Multistage water spinning paint spraying cabinet

A water cyclone and spray booth technology, applied in the spray booth, spraying device, etc., can solve the problems of workers inhaling into the body, escaping, and affecting the health of workers, so as to improve the cleaning effect and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

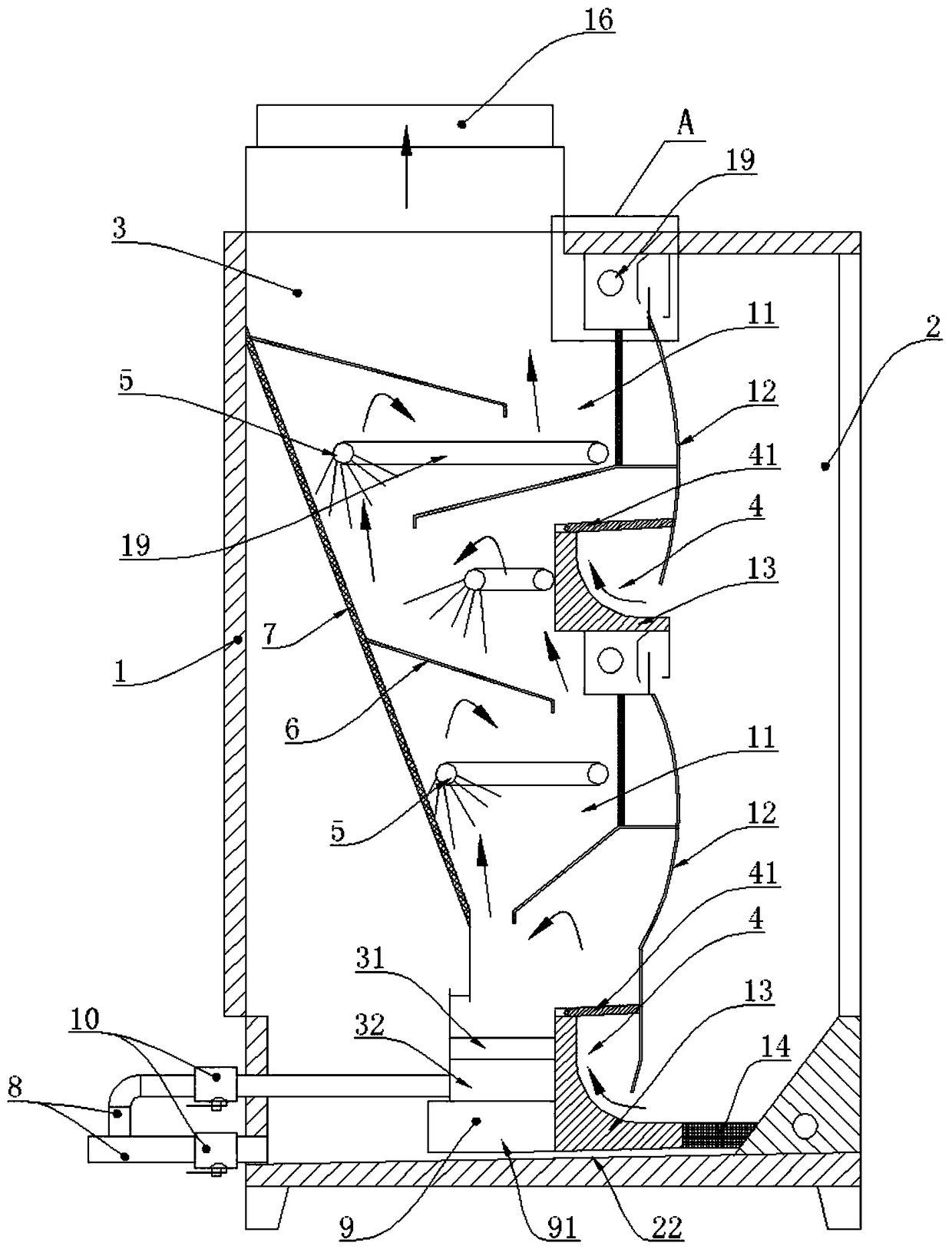

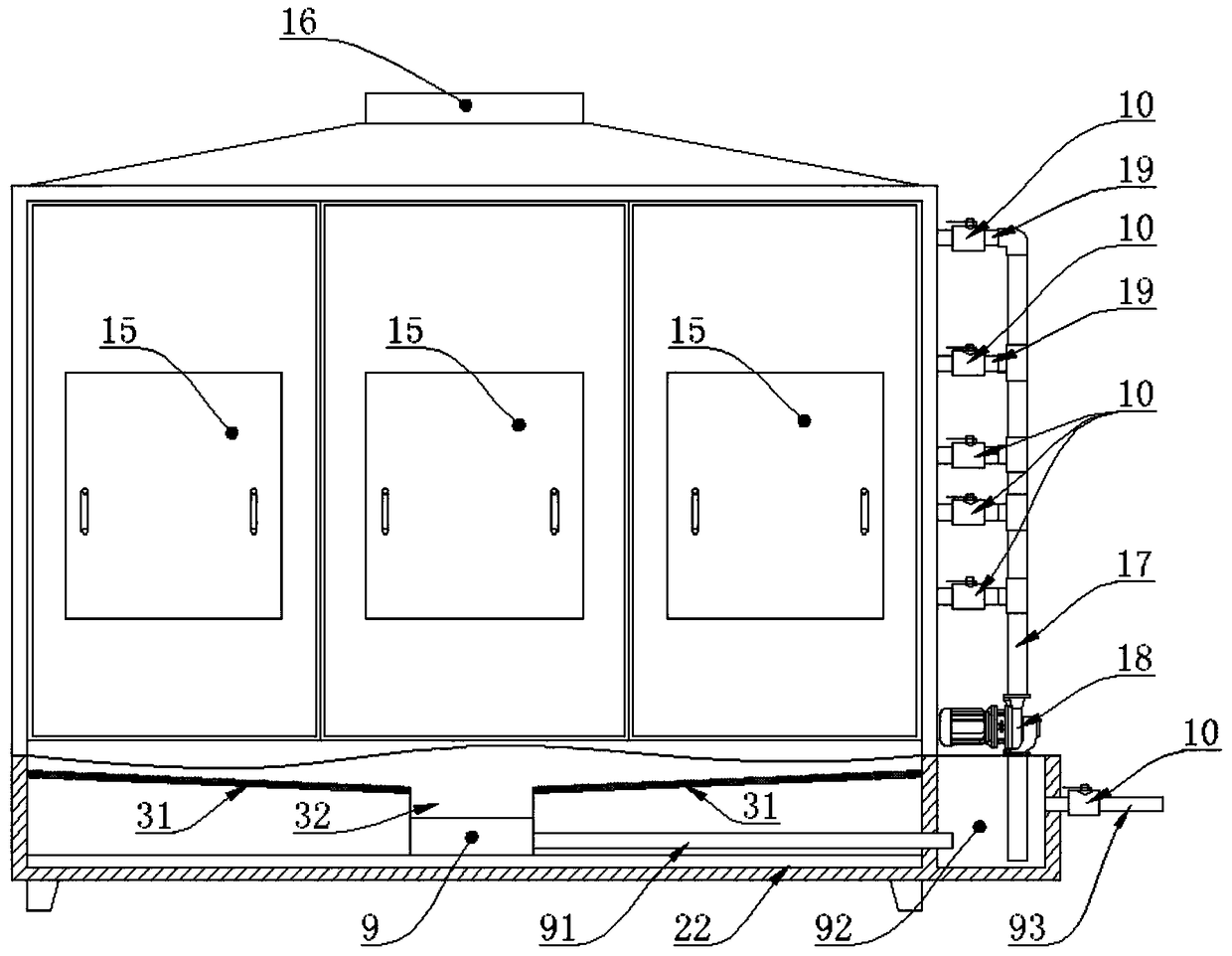

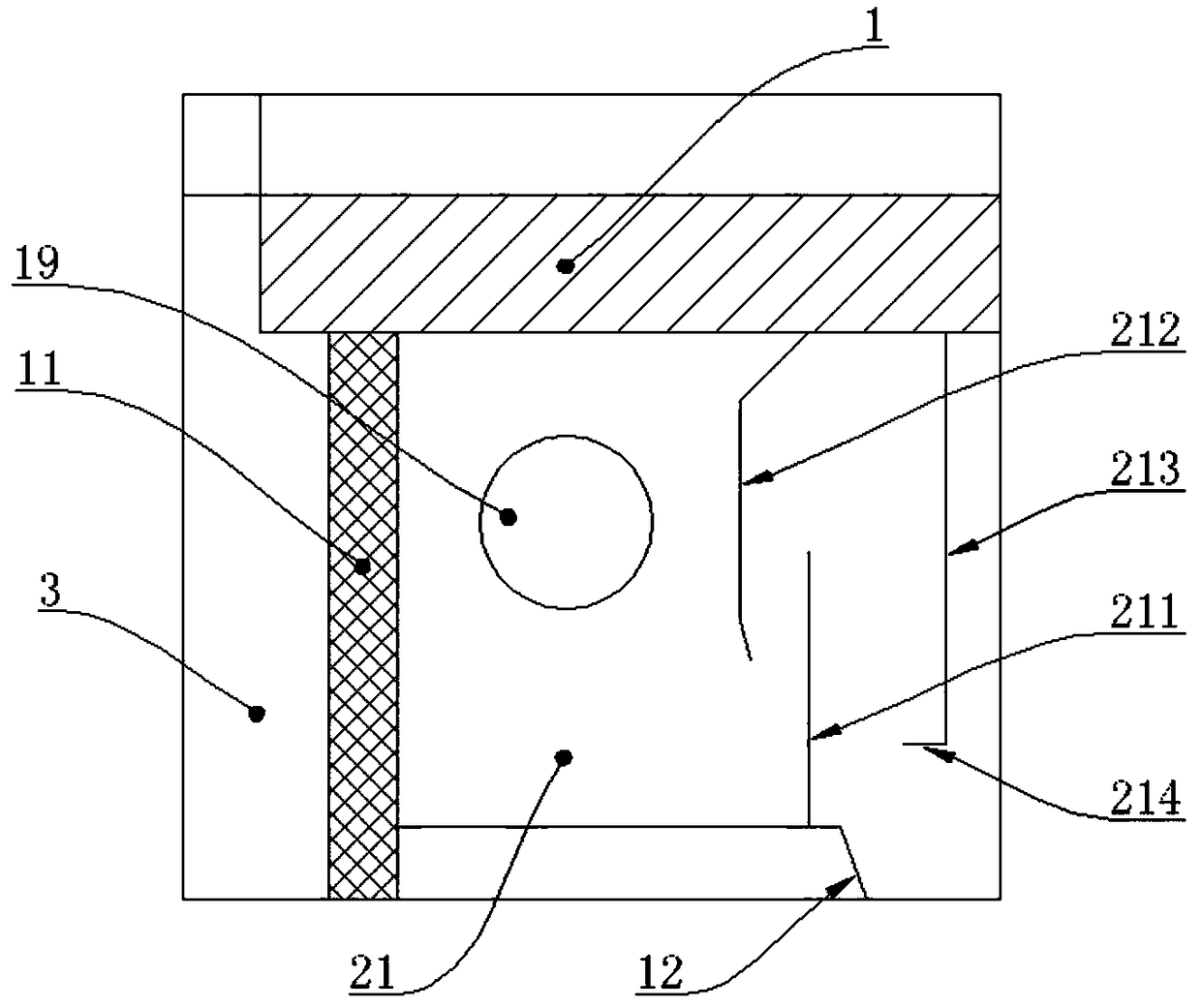

[0031] see Figure 1 to Figure 4 As shown, a multi-stage water cyclone painting cabinet includes a cabinet body 1 and a water curtain plate 11 fixedly arranged in the cabinet body 1. The water curtain plate 11 separates the cabinet body 1 to form a paint spraying room 2 and a reaction room 3. The spraying room 2 and the reaction chamber 3 are communicated through the air hole 4, the reaction chamber 3 is provided with a fan 16, the fan 16 extracts the waste gas in the reaction chamber 3, and makes the waste gas in the spray booth 2 enter the reaction chamber 3, and the air intake There is a water outlet tank 21 above the chamber. The liquid medicine in the water outlet tank 21 flows out and forms a water curtain for absorbing paint. This structure makes the exhaust gas fully contact with the liquid medicine, and the surface area of the water curta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com