Construction waste crushing device for constructional engineering and using method thereof

A construction waste and crushing device technology, which is applied in the field of construction engineering, can solve the problems of dust reduction and waste of water resources, and achieve the effects of reducing loss, saving water resources, and improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

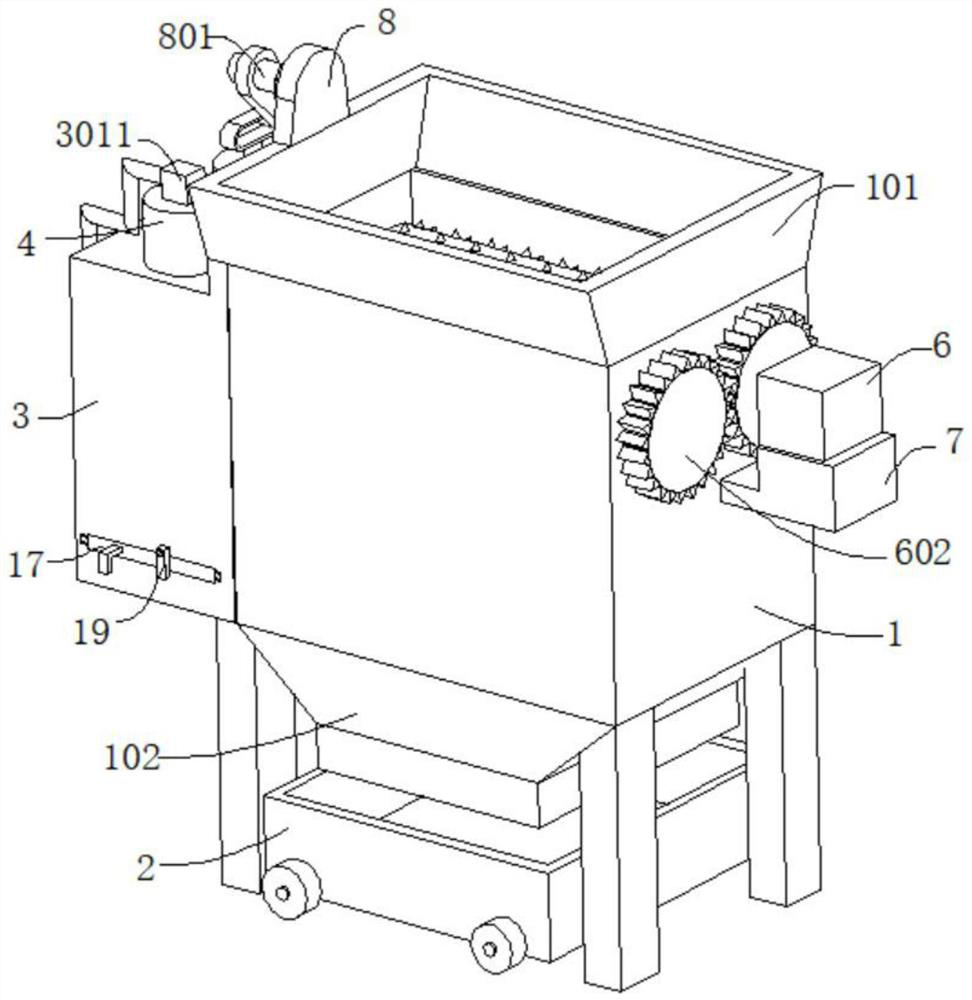

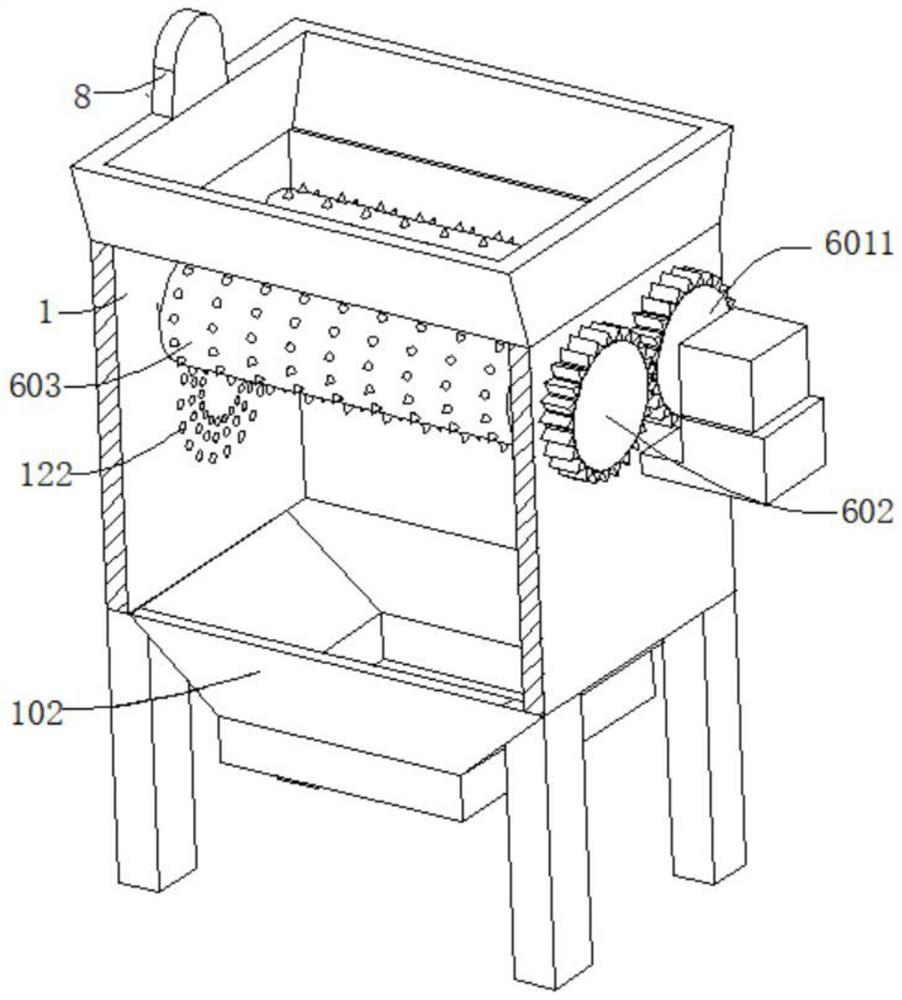

[0040] refer to Figure 1-4 , a construction waste crushing device for construction engineering, comprising a crushing box 1 and a garbage collection vehicle 2, the garbage collection vehicle 2 is placed at the bottom of the crushing box 1, and the upper and lower sides of the crushing box 1 are respectively connected with a material inlet 101 and a discharge Port 102, a crushing mechanism is connected to the crushing box 1, the dust suppression box 3 is connected to the outer wall of the crushing box 1, the water replenishment tank 4 and the sprinkler tank 5 are respectively connected to the dust suppression box 3, and the first The pipeline 401 and the second pipeline 402 are connected to the bottom of the dust suppression box 3 with a water delivery pipe 301, and the end of the water delivery pipe 301 away from the dust suppression box 3 is connected to the top of the water replenishment tank 4. The outer wall of the water delivery pipe 301 is connected to a water pump 3011,...

Embodiment 2

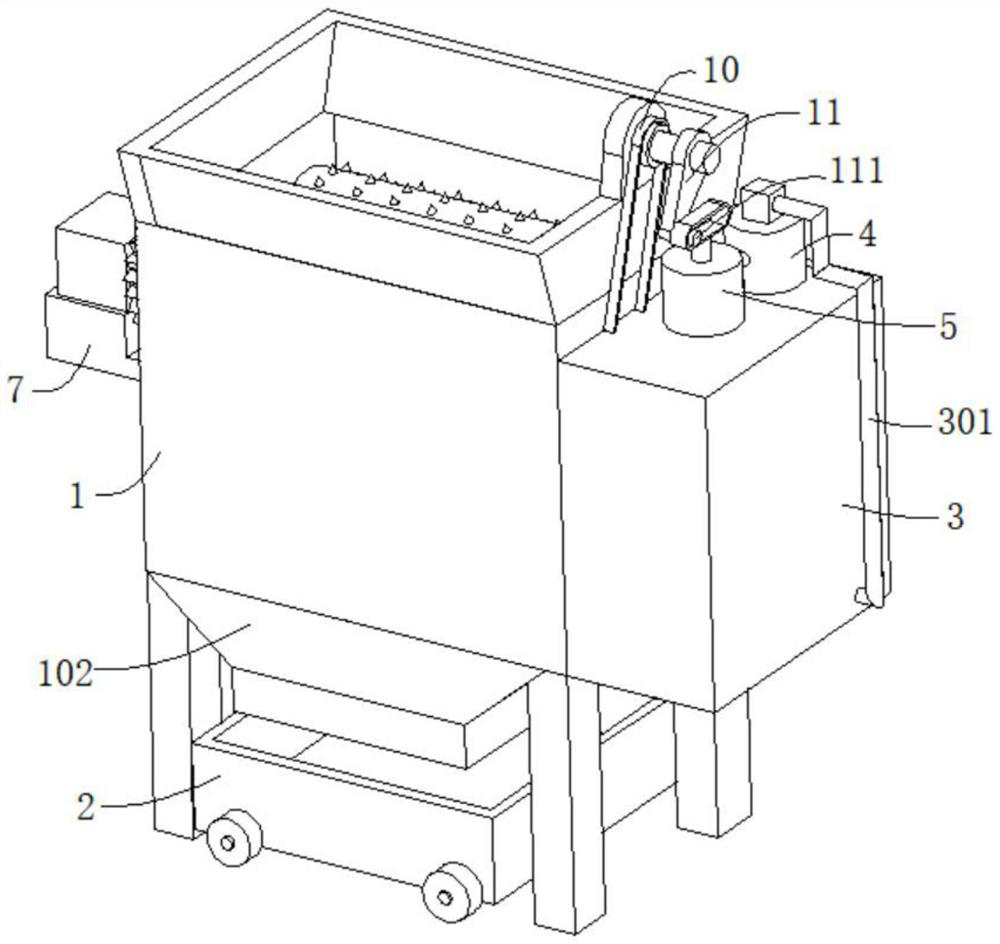

[0043] refer to Figure 1-7 , a construction waste crushing device for construction engineering, which is basically the same as that of Embodiment 1, furthermore, the outer wall of the feed port 101 is connected with a fixed plate 8, the outer wall of the fixed plate 8 is connected with a third rotating shaft 801, the first rotating shaft 601 and The outer wall of the third rotating shaft 801 is connected with the first synchronous wheel 9, the first synchronous belt 10 is connected between the two first synchronous wheels 9, the outer wall of the third rotating shaft 801 is connected with the rotating plate 11, and the outer wall of the rotating plate 11 is connected with a fixed rod 111, the inner wall of the sprinkler box 5 is movably connected with a piston 501, the outer wall of the piston 501 is connected with a push rod 502, the end of the push rod 502 away from the piston 501 is connected with a moving frame 503, and the outer wall of the moving frame 503 is dug with a ...

Embodiment 3

[0046] refer to Figure 1-7 , a construction waste crushing device for construction engineering, which is basically the same as in Embodiment 1. Further, the inner wall of the dust suppression box 3 is dug with a first chute 16, and the inner wall of the first chute 16 is slidably connected with a slider 161. The slider Elastic element 162 is connected between the bottom wall of 161 and the inner wall of first chute 16, and the outer wall of slide block 161 is movably connected with filter screen 163, and the end of filter screen 163 away from slide block 161 is connected to the inner wall of dust suppression box 3 by hinge, the second The outer wall of the four rotating shafts 121 is connected with a swing lever 22, and the swing lever 22 is movable against the filter screen 163; During the process, the filter screen 163 is squeezed intermittently, so that the filter screen 163 drives the slider 161 to slide in the first chute 16 and squeezes the elastic element 162. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com