Dehydrated vegetable pretreatment production line

A technology for dehydrated vegetables and pretreatment, applied in food processing, application, food science and other directions, can solve the problems of easy damage to vegetables, low cleaning efficiency, and inability to clean vegetables in time. Better cleaning effect and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

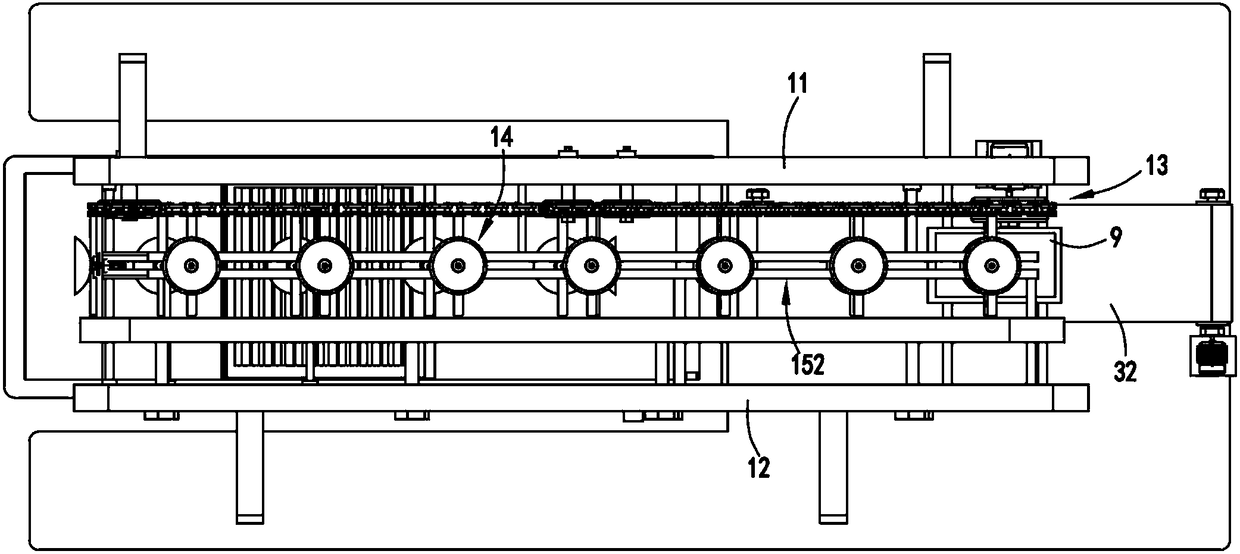

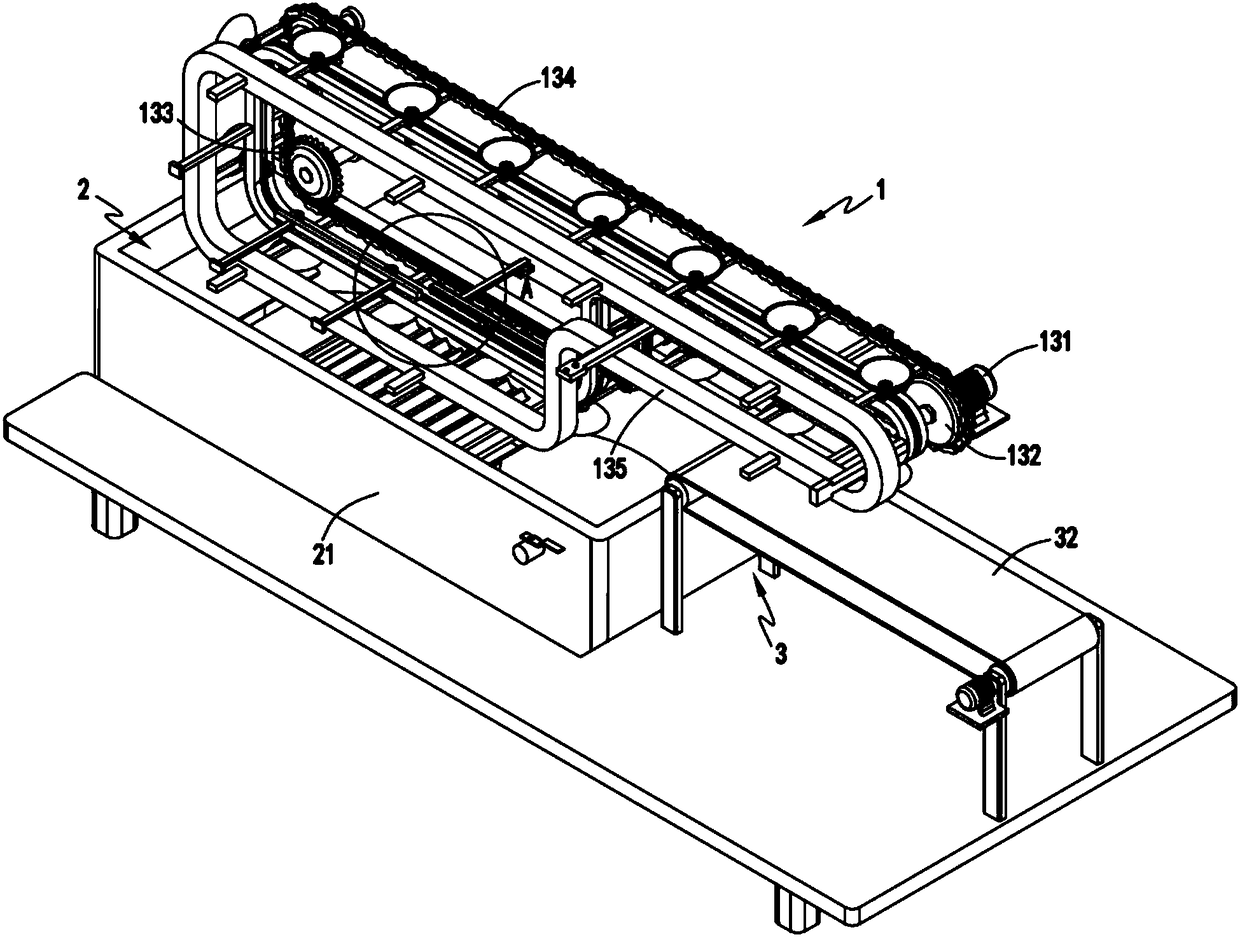

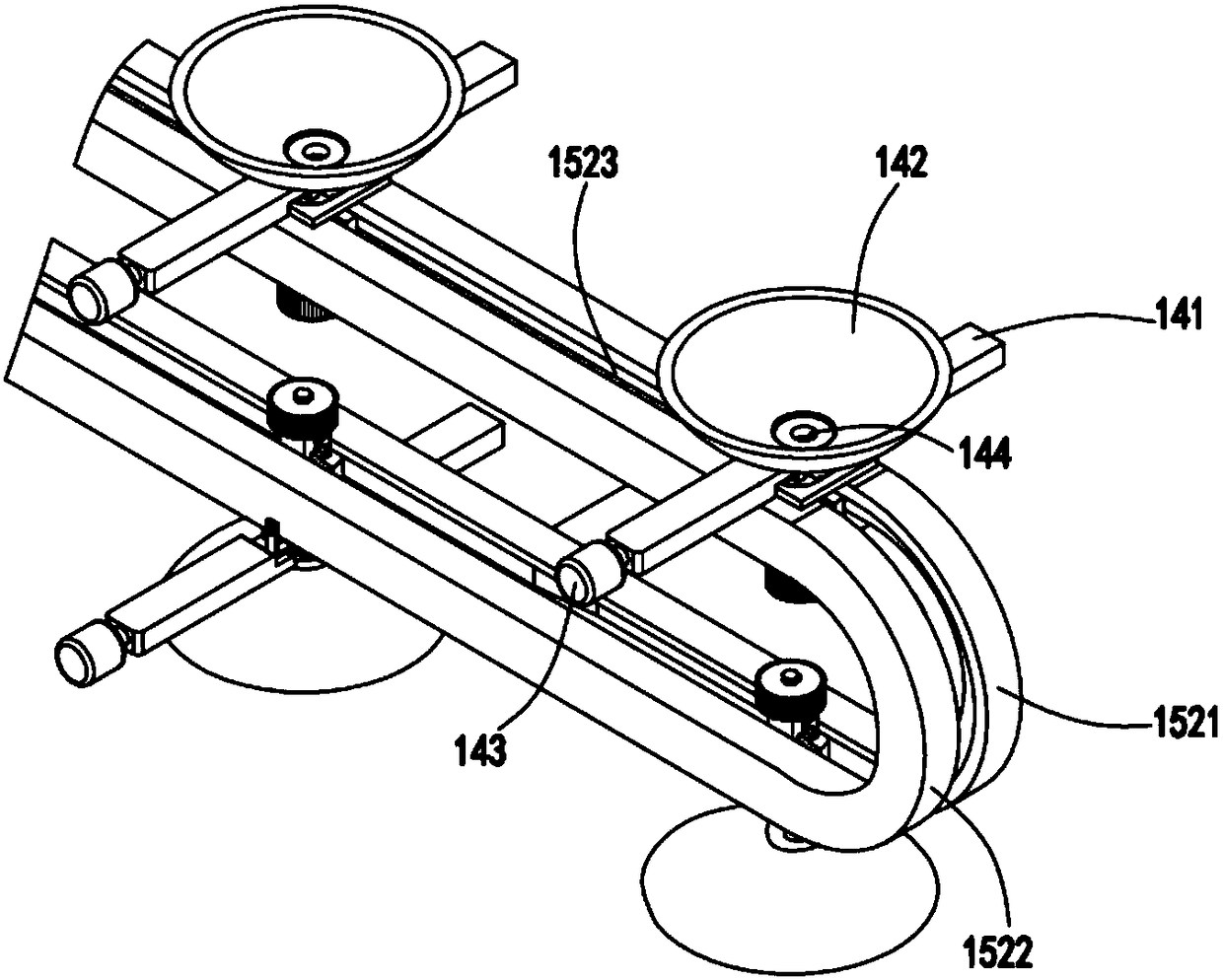

[0057] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 Shown, a kind of dehydrated vegetable pretreatment production line, comprises

[0058] Vegetable turning device 1, said vegetable turning device 1 includes a first bracket 11, a second bracket 12, a turning mechanism 13 arranged between the first bracket 11 and the second bracket 12, a rotating mechanism 13 for carrying Several supporting mechanisms 14 of vegetables and the clamping mechanism 15 arranged below the supporting mechanism 14 for fixing the vegetable roots on the supporting mechanism 14, the rotary mechanism 13 is used to drive the supporting mechanism 14 and the clamping mechanism 15 together with the vegetables make a rotary motion;

[0059] Cleaning device 2, described cleaning device 2 comprises water tank 21, is arranged on the top of water tank 21 a...

Embodiment 2

[0081] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: further, the clamping assembly 151 includes a clamping part a1511 and a clamping part b1512, the clamping part a1511 is provided with several slide bars 1513, the The clamping piece b1512 is provided with a sliding sleeve 1514 which is slidingly matched with the sliding bar 1513, and a spring a1515 sleeved on the sliding bar 1513 is provided between the sliding sleeve 1514 and the clamping piece a1511, and the clamping pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com