Large and medium-sized layered heating experiment device for anaerobic fermentation of coal and experiment method of layered heating experiment device

An anaerobic fermentation and experimental device technology, which is applied in the direction of fermentation, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of increased research and development costs and technical difficulties, large-capacity samples are difficult to be heated evenly, and experiments are difficult to be effective and stable Operation and other problems, to achieve good support and anti-compression effect, good guiding and sliding effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

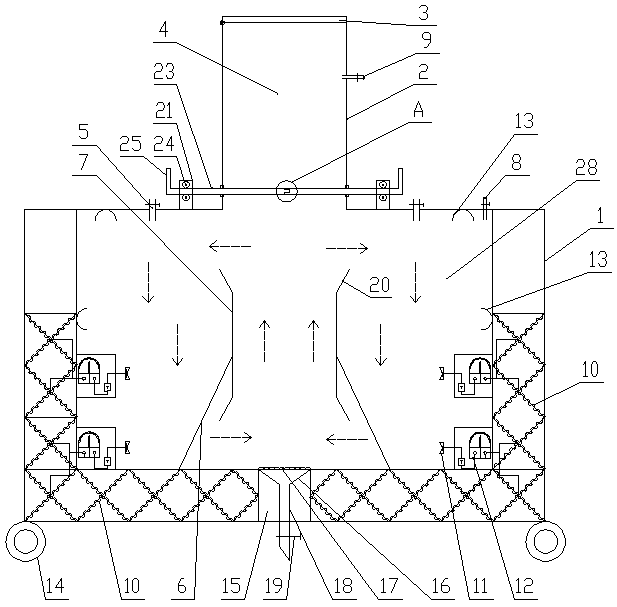

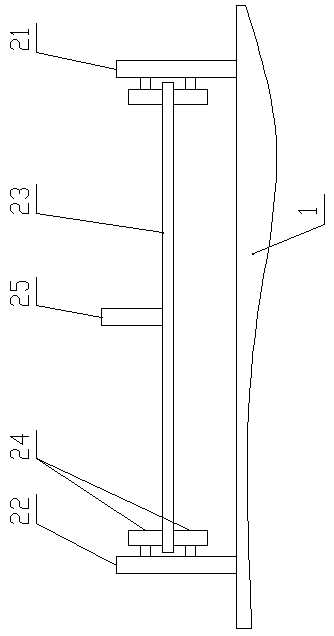

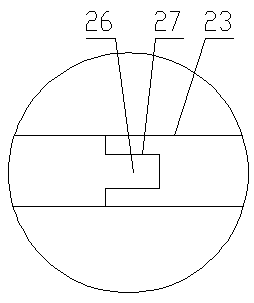

[0033] Such as figure 1 , figure 2 and image 3As shown, the large and medium-sized coal anaerobic fermentation layered heating experimental device of the present invention includes a cylindrical tank body 1, the center line of the tank body 1 is arranged along the vertical direction, and the top of the tank body 1 is fixedly arranged with a tank body 1 The lower barrel 2 is internally connected and on the same center line. The top of the lower barrel 2 is provided with a tank cover 3, and the lower part of the lower barrel 2 is equipped with a left and right horizontal push-pull stop mechanism and a right horizontal push-pull stop mechanism arranged symmetrically. The inside of the lower feeding barrel 2 is an enrichment culture area 4, the top of the tank body 1 is provided with several gas delivery ports 5 along the circumferential direction, the inner bottom of the tank body 1 is provided with a support 6 directly below the lower feeding barrel 2, and the support 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com