 4, a rotating device 5 and a cleaning device 6. The frame body 2 is installed in the middle of the top of the base plate 1, and the left and right sides of the base plate 1 are installed with The vertical boards 3 and the vertical boards 3 are arranged symmetrically. A crossbar 4 is installed between the middle part of the right side of the left vertical board 3 and the middle part of the right side. A cleaning device 6 is provided between the middle parts of the front side of the cross bar 4 , and the lower part of the cleaning device 6 is located in the frame body 2 .

Embodiment 2

[0029] A construction machinery drive belt cleaning device, such as Figure 1-3 As shown, it includes a base plate 1, a frame body 2, a vertical plate 3, a cross bar 4, a rotating device 5 and a cleaning device 6. The frame body 2 is installed in the middle of the top of the base plate 1, and the left and right sides of the base plate 1 are installed with The vertical boards 3 and the vertical boards 3 are arranged symmetrically. A crossbar 4 is installed between the middle part of the right side of the left vertical board 3 and the middle part of the right side. A cleaning device 6 is provided between the middle parts of the front side of the cross bar 4 , and the lower part of the cleaning device 6 is located in the frame body 2 .

[0030] The rotating device 5 includes a slide rail 51, a slide block 52, a first sheave 53, a first motor 54, a second sheave 55, a bearing seat 56, a screw rod 57, a nut 58 and a torsion bar 59, and the left and right vertical plates 3 A slide ...

Embodiment 3

[0032] A construction machinery drive belt cleaning device, such as Figure 1-3 As shown, it includes a base plate 1, a frame body 2, a vertical plate 3, a cross bar 4, a rotating device 5 and a cleaning device 6. The frame body 2 is installed in the middle of the top of the base plate 1, and the left and right sides of the base plate 1 are installed with The vertical boards 3 and the vertical boards 3 are arranged symmetrically. A crossbar 4 is installed between the middle part of the right side of the left vertical board 3 and the middle part of the right side. A cleaning device 6 is provided between the middle parts of the front side of the cross bar 4 , and the lower part of the cleaning device 6 is located in the frame body 2 .

[0033] The rotating device 5 includes a slide rail 51, a slide block 52, a first sheave 53, a first motor 54, a second sheave 55, a bearing seat 56, a screw rod 57, a nut 58 and a torsion bar 59, and the left and right vertical plates 3 A slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com